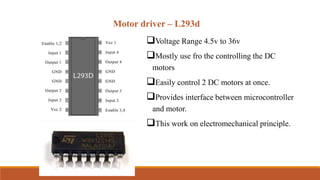

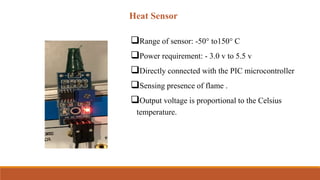

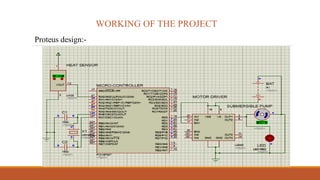

The document outlines a project to develop an automatic fire extinguisher robot aimed at enhancing safety and efficiency for firefighters. It details the objectives, components, functionality, and advantages of the robot, which uses a PIC microcontroller, various sensors, and a submersible pump to extinguish fires without human intervention. Additionally, it addresses the project's troubleshooting, applications, and future improvements, emphasizing its potential in hazardous fire situations.