This document summarizes the design of a small business jet capable of intercontinental travel. Key specifications include a range of 2,500 nautical miles, capacity for 8-10 passengers, and cruise speed and altitude of 485 knots and 45,000 feet respectively. The aircraft design was refined over multiple iterations, evaluating factors such as weight estimation, airfoil selection, wing geometry, stability, and performance. Design goals included high reliability, 24-hour readiness, and the ability to operate safely on one engine. Historical business jet data was also analyzed to ensure the design followed industry trends.

![27

B

H

h

b

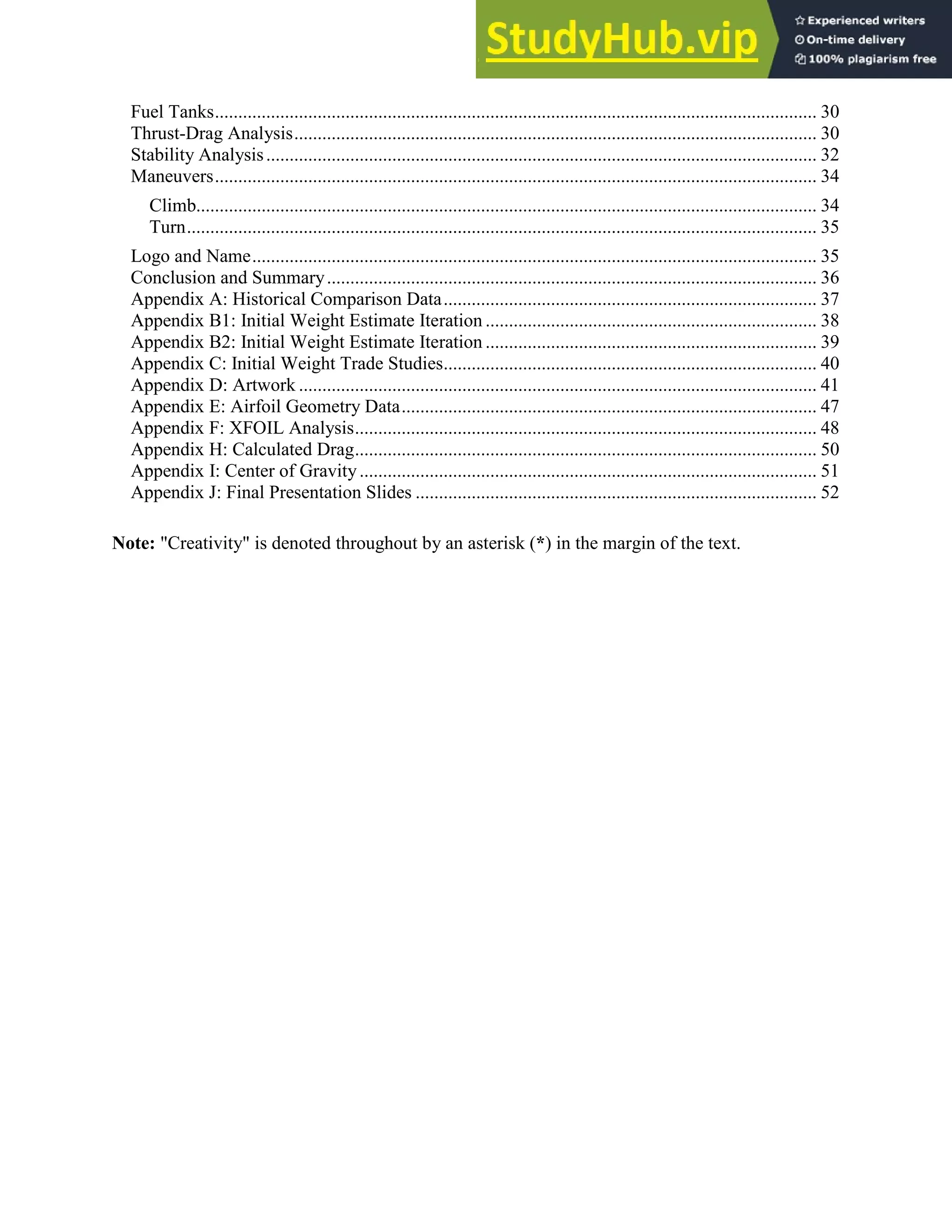

Winglets improve aerodynamic efficiency by reducing drag (they help to dissipate

wingtip vortices, a contributor to induced drag at wingtips, and increase Oswald efficiency by

around 10%). Only zero-lift drag increases marginally, because of a small increase in wetted area

(we account for this when required in this report).

The handling benefits offered by winglets are numerous, too: rudder yaw control

improves, heading overshoot is reduced, and stall speeds are lower.

Our winglets are depicted below:

Figure 17: Winglets

Structural Analysis

Research into the nature of composite (carbon fiber) materials in aviation yielded the

discovery that composite wings support loads in a markedly different manner than conventional

aluminum construction. The skin of a carbon fiber aircraft is much

more capable of supporting loads than an aluminum skin would be,

and so the interior structure is very different.

Without the tools at our disposal to completely alter the way

we conduct structural analysis, we have elected to use a box spar,

which, to a limited degree, simulates the skin effect and also the

tube spars used in some carbon fiber aircraft. Our composite spar is

depicted here.

The area of the spar

is BH – bh. Its moment of

inertia is:

[ ]

For structural analysis, we used an elliptic

loading, which is characterized by a distribution as

follows:

√ ( )

With a total aircraft weight of 14,543 kg, the load supported by each wing at cruise is

(14543 / 2) * 9.81 = 71,262 newtons. A safety factor of 3.5 is used henceforth.

Properties of carbon fiber

λ 275 GPa

ρ 1.75 g/cm3

Tensile strength 3.5 GPa

Compressive strength 1.25 GPa

Poisson's ratio 0.69

Shear modulus 15.15 GPa

Shear strength 55.15 MPa

Young's modulus 234.4 GPa

Front: Side: Top:

*

Figure 18: Box spar](https://image.slidesharecdn.com/aircraftdesignreport-230806184739-0cb0c8ea/75/Aircraft-Design-Report-27-2048.jpg)

![34

The total weight for the above components is 14535 kg, very close to our W0 estimate of 14543

kg. This yields a CG location of 9.58 m. Details are in Appendix I: Center of Gravity.

The simplest assessment of stability can be conducted:

Does ̅̅̅̅̅ ̅̅̅̅̅ ̅̅̅̅̅?

Our values satisfy this relation, and our aircraft is therefore stable in its pitch axis. A graphical

representation of the above relation is presented here (to avoid cluttering up our drawings

elsewhere):

Figure 25: Stability diagram

The distance between xnp and xmf is 1.06 m, or 37.8% of our aircraft's mean aerodynamic chord.

The static margin,

̅

works out to 0.253, which is greater than zero, again indicating a stable design.

Maneuvers

Climb

We used the following equations to determine our aircraft's climb characteristics:

Climb angle: [ ]

Climb rate: [ ]

Our aircraft's resulting climb angle is 3.54˚. This corresponds to a climb rate of 15.42 m/s

or 3030 fpm. At this climb rate, our aircraft reaches its cruising altitude of 45,000 ft in

approximately 15 minutes, assuming a takeoff at sea level.

Research performed by NASA indicates that winglets, as used on our aircraft, can

dramatically improve rate of climb. Below 5,000 ft, winglets can raise ROC by 6%, and above

*](https://image.slidesharecdn.com/aircraftdesignreport-230806184739-0cb0c8ea/75/Aircraft-Design-Report-34-2048.jpg)