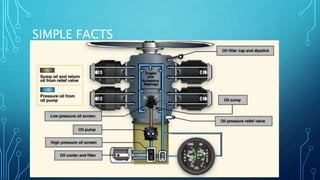

There are two main types of aircraft oil systems: wet-sump and dry-sump. A wet-sump system contains oil in a sump that is integral to the engine, while a dry-sump system contains oil in an external tank. Both systems circulate oil through pumps, but a dry-sump uses additional scavenge pumps to return oil to the external tank. Pilots monitor oil pressure and temperature gauges during flight to check the system and identify any issues like low oil quantity or blocked lines.