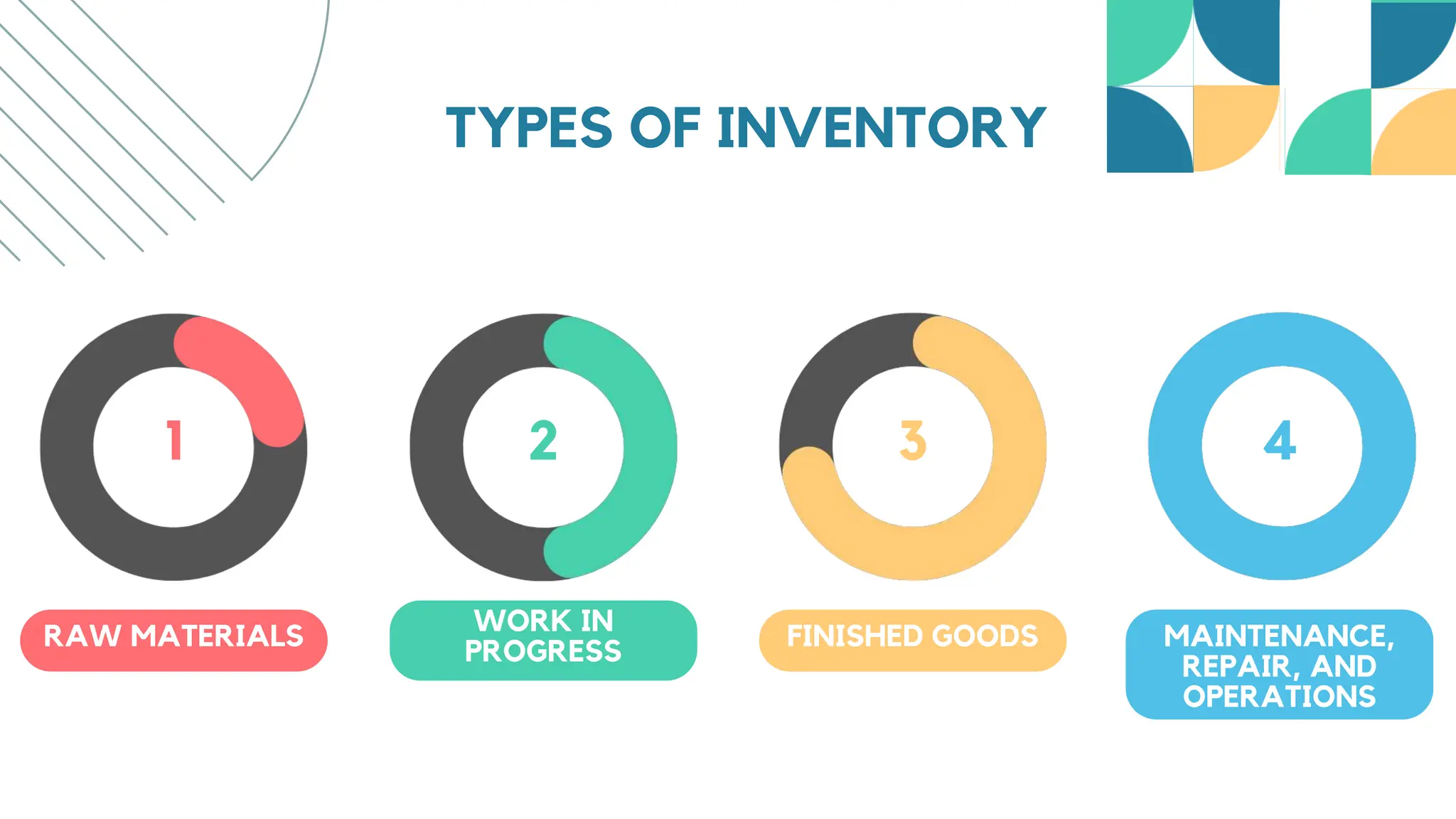

The document discusses inventory management, emphasizing its importance in optimizing resources and meeting customer demands. It covers key strategies, types of inventory, and various control systems, including technology such as RFID and barcode systems. The presentation concludes with a recap of the significance of effective inventory management and an invitation for questions on the topic.