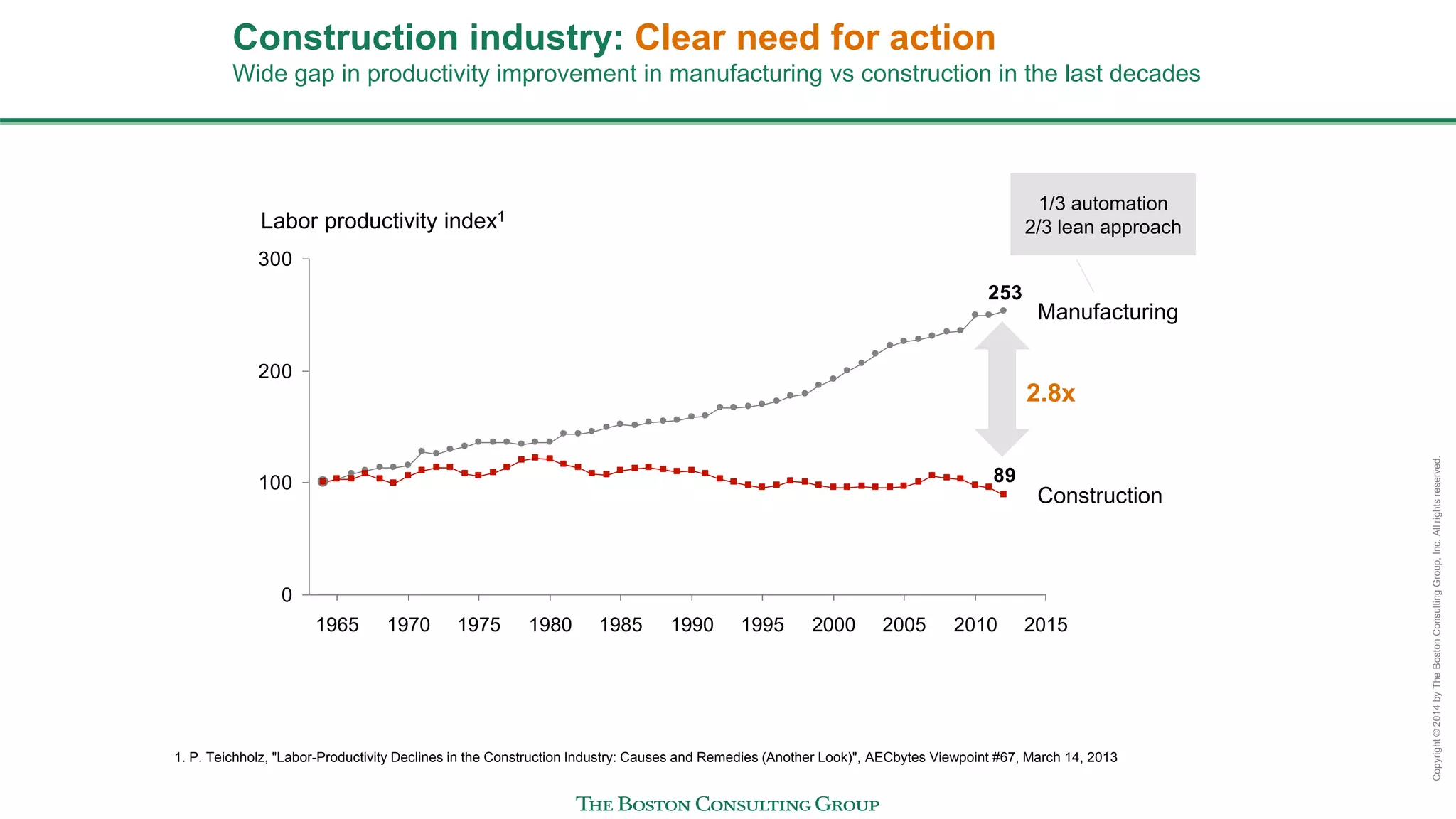

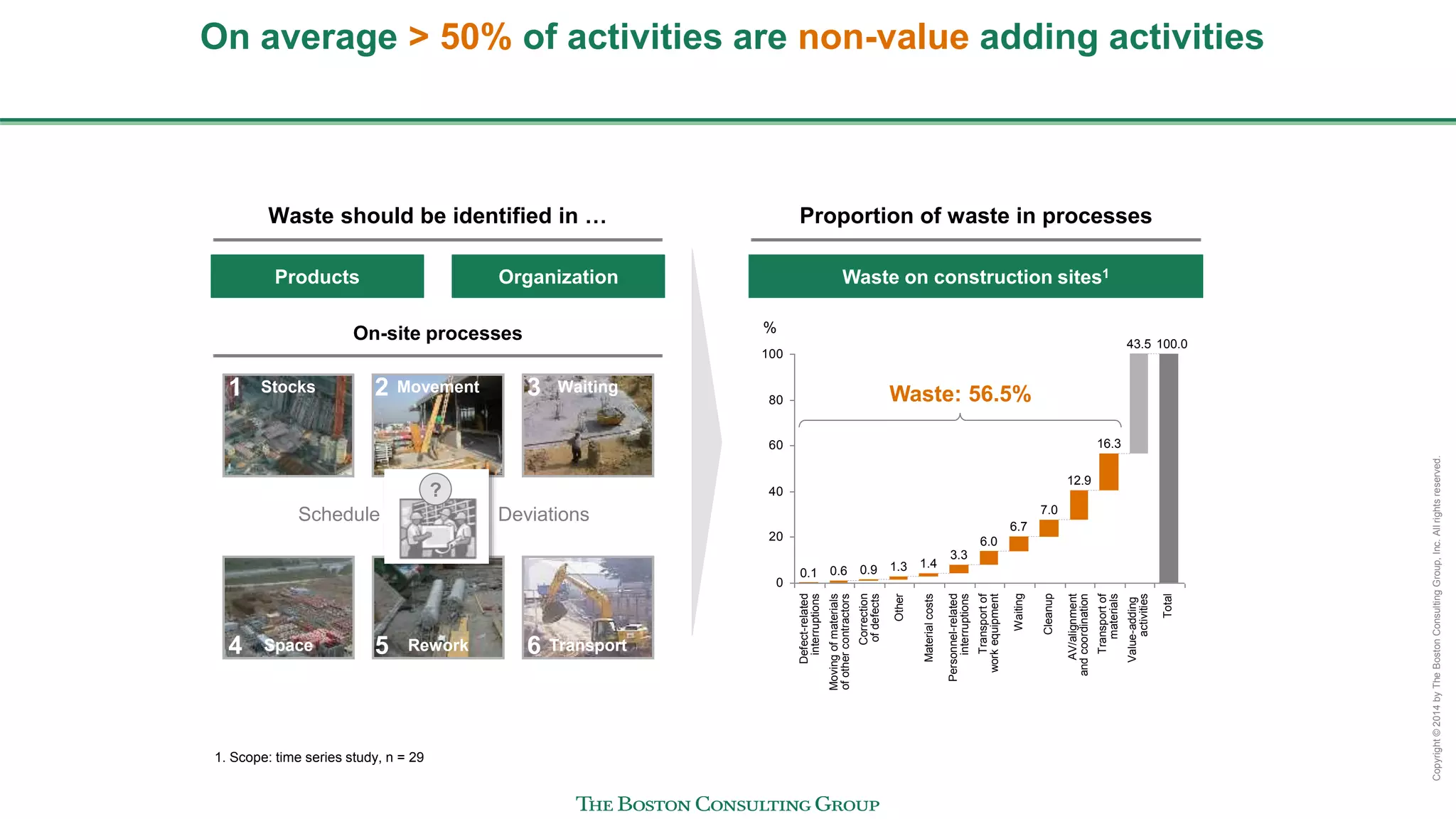

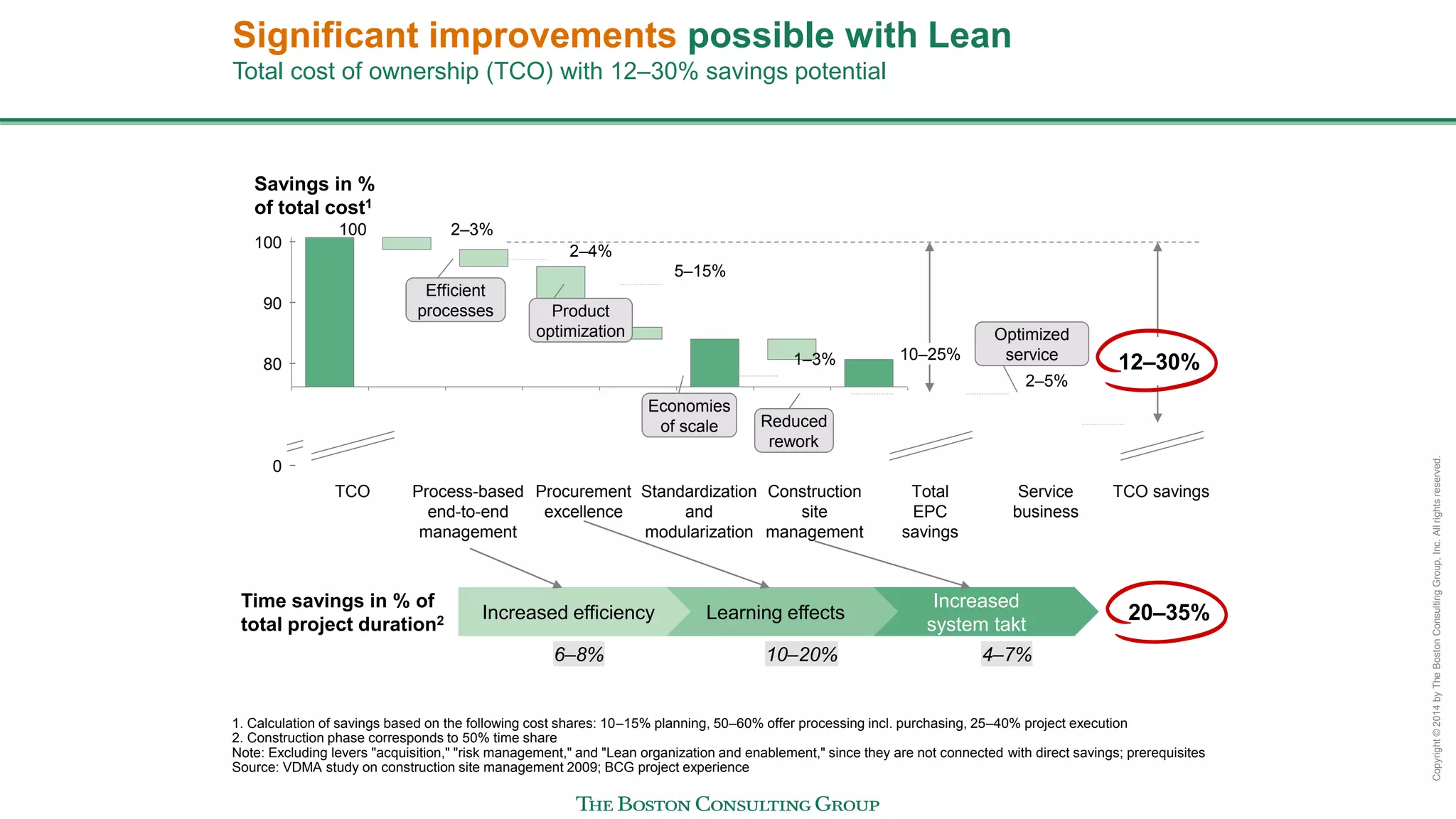

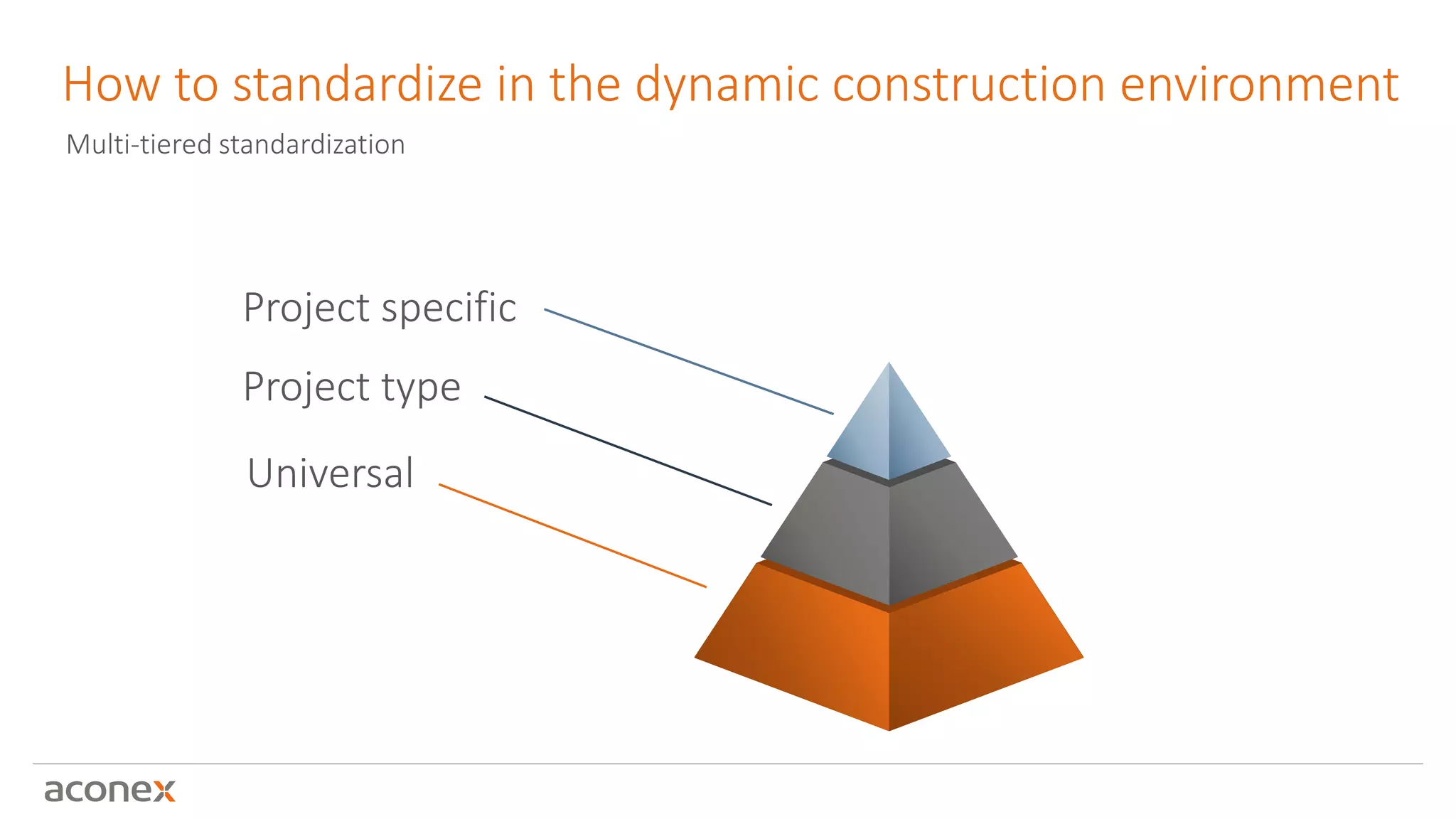

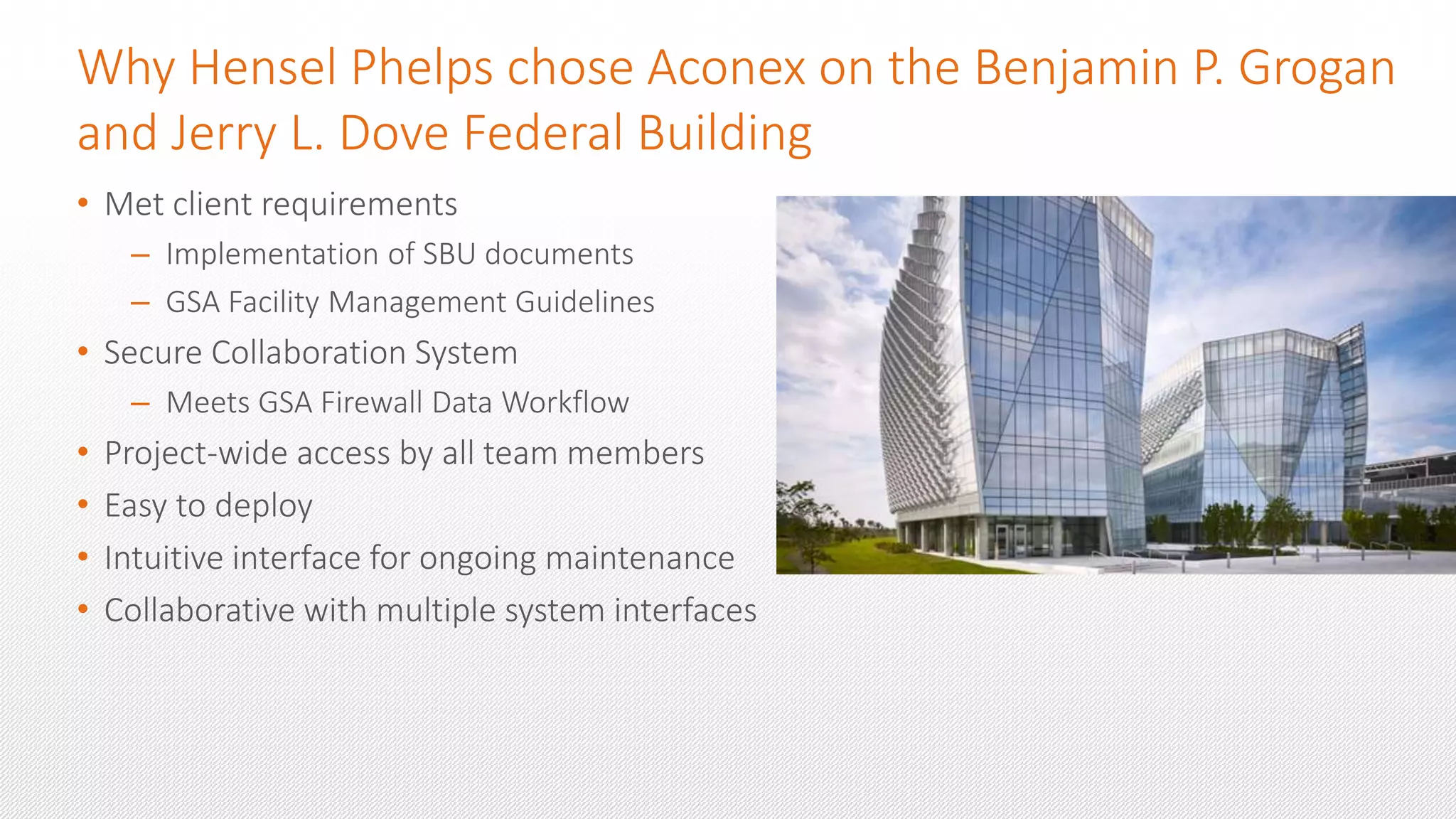

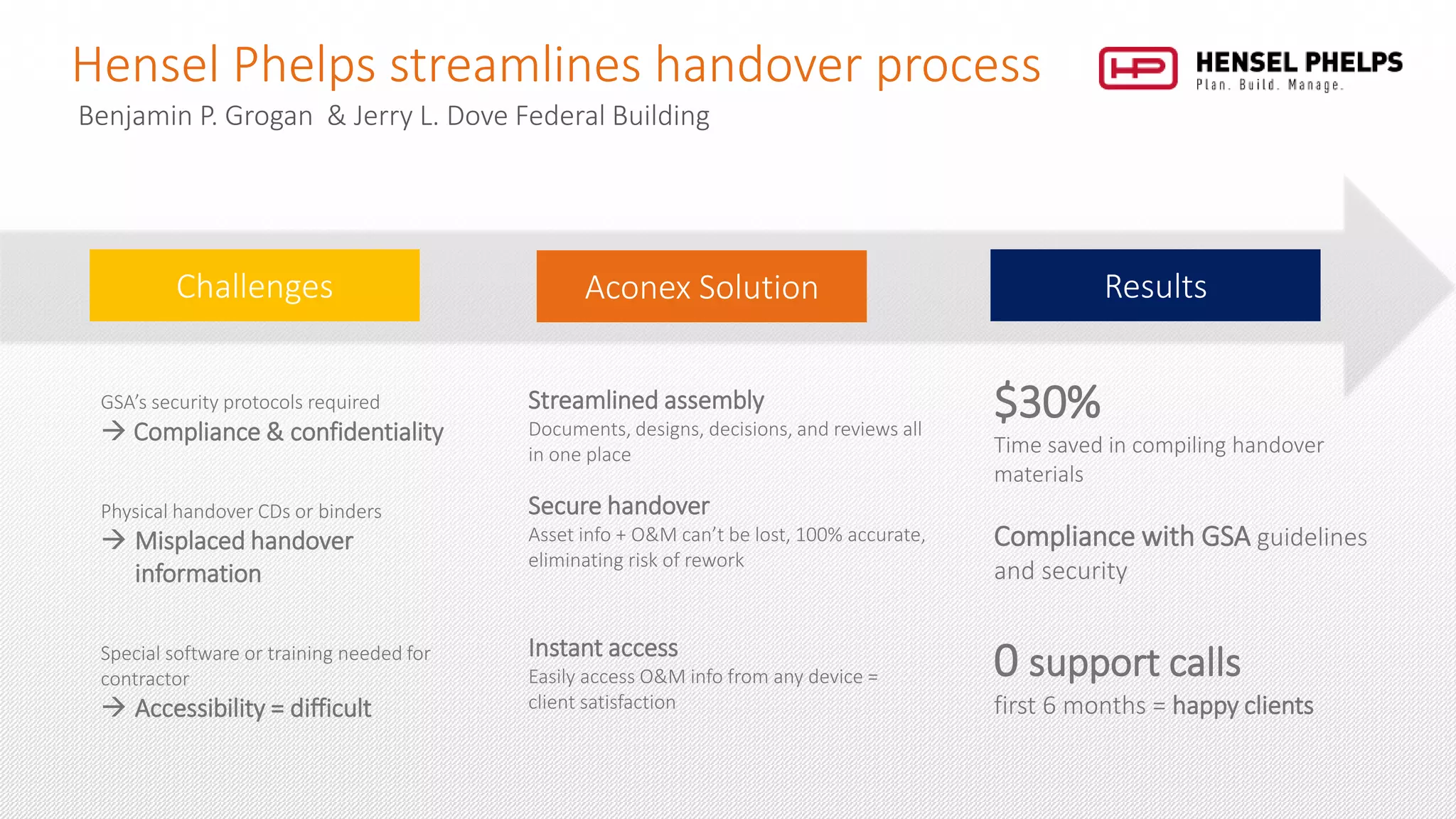

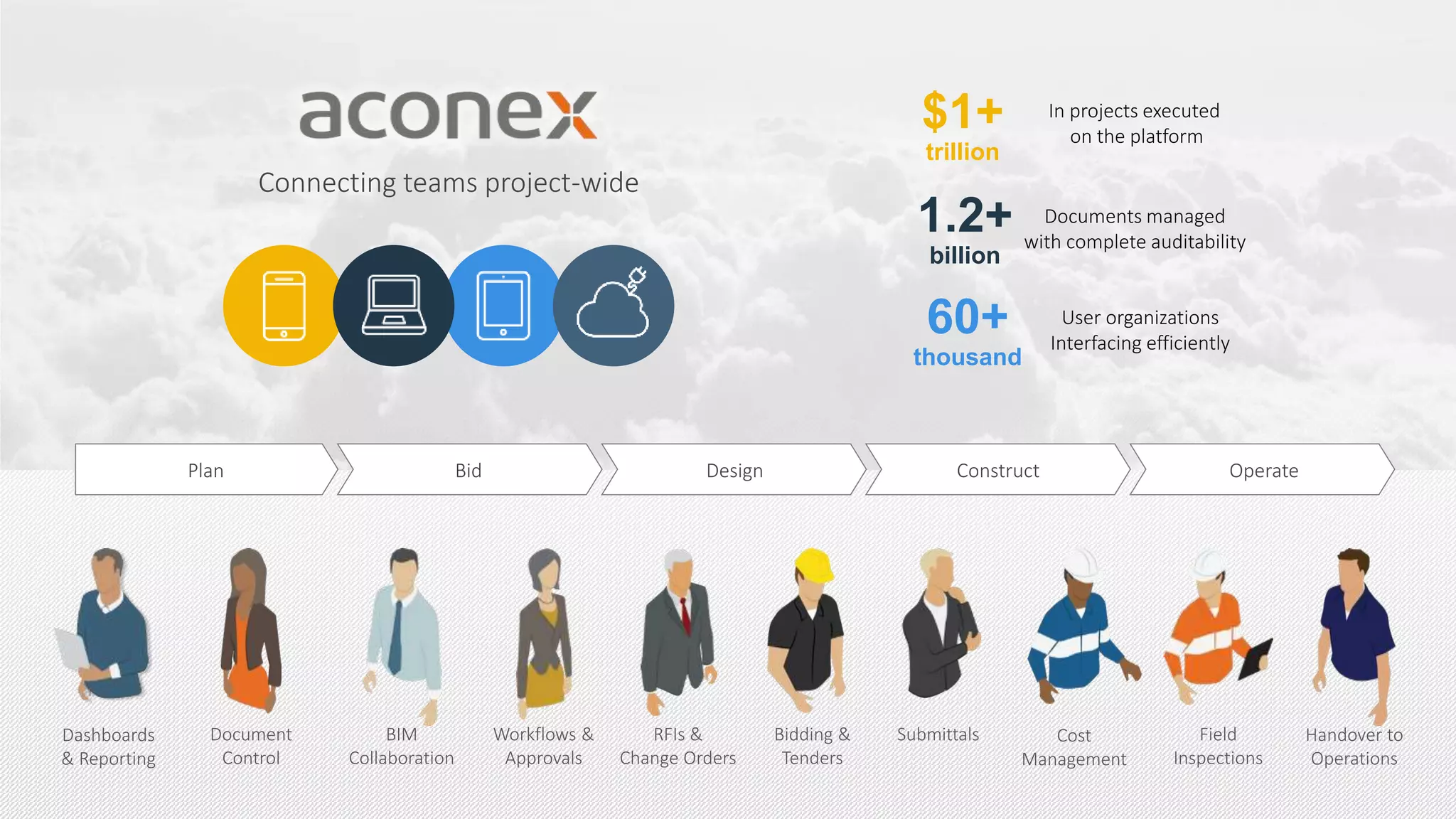

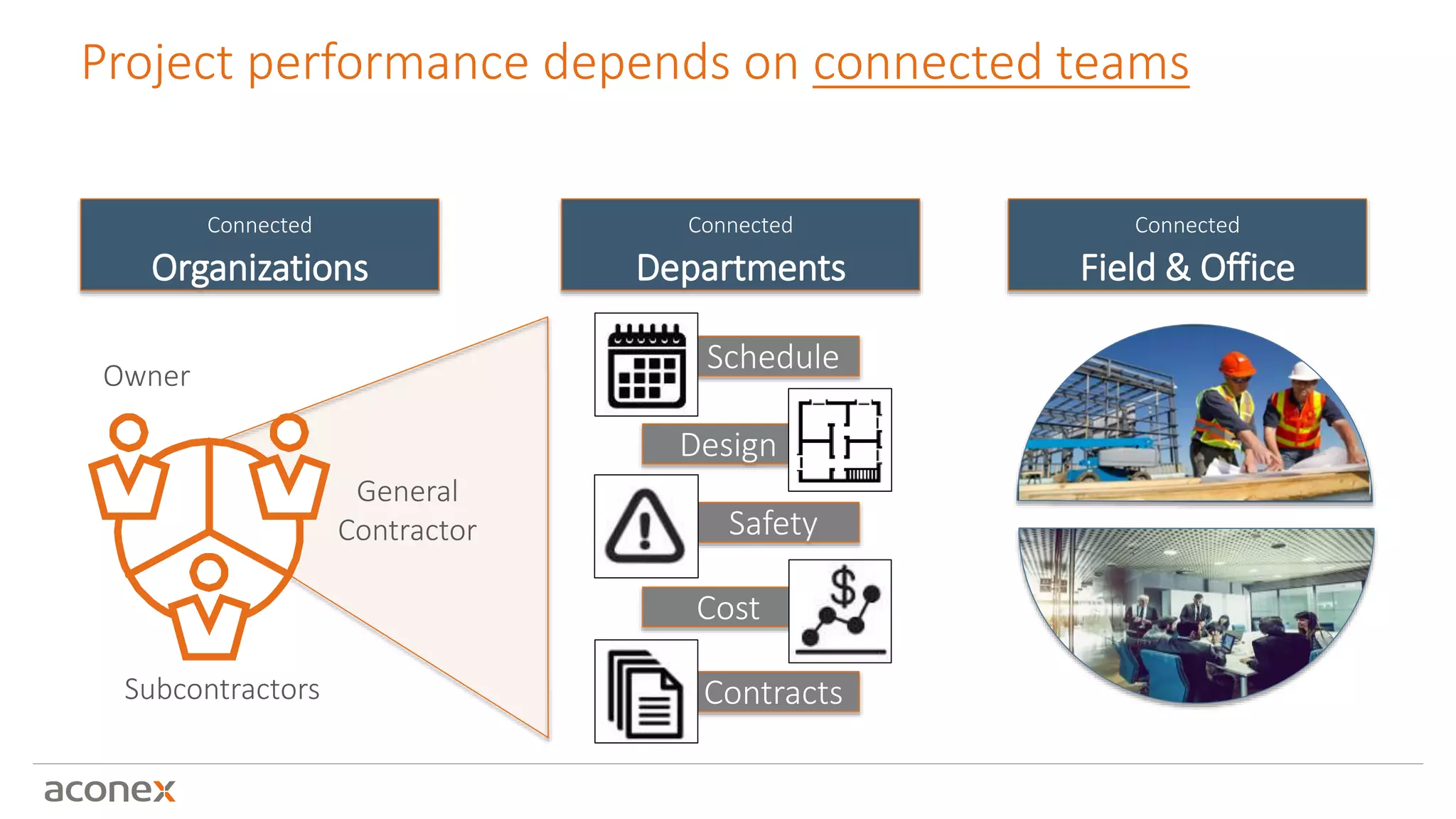

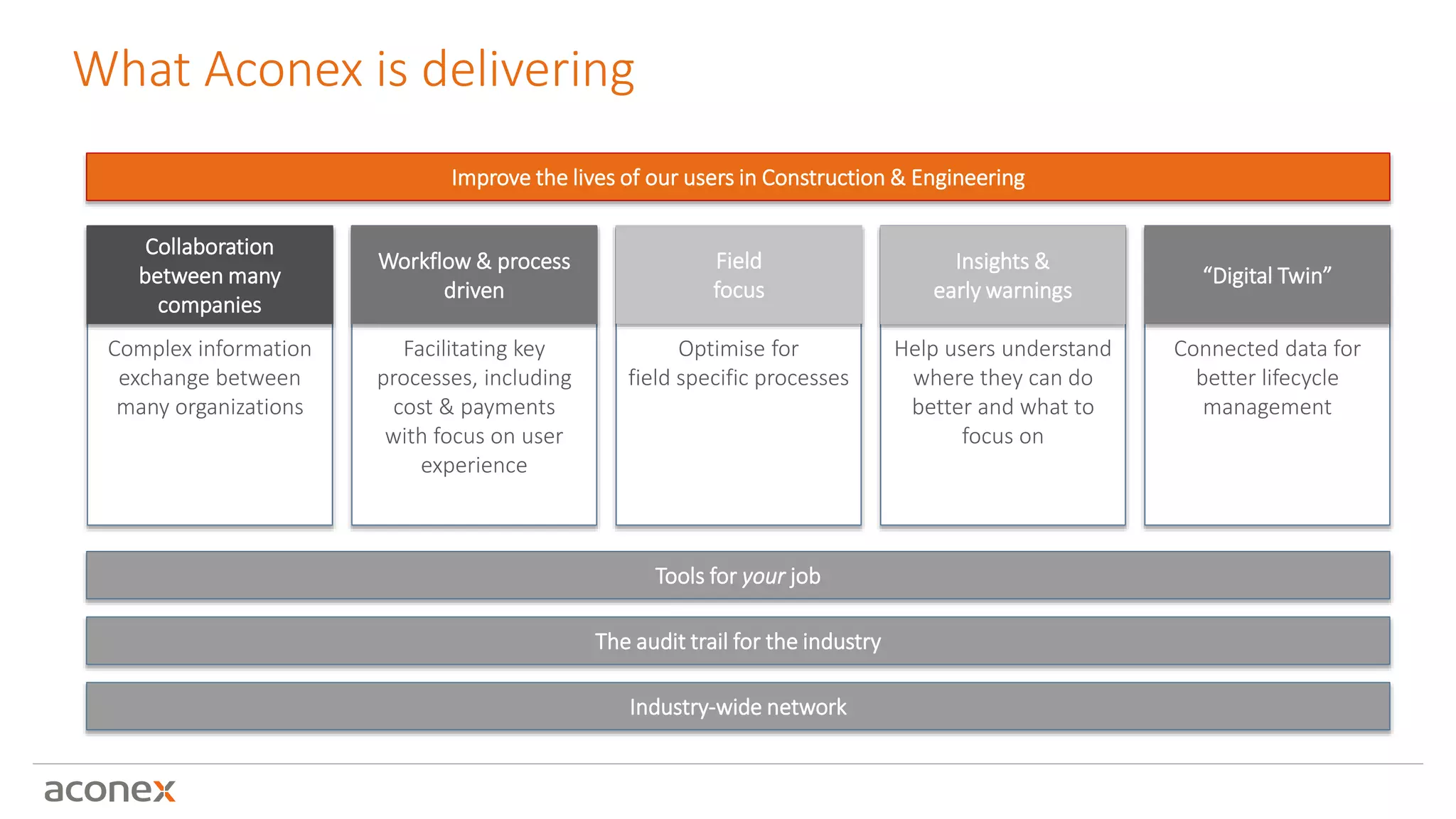

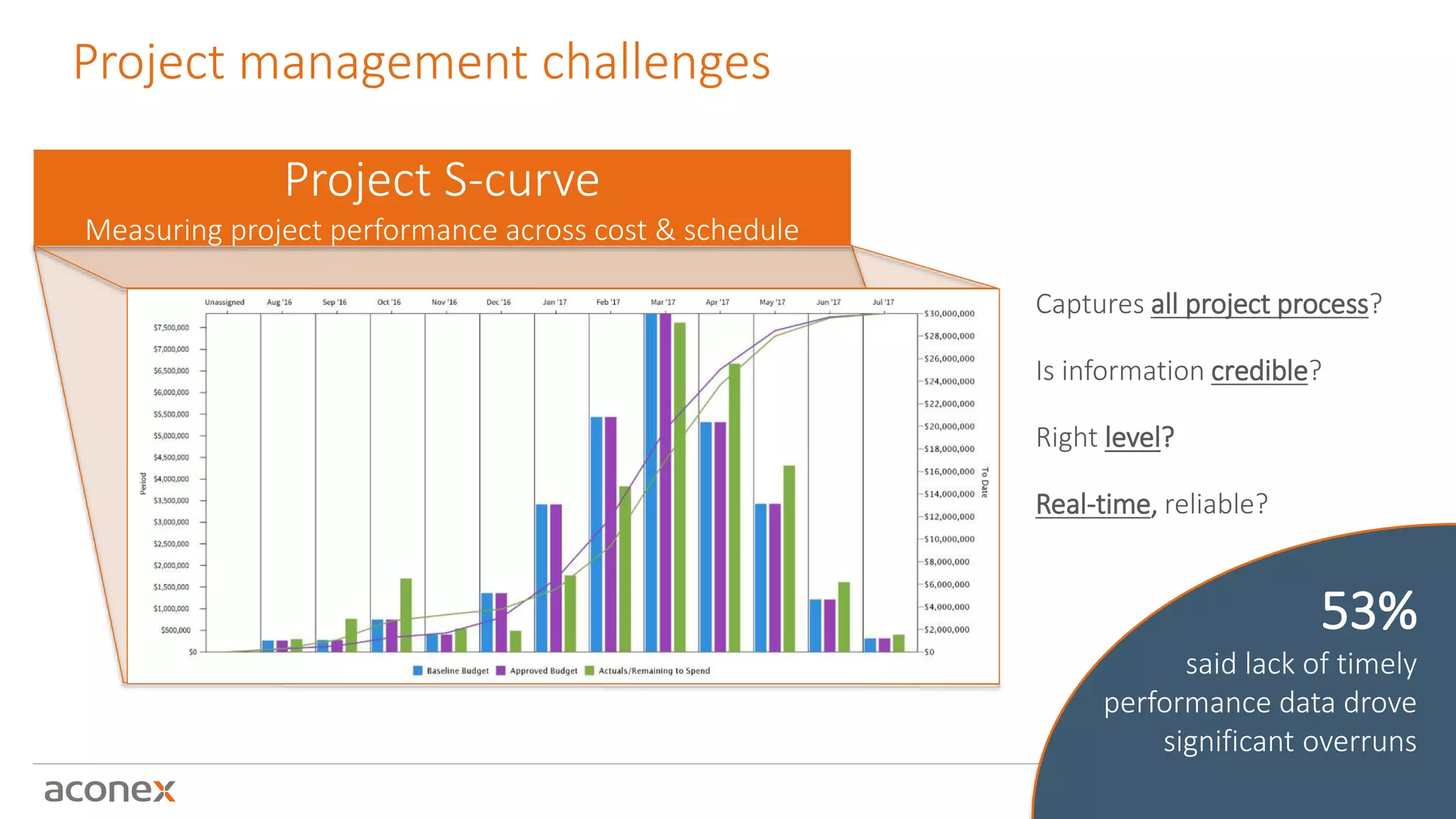

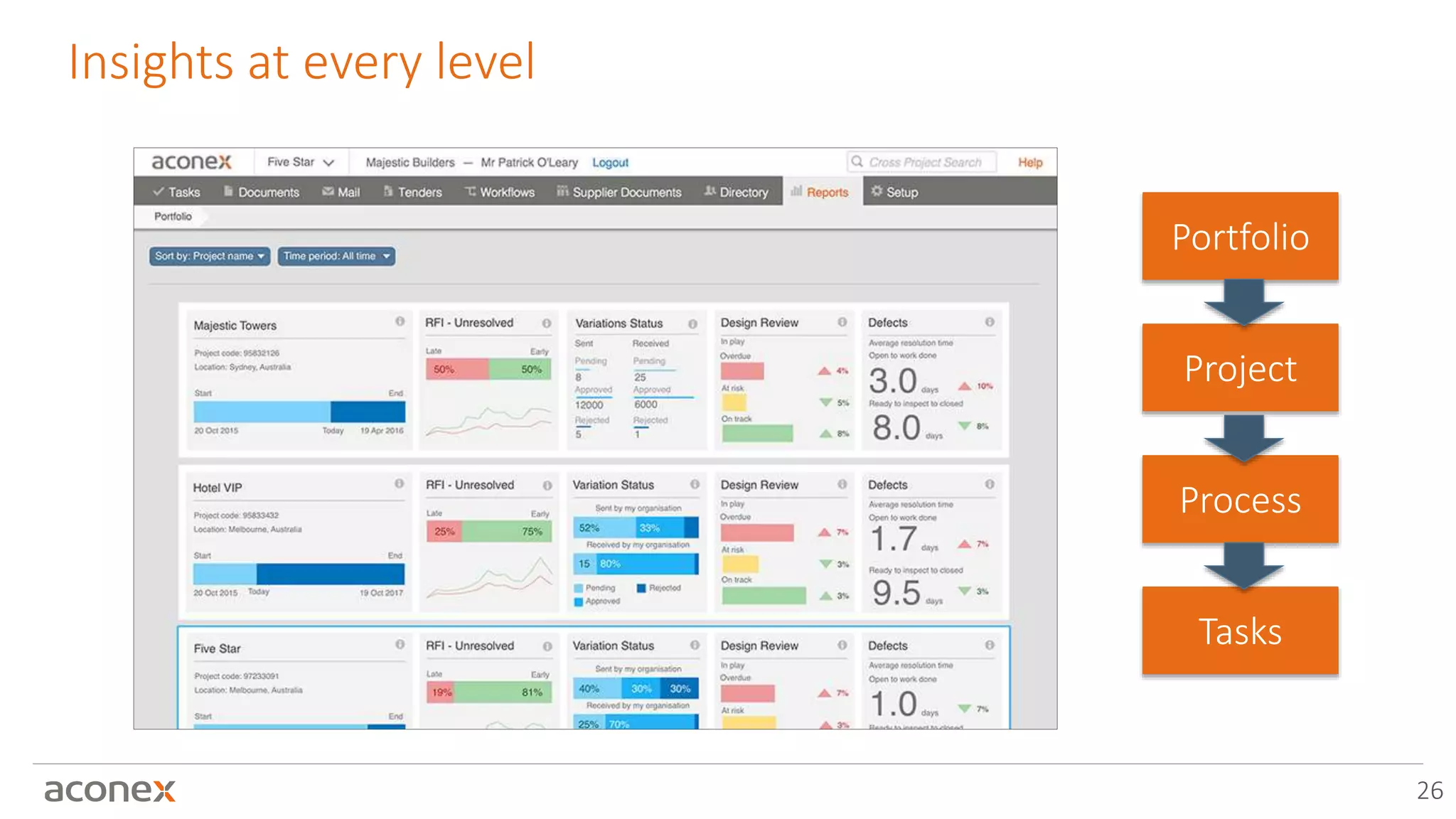

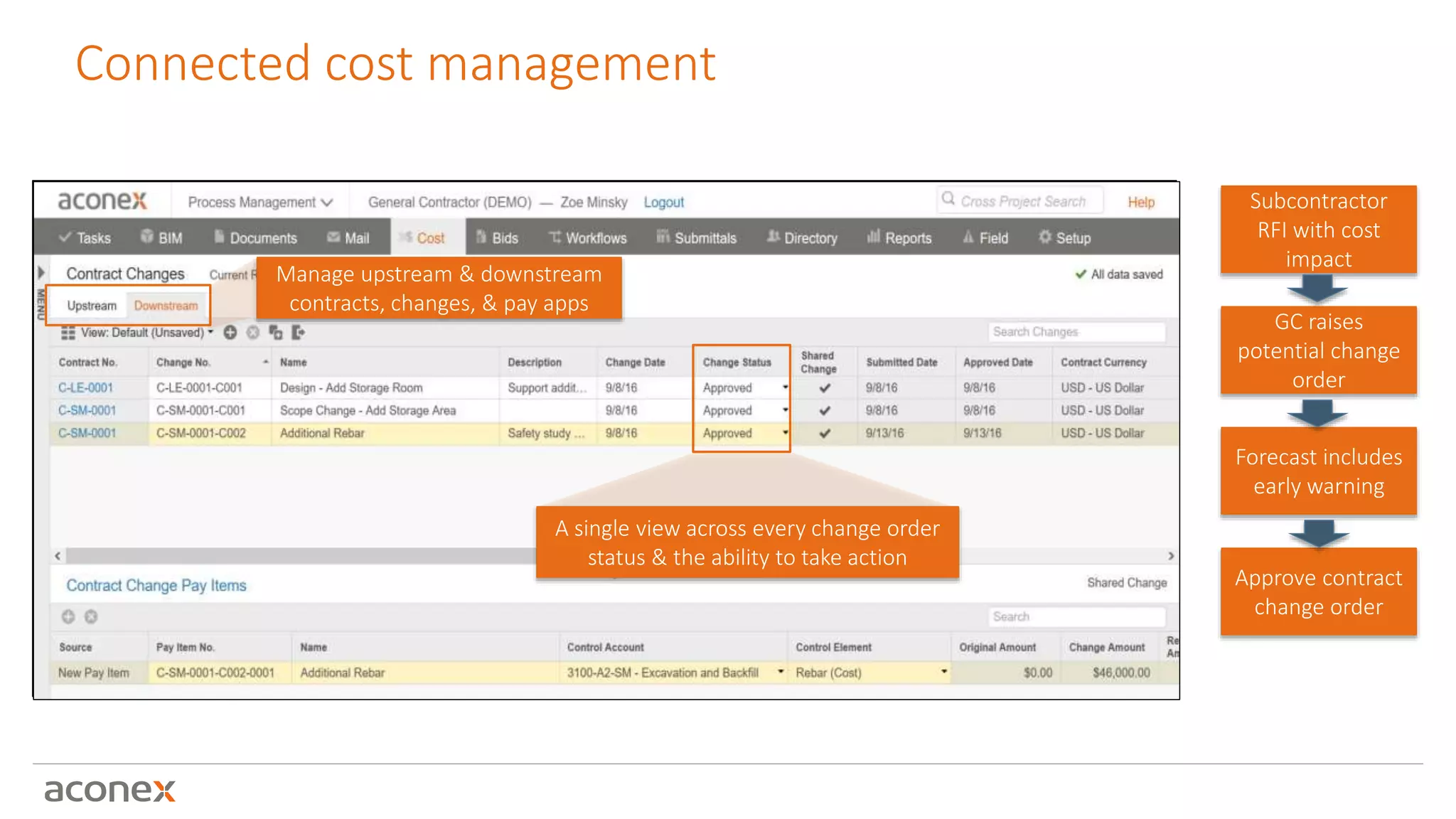

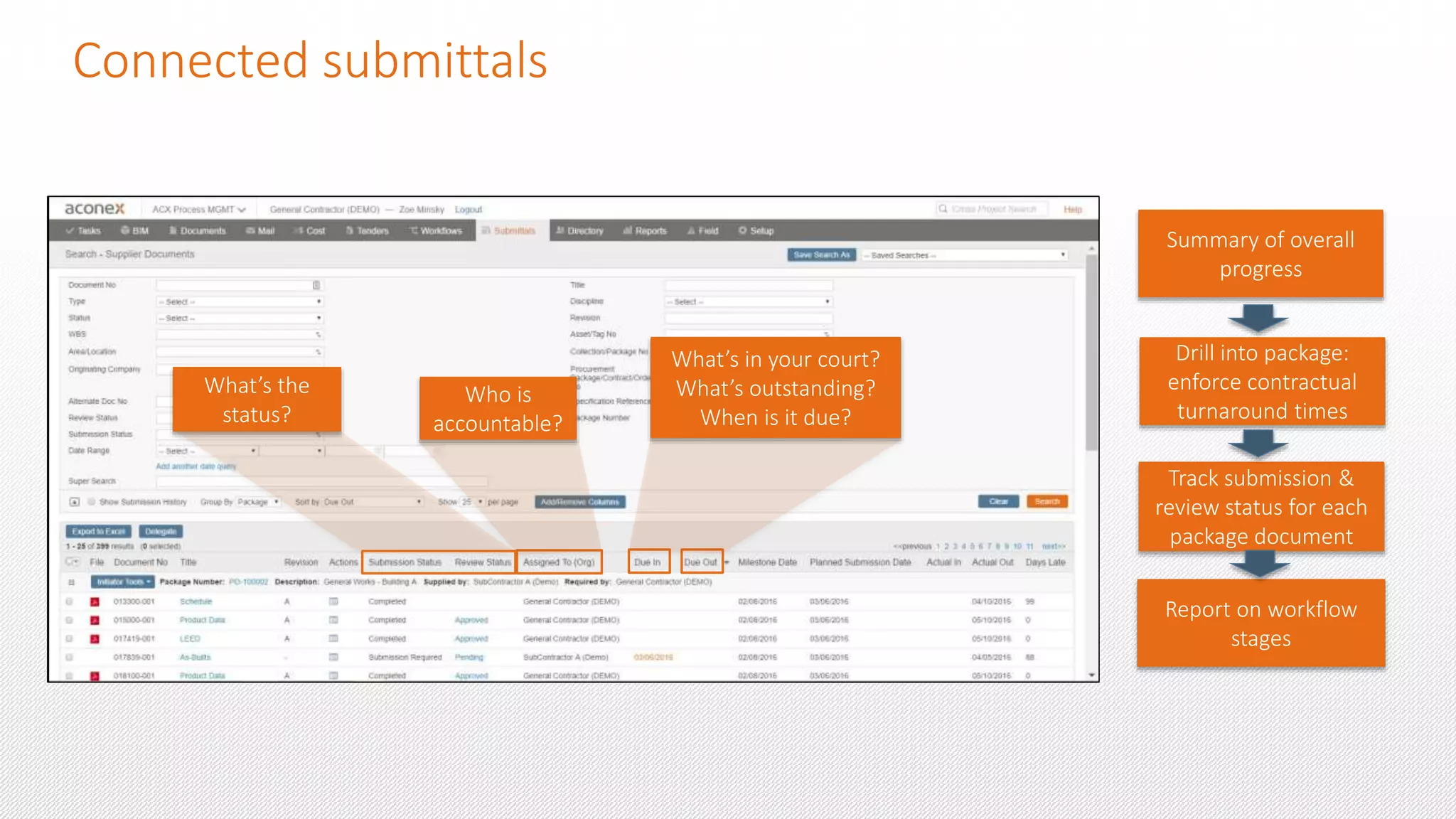

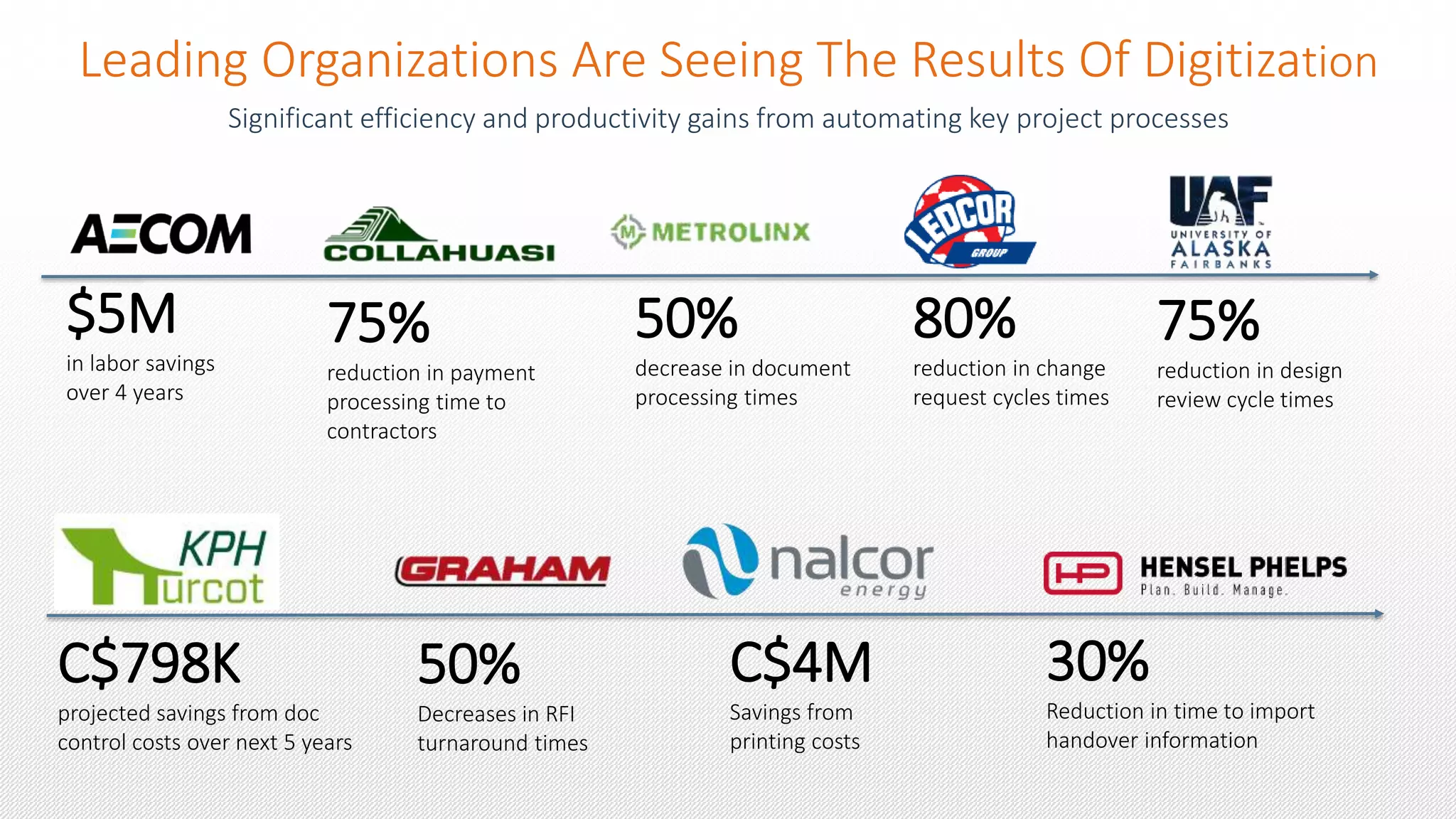

The document discusses the urgent need for innovation in the construction industry to address significant productivity gaps compared to manufacturing. It highlights the potential for substantial efficiency gains through standardized processes, automation, and collaborative technologies, specifically mentioning Aconex as a solution for improving project management and document control. Key performance metrics indicate substantial time and cost savings achieved by leading organizations through digitization and process optimization.