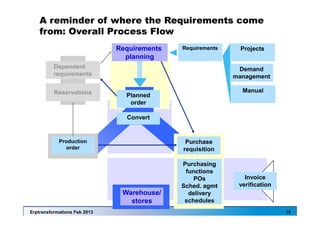

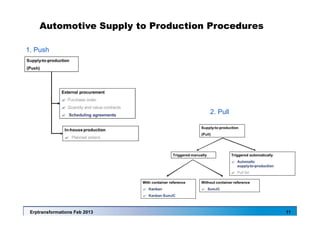

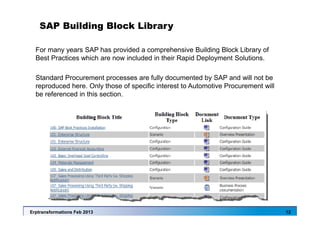

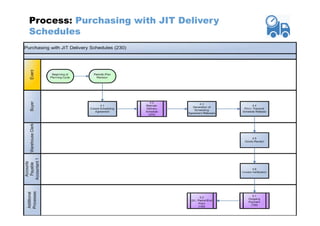

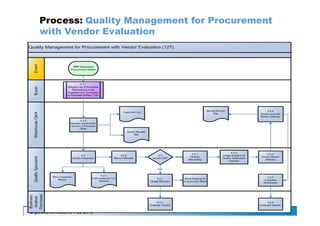

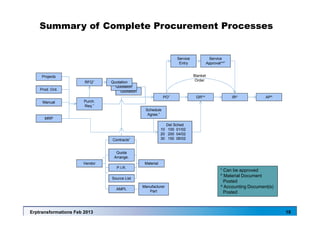

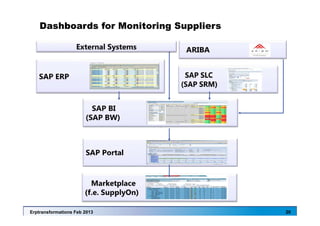

This document provides an overview of SAP automotive procurement processes implemented in a major car manufacturer. It discusses background on automotive procurement principles learned from previous experiences. Key principles from Chrysler and Honda around supplier relationships and total cost modeling are examined. The document then outlines standard SAP procurement processes and building blocks relevant for automotive procurement. Specific processes around purchasing with just-in-time delivery schedules and quality management/vendor evaluation are described. Finally, it summarizes the complete procurement process and discusses next steps around potential Ariba integration.