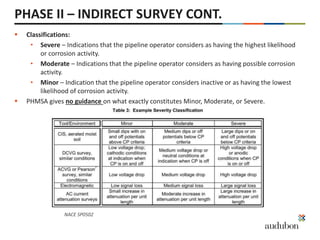

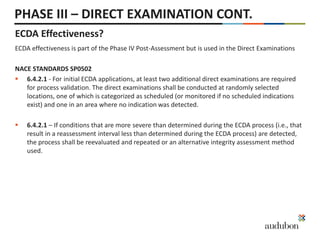

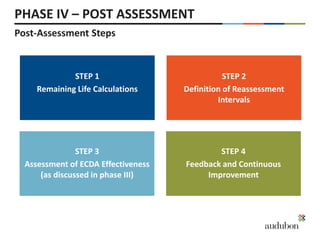

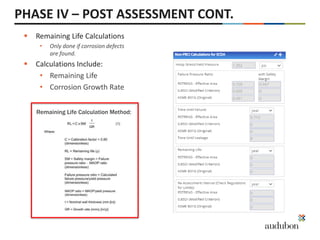

The document provides an overview of external corrosion direct assessment (ECDA). It summarizes the four phases of ECDA: pre-assessment, indirect inspection, direct examination, and post-assessment. The pre-assessment phase involves collecting pipeline data and selecting indirect inspection tools. Indirect inspections are then performed to identify corrosion indications, followed by direct excavations to validate findings. Finally, the post-assessment phase includes calculations, defining reassessment intervals, and continuous improvement. The presentation is delivered by Matthew Myers, an experienced pipeline integrity and corrosion expert.

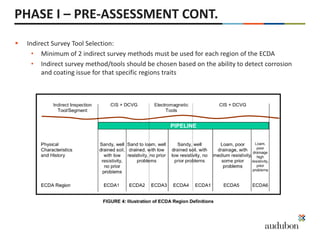

![TABLE 2: ECDA TOOL SELECTION MATRIX

1= Applicable: Small coating holidays (isolated and typically <600 mm2 [1 in.2]) and conditions that do not cause

fluctuations in CP potentials under normal operating conditions.

2= Applicable: Large coating holidays (isolated and continuous) or conditions that cause fluctuations in CP

potentials under normal operating conditions.

3= Not Applicable: Not applicate to this tool or not applicable to this tool without additional considerations.

NACE SP0502 Table 2: ECDA Tool Selection Matrix](https://image.slidesharecdn.com/afsexternalcorrosiondirectassessmentecda05-210506211334/85/External-Corrosion-Direct-Assessment-ECDA-11-320.jpg)