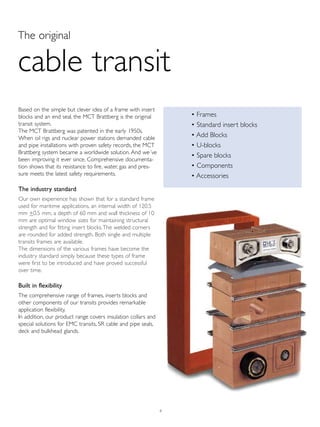

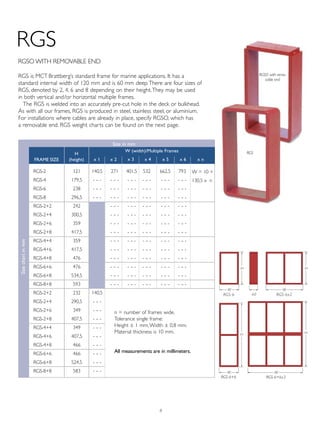

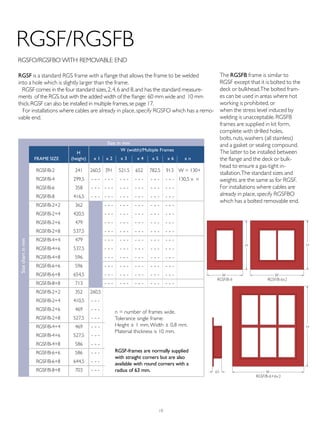

The document provides comprehensive information about MCT Brattberg's cable transit systems, highlighting their certified quality and safety standards for marine and building environments. It outlines the range of products including sealed transit systems, special products for specific applications, and membership in the MCT Brattberg Safety Club, which offers resources for installers. The document also details product specifications, testing certifications, and installation guidelines.