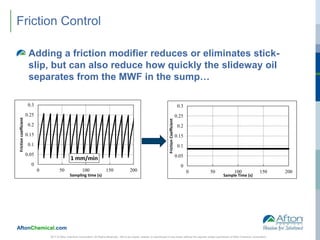

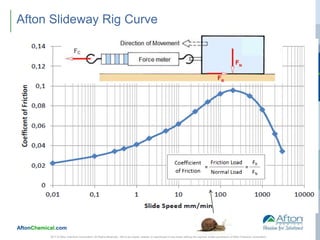

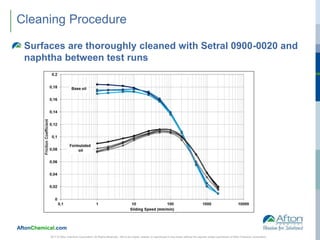

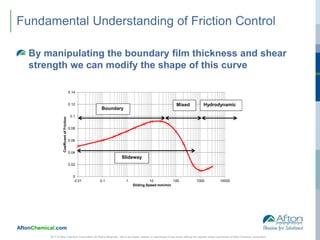

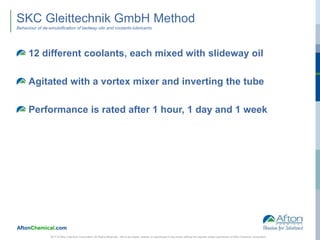

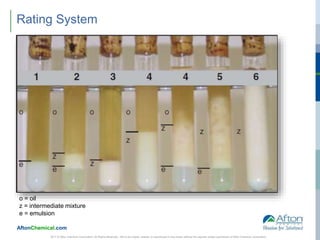

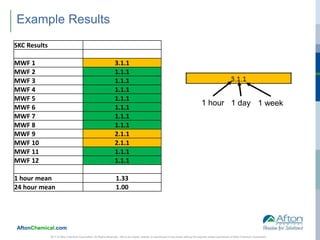

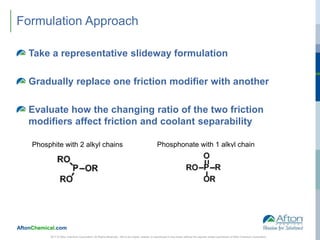

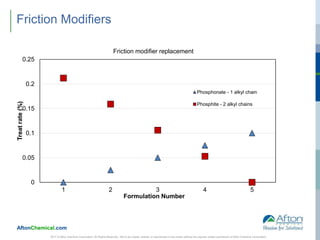

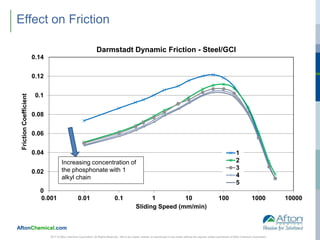

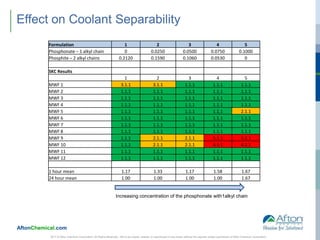

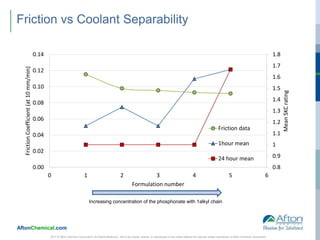

The document discusses the importance of friction control and coolant separability in slideway lubricants used in metalworking operations, emphasizing the need for formulations that maintain both properties. It details methods for measuring these parameters and presents findings from various tests on slideway oils and their compatibility with metalworking fluids. Key conclusions highlight that optimized formulations can effectively balance friction reduction and coolant life preservation.