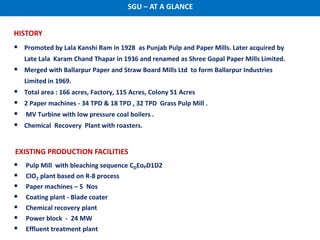

SGU is a paper mill located in Ballarpur, India with an annual capacity of 82,000 tonnes of paper. It has ISO 9001:2008, ISO 14001:2004, FSC, and OHSAS 18001:2007 certifications. The mill operates two paper machines, a pulp mill, chemical recovery plant, and power block. It produces various grades of paper including bond, printing, coated, and retail products.