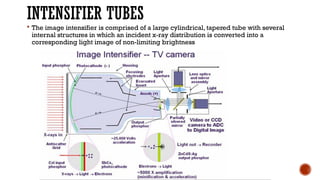

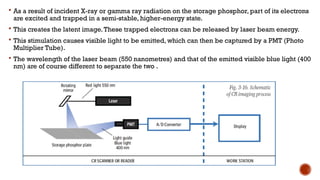

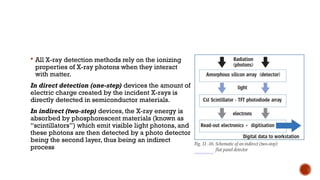

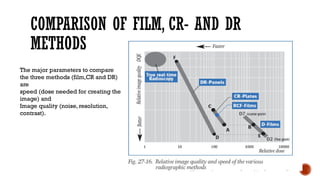

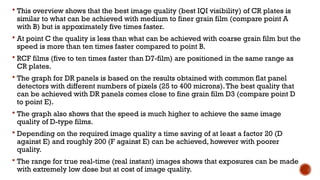

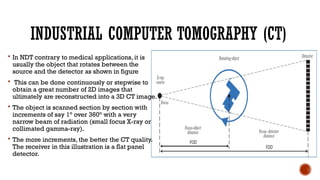

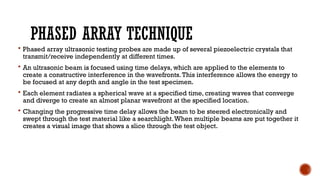

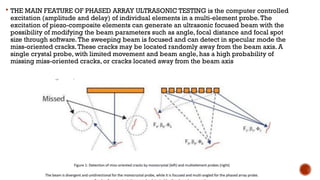

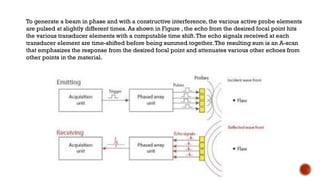

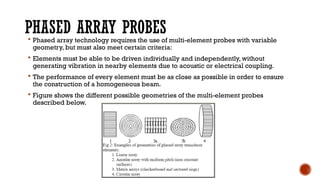

The document provides a comprehensive overview of various imaging techniques including image intensifiers, digital radiography, computed radiography, and computer tomography, explaining their fundamental principles, advantages, and applications. It highlights the comparison of conventional film, computed radiography (CR), and direct radiography (DR) in terms of speed, image quality, and operational efficiency. Additionally, it discusses advanced techniques such as phased array and synthetic aperture focusing to enhance ultrasonic imaging and defect detection in materials.