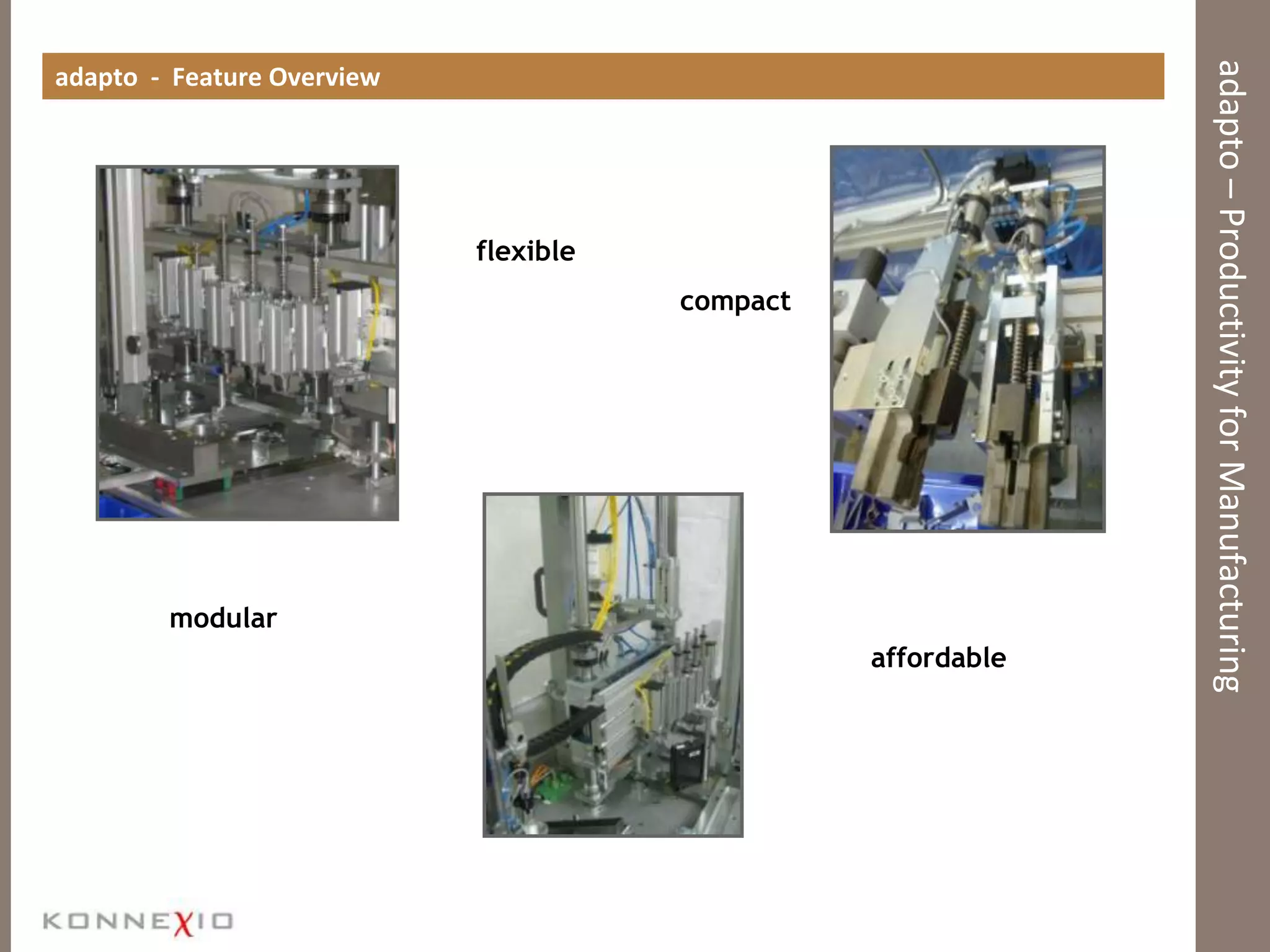

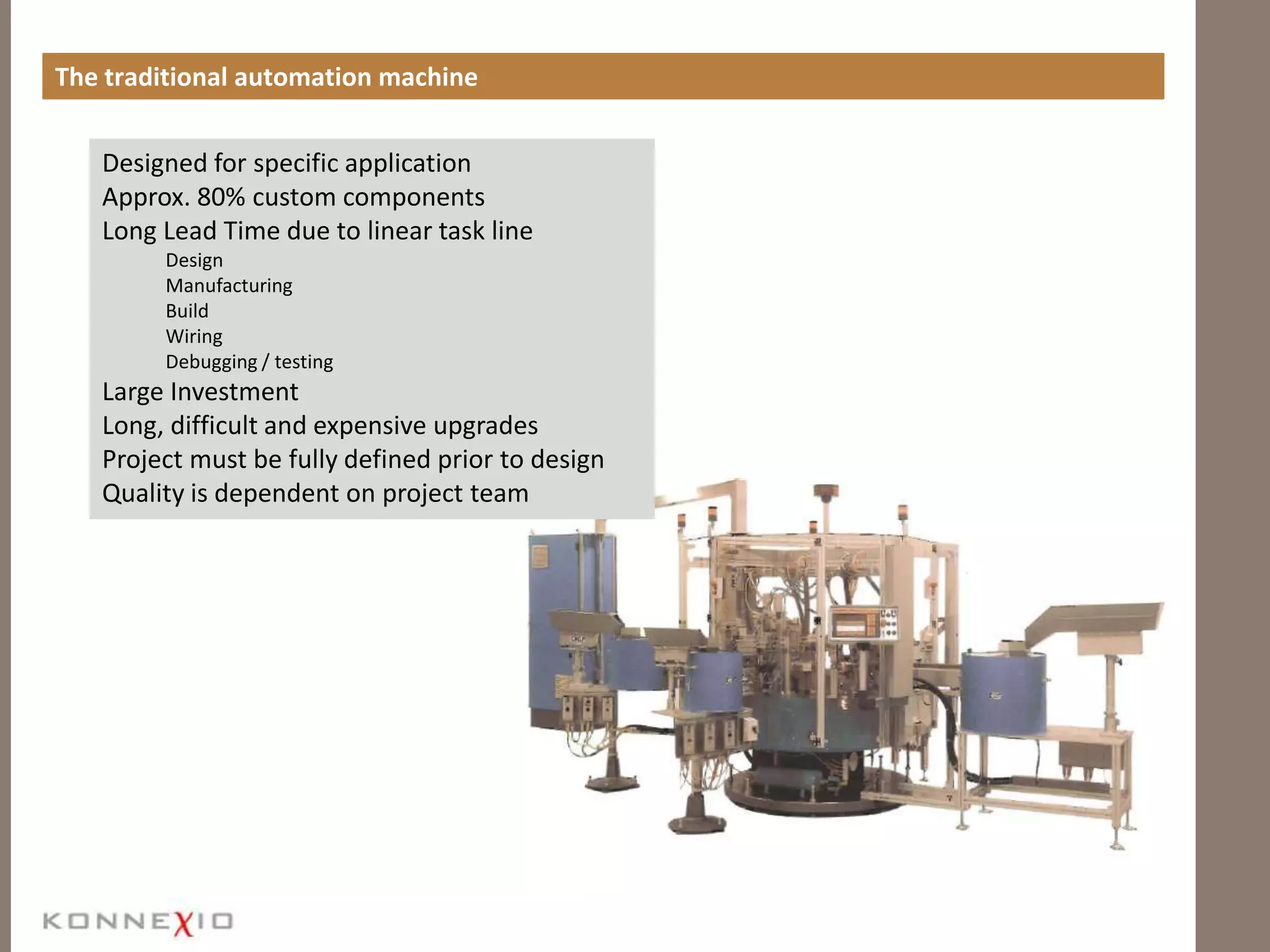

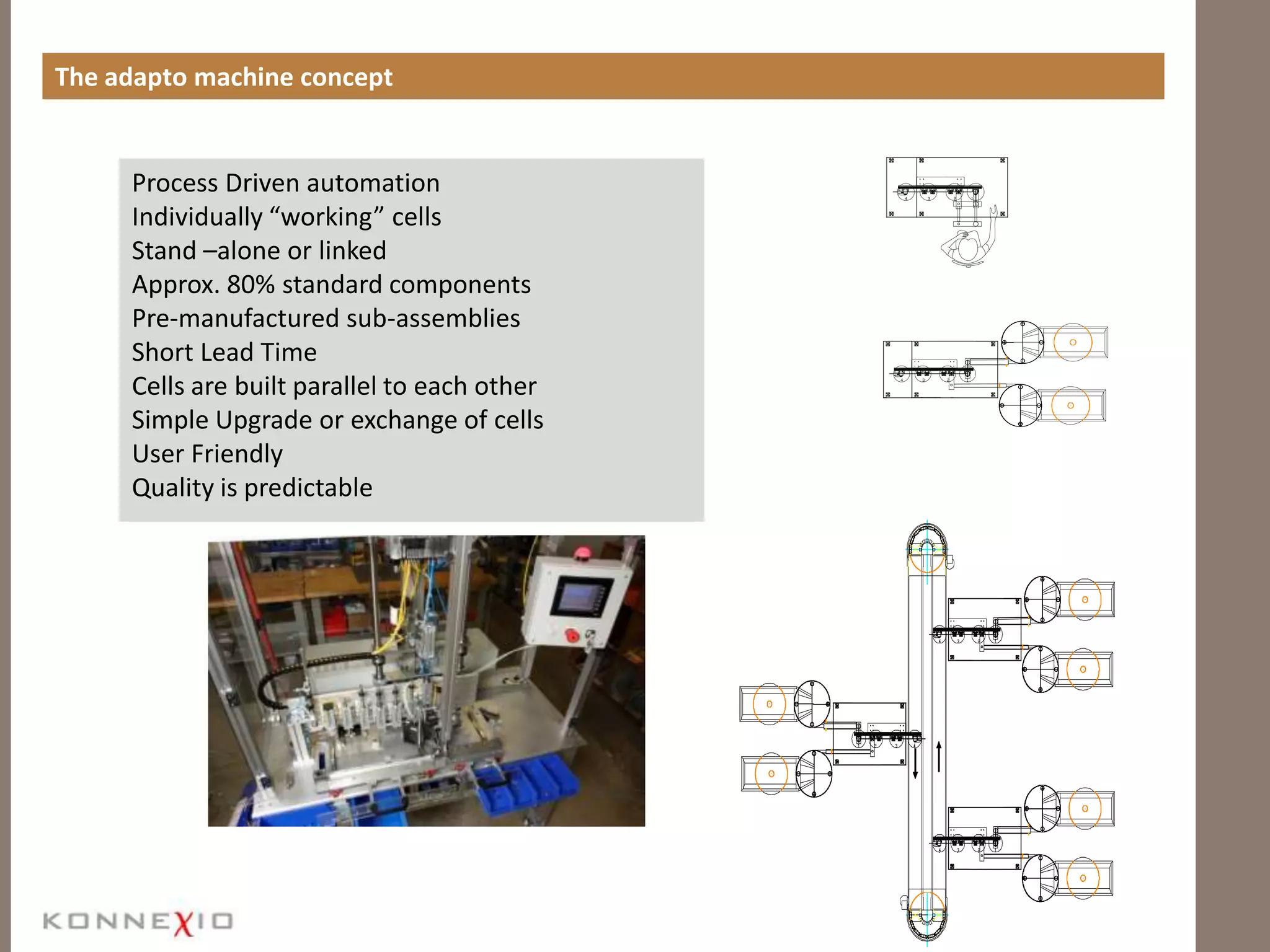

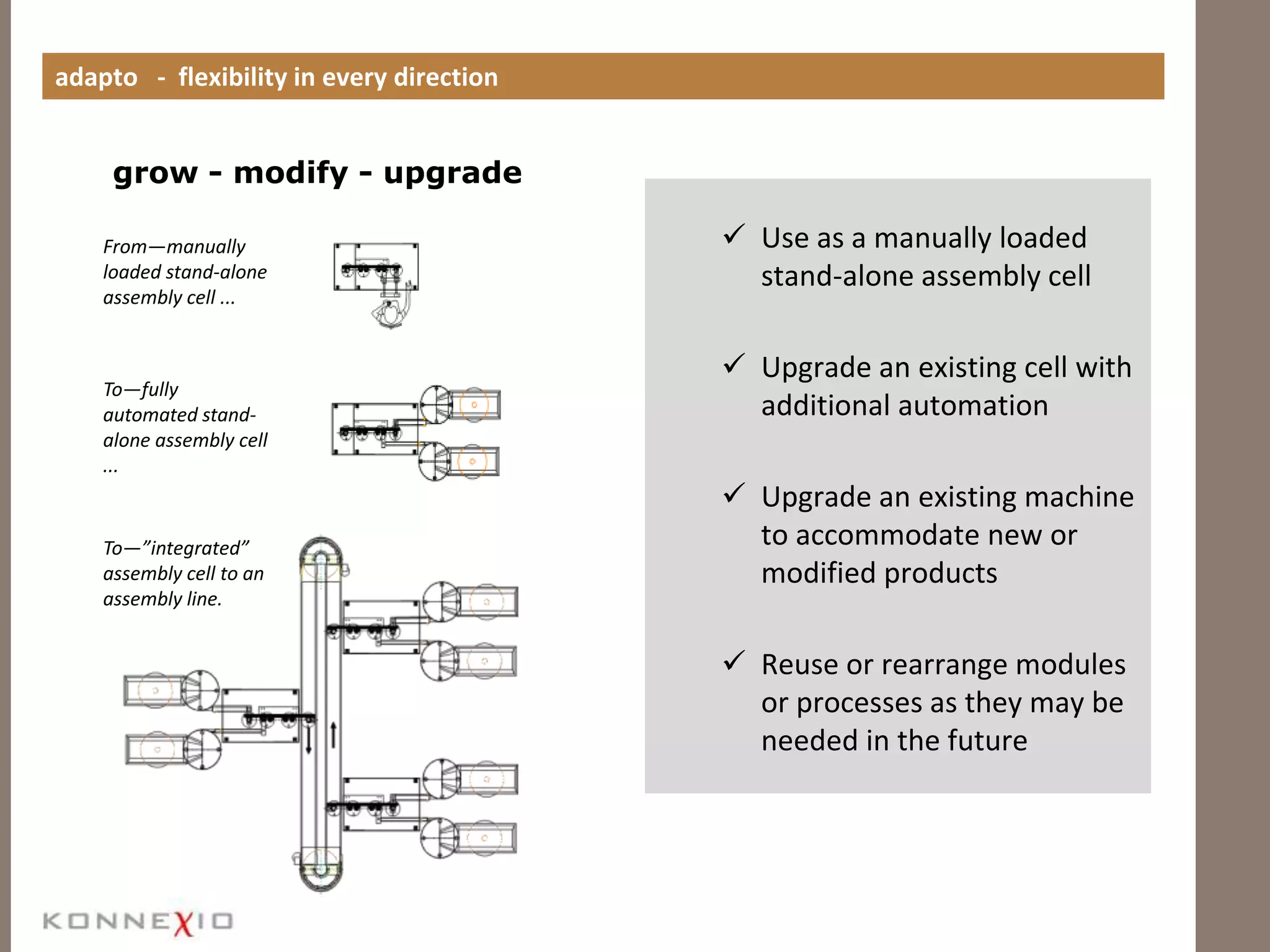

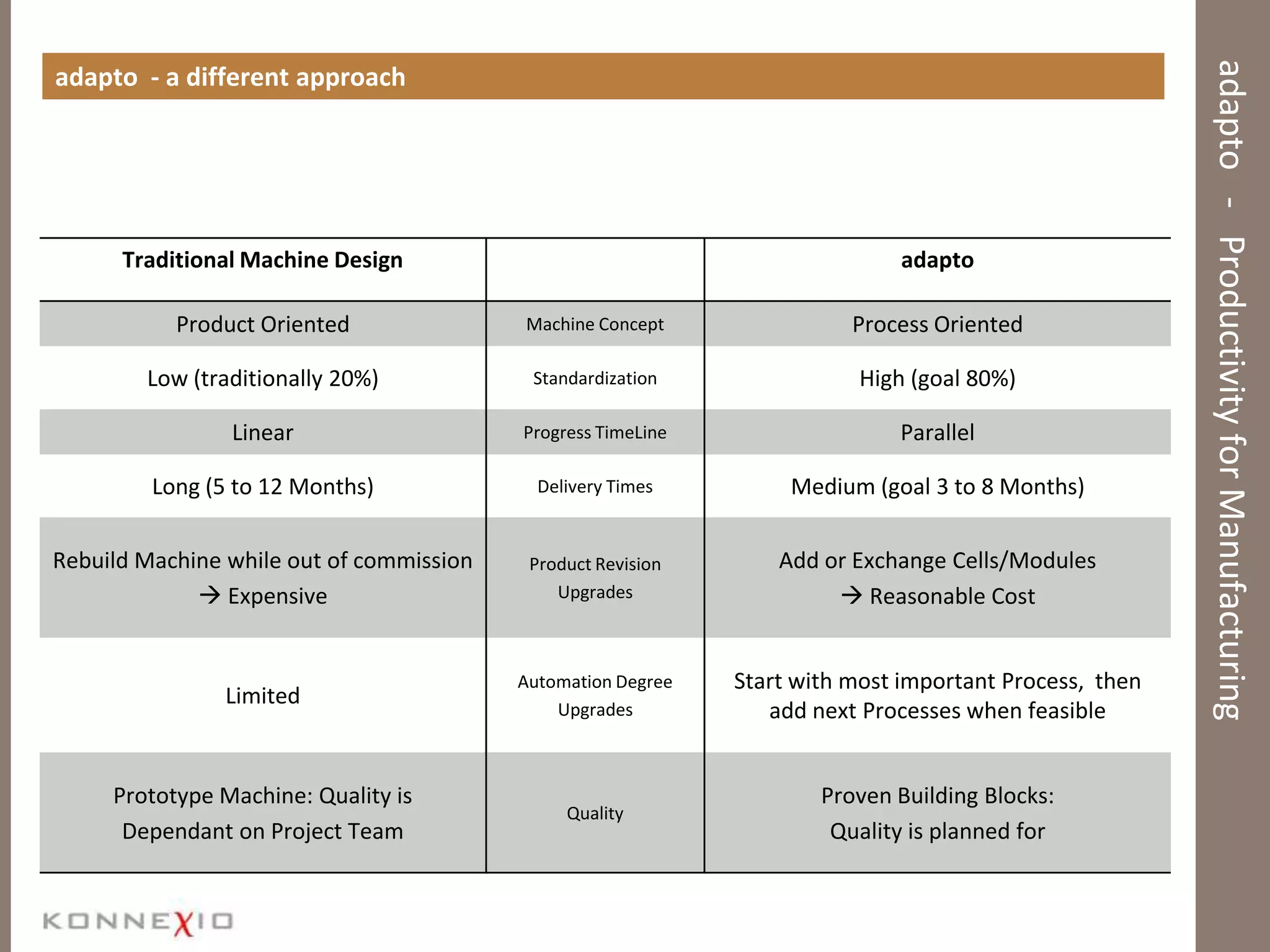

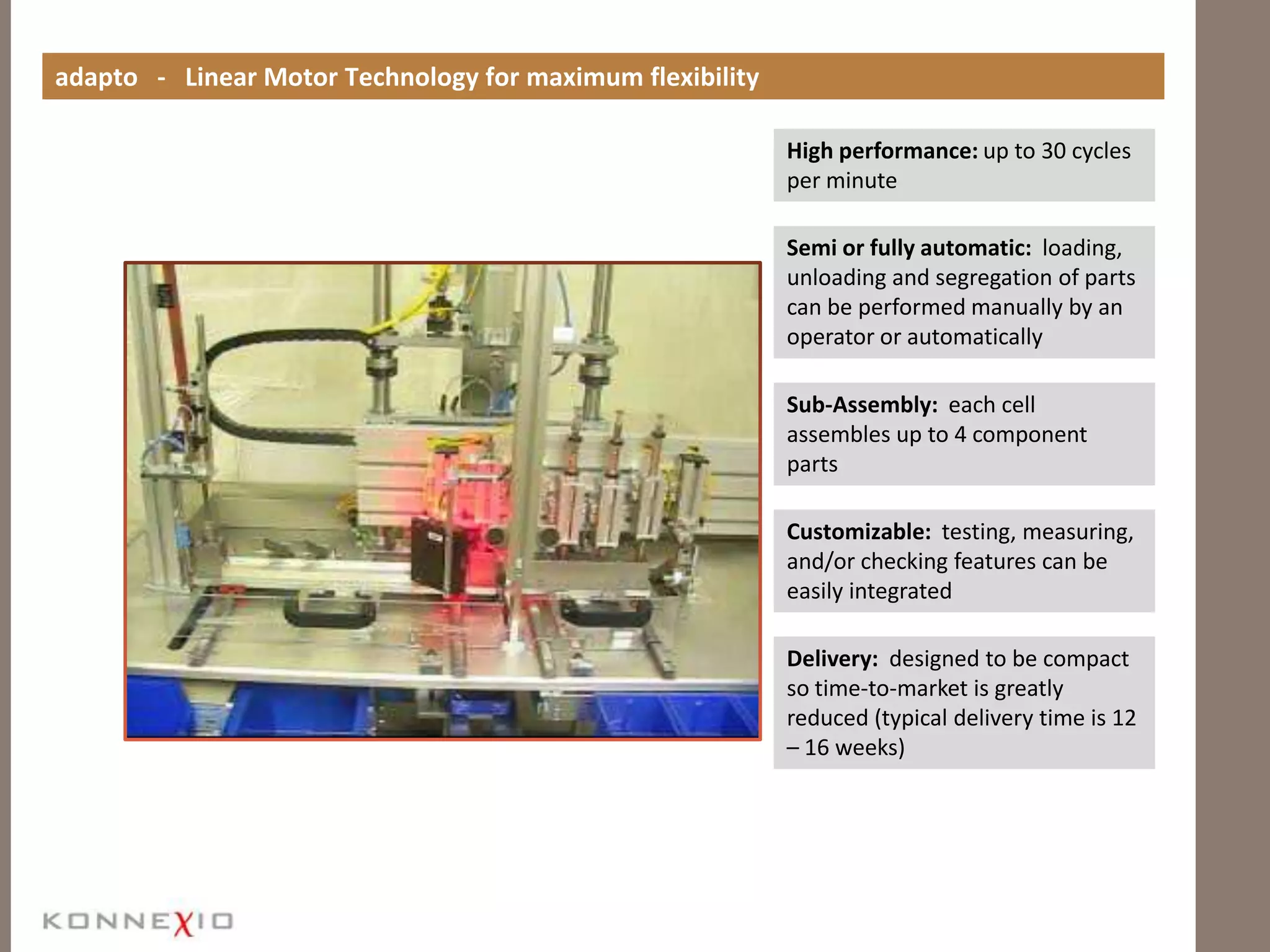

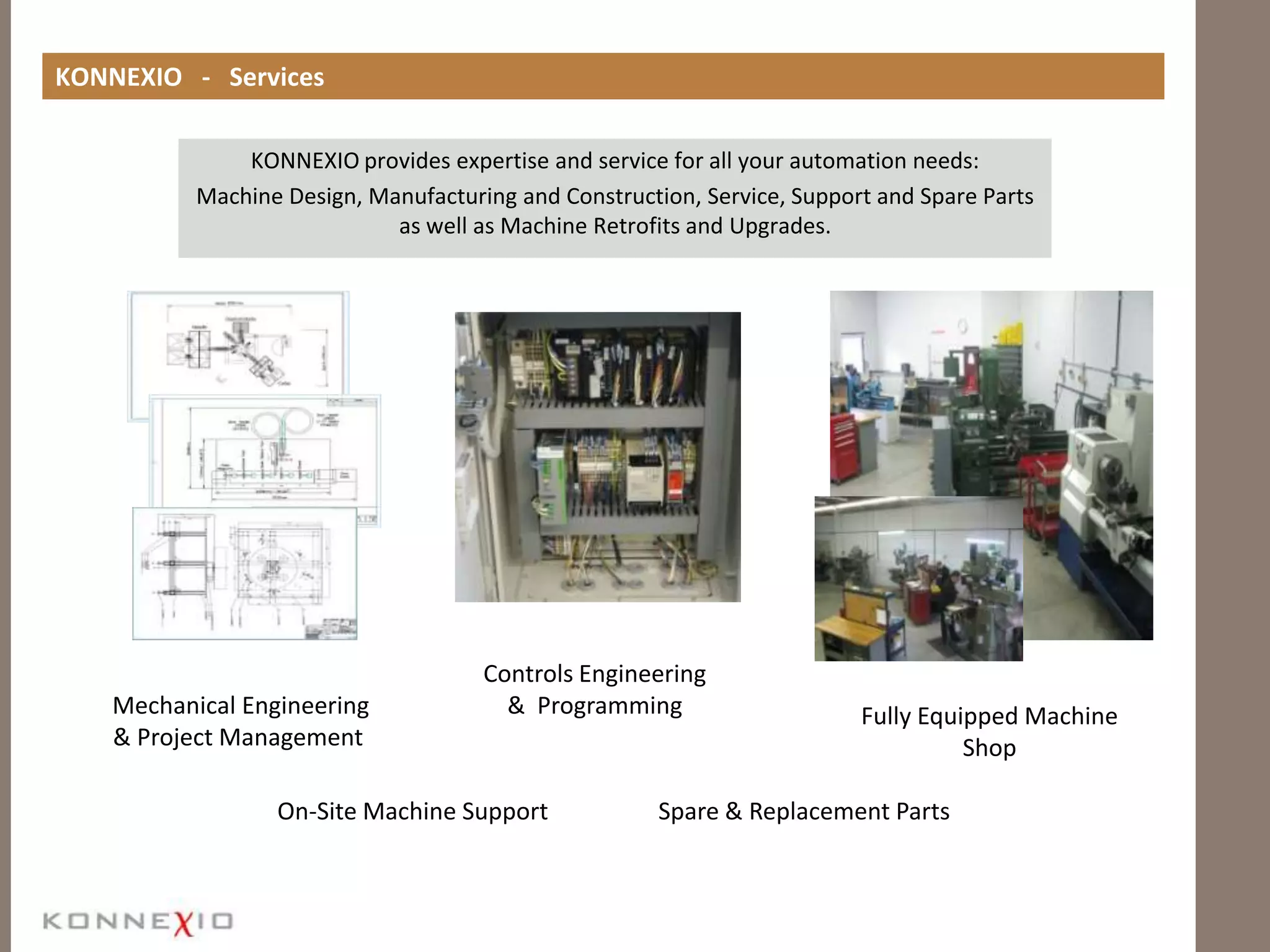

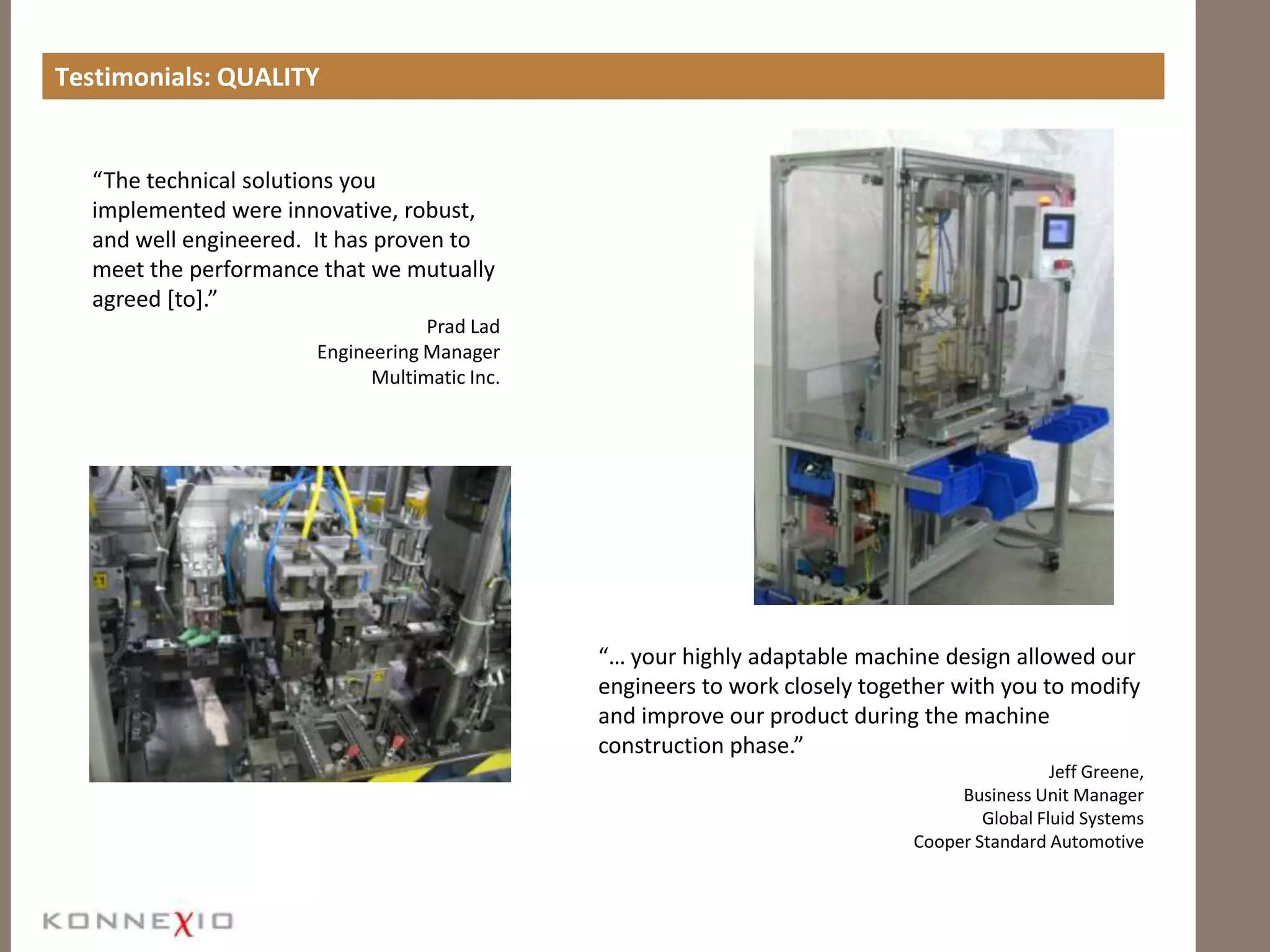

This document discusses adapto, a modular and flexible automation solution for manufacturing. It notes challenges facing manufacturers like short product life cycles. Adapto aims to address this with a system of individually working cells using 80% standard components for quick assembly. This makes adapto affordable and customizable. It can grow from manual to fully automated. Konnexio provides expertise in machine design, manufacturing, and service to support adapto automation needs. Testimonials praise adapto's technical solutions, ability to modify during construction, and reliability in meeting deadlines.