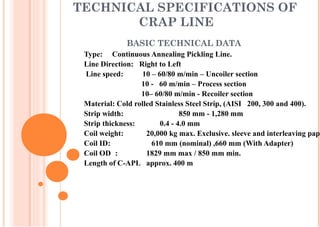

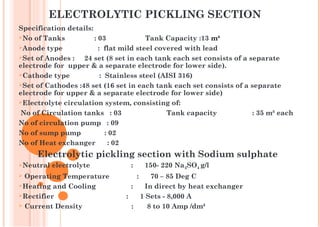

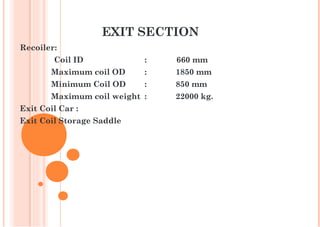

This document provides technical specifications for a continuous annealing pickling line (C-APL) used to process cold rolled stainless steel strips. It includes details on the line configuration from the uncoiler section to the recoiler section, specifications for the welding, degreasing, furnace annealing, quenching, pickling and exit sections. It also provides operating parameters for tension, line speed, furnace temperatures for different strip thicknesses and stainless steel grades, and electrolytic and mixed acid pickling bath compositions.