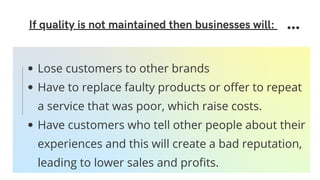

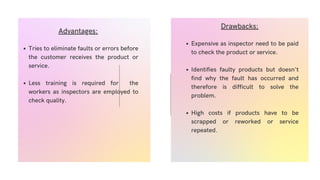

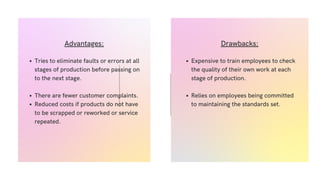

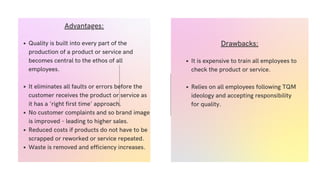

This document discusses quality, quality control, quality assurance, and total quality management. It explains that quality means meeting customer expectations. Quality control checks quality after production through inspectors, while quality assurance checks quality throughout production by employees. Total quality management focuses on continuous quality improvement by building quality into every stage and making all employees responsible for quality. Maintaining quality helps businesses through increased sales, customer loyalty and reputation while lack of quality hurts businesses.