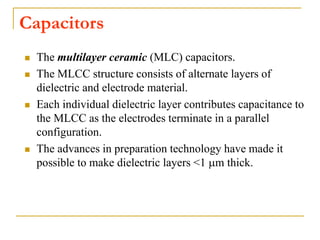

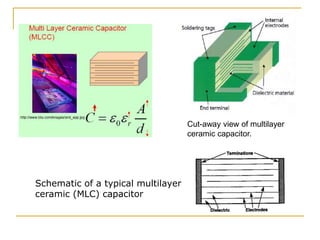

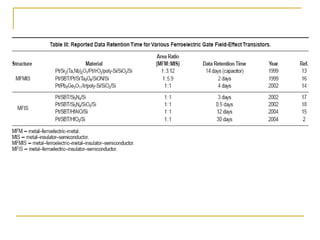

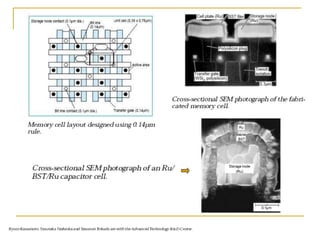

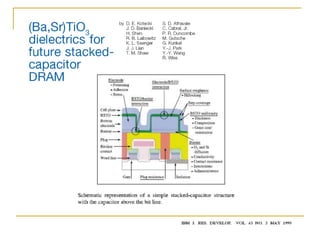

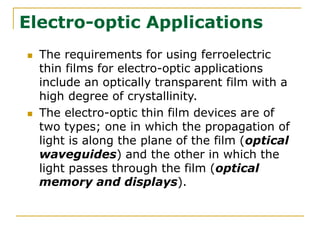

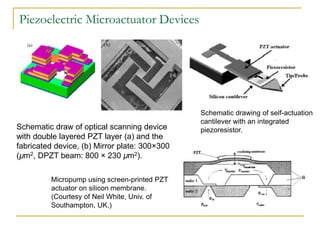

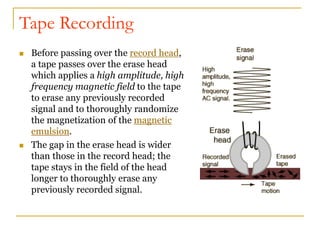

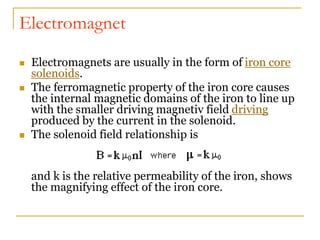

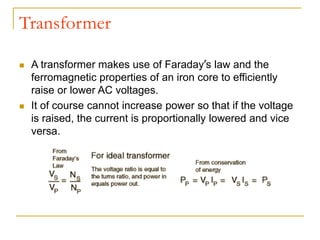

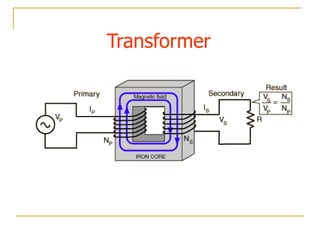

This document discusses various applications of electroceramics and magnetic materials. It describes how multilayer ceramic capacitors use thin dielectric layers to achieve high capacitance density. Ferroelectric thin films have applications in nonvolatile memories, capacitors, sensors, and optical devices due to their dielectric, piezoelectric and electro-optic properties. Ferromagnetic materials find use in transformers, electromagnets, recording media, and sensors. The document outlines the operating principles and advantages of these various electroceramic and magnetic applications.