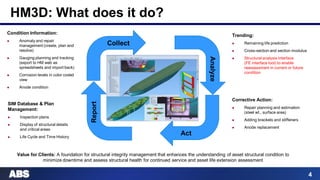

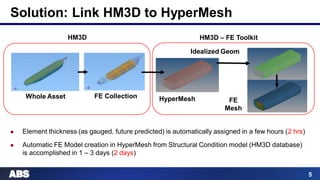

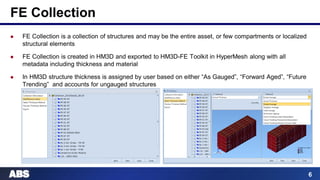

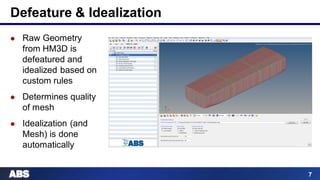

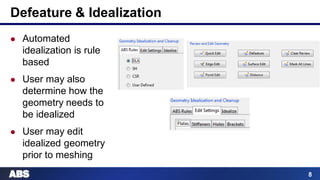

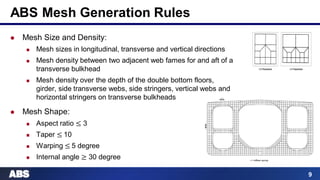

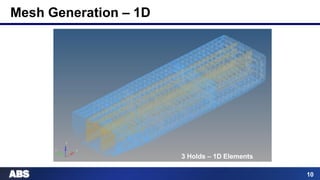

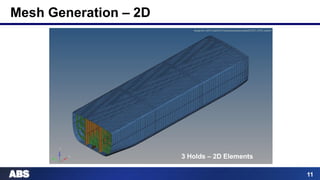

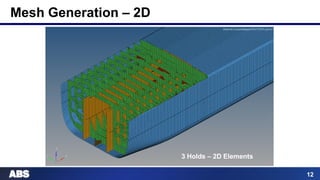

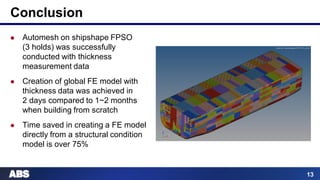

The document discusses advancements in automated finite element (FE) model creation for marine and offshore assets, which significantly reduce the time required for model updates and element thickness assignments from weeks to days. It also outlines the capabilities of the ABS Structural Integrity Management Suite, including the Hull Manager and the 3D modeling system (HM3D), which support asset condition tracking and anomaly management. The conclusion highlights a successful implementation of automesh on a shipshape FPSO, demonstrating a time savings of over 75% in creating global FE models.