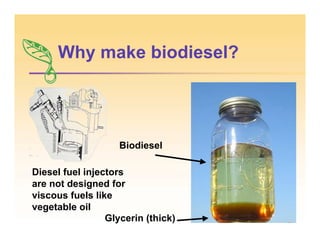

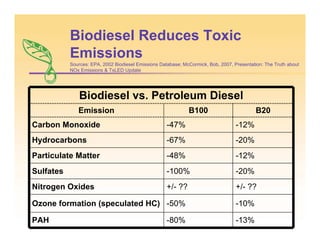

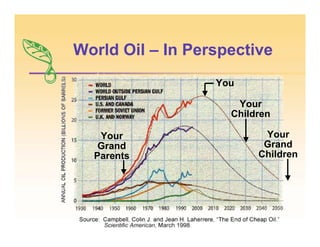

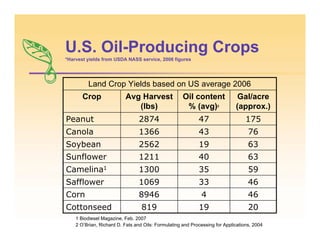

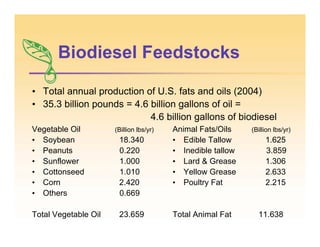

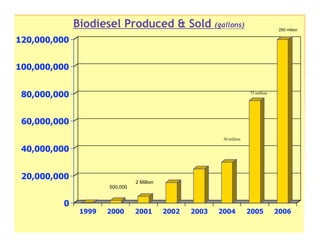

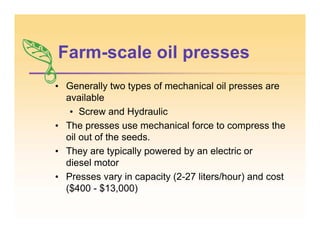

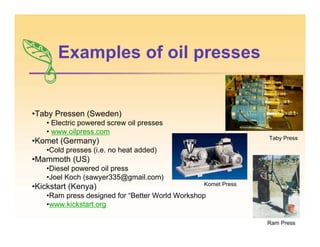

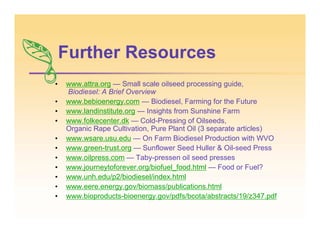

This document provides an overview of biodiesel production for agricultural producers. It discusses what biodiesel is, its history and chemistry. Key advantages include being biodegradable, renewable and reducing emissions. Common feedstocks like soybeans and canola are described. Small-scale production methods and case studies of on-farm biodiesel production are presented. Resources for further information are provided.