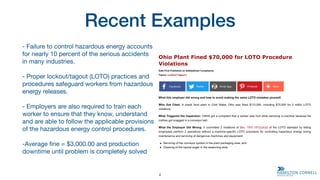

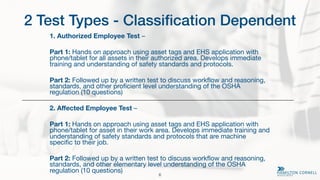

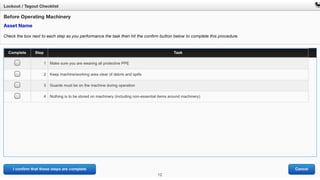

Hamilton Cornell collaborates with PTC to provide an IIoT EHS application focusing on employee training for OSHA LOTO compliance, emphasizing the risks and penalties associated with noncompliance. Training includes hands-on approaches and assessments for both authorized and affected employees to understand hazardous energy control procedures. The application offers benefits like plant-wide access to safety protocols, reduced onboarding time, and metrics on labor efficiency and asset tracking.