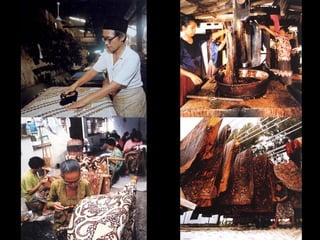

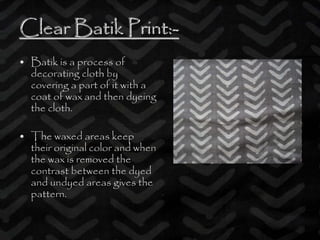

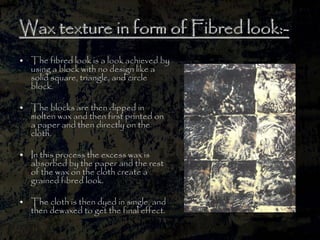

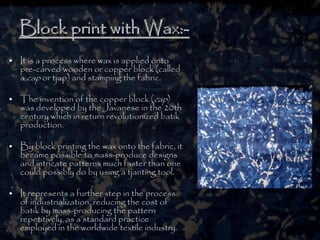

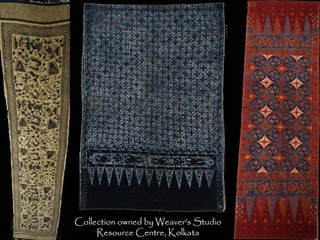

This document provides information about different textures of wax used in contemporary batik textiles. It discusses clear batik prints where the waxed areas retain the original color. It also describes wax prints that create a crackle effect from cracks in the wax during dyeing. Another texture mentioned is the fibred look achieved using solid blocks dipped in molten wax. The document also briefly outlines block printing with wax to resist dyes in certain areas of the fabric.