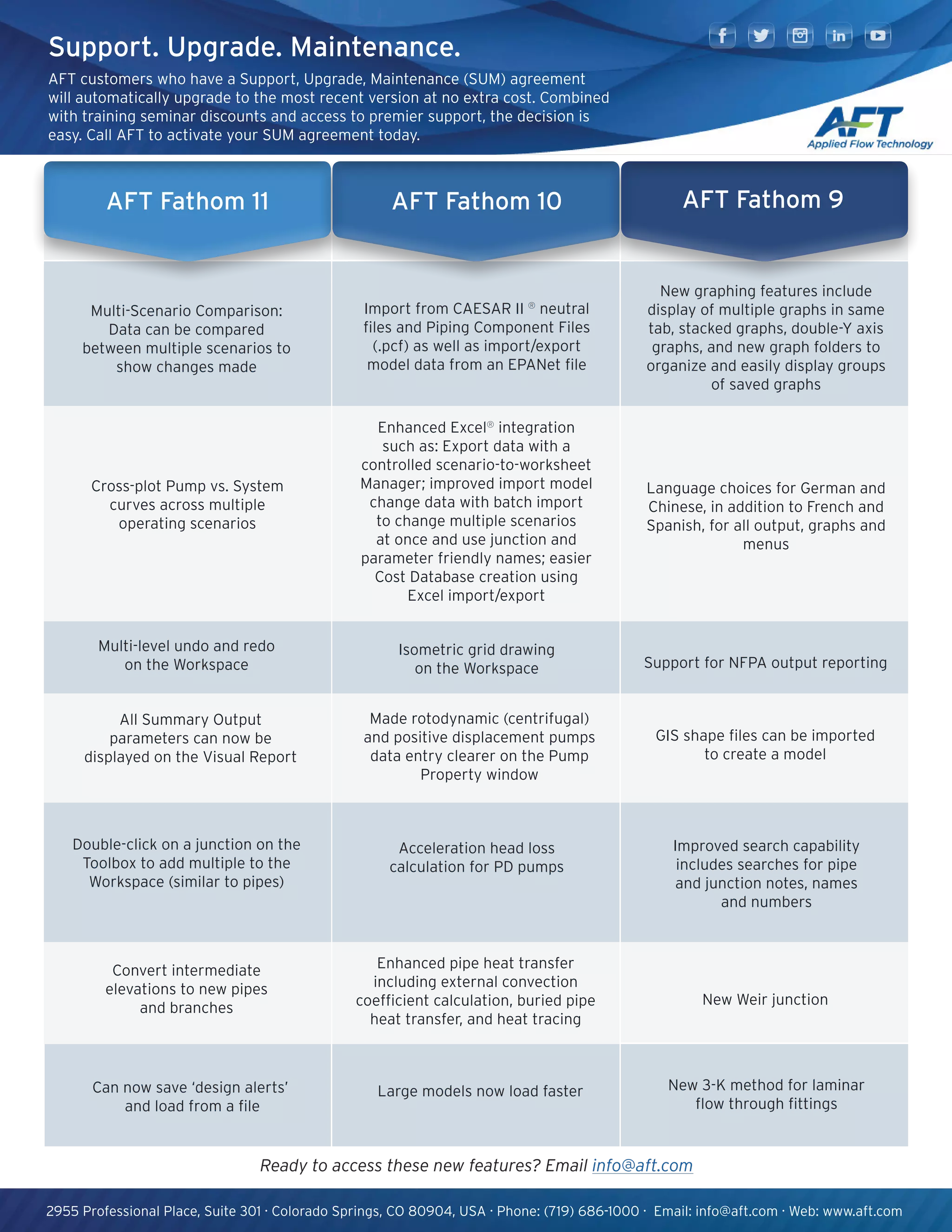

The document outlines the new features of AFT Fathom 11, including enhanced Excel integration, improved import/export capabilities, and new graphing features. It also highlights user-friendly functionalities such as multi-scenario comparisons, improved search capabilities, and customizable output options. AFT customers with a support, upgrade, maintenance agreement will receive automatic updates at no extra cost.