Embed presentation

Downloaded 90 times

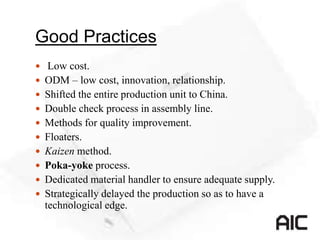

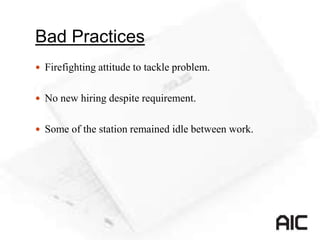

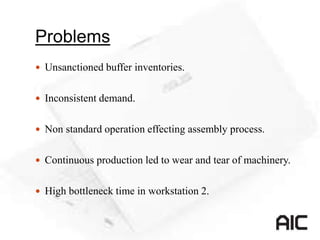

The document discusses the good and bad practices as well as problems and solutions related to the production of AIC Netbooks. Some good practices included working with ODM partners for low costs and innovation, quality improvement methods, and ensuring adequate material supply. Bad practices were a firefighting attitude to problems and idle production stations. Problems consisted of inconsistent demand and non-standard operations affecting assembly. Solutions proposed adding production lines, hiring more workers, implementing JIT and preventative maintenance.