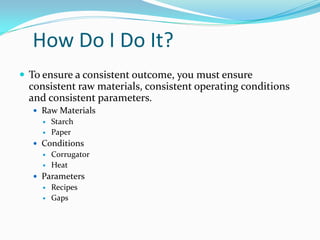

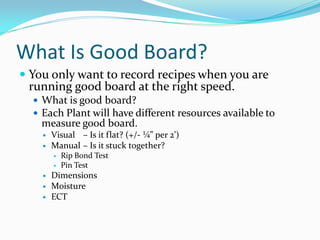

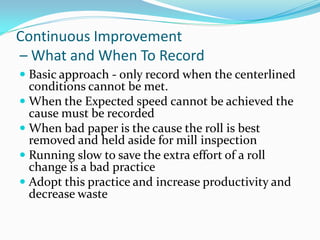

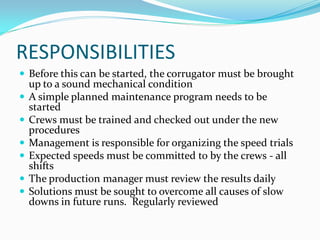

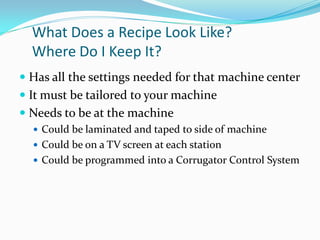

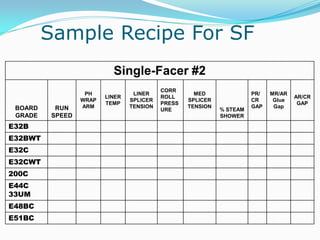

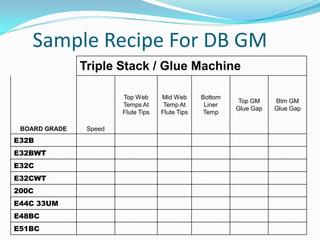

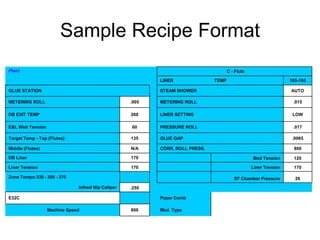

Centerlining is a process to reduce variability and consistently produce quality product. It involves ensuring consistent raw materials, operating conditions, and parameters. Recipes are developed through trials to determine the optimal machine settings and speeds needed to produce good quality board. All relevant information is recorded on a recipe sheet kept at the machine for reference.