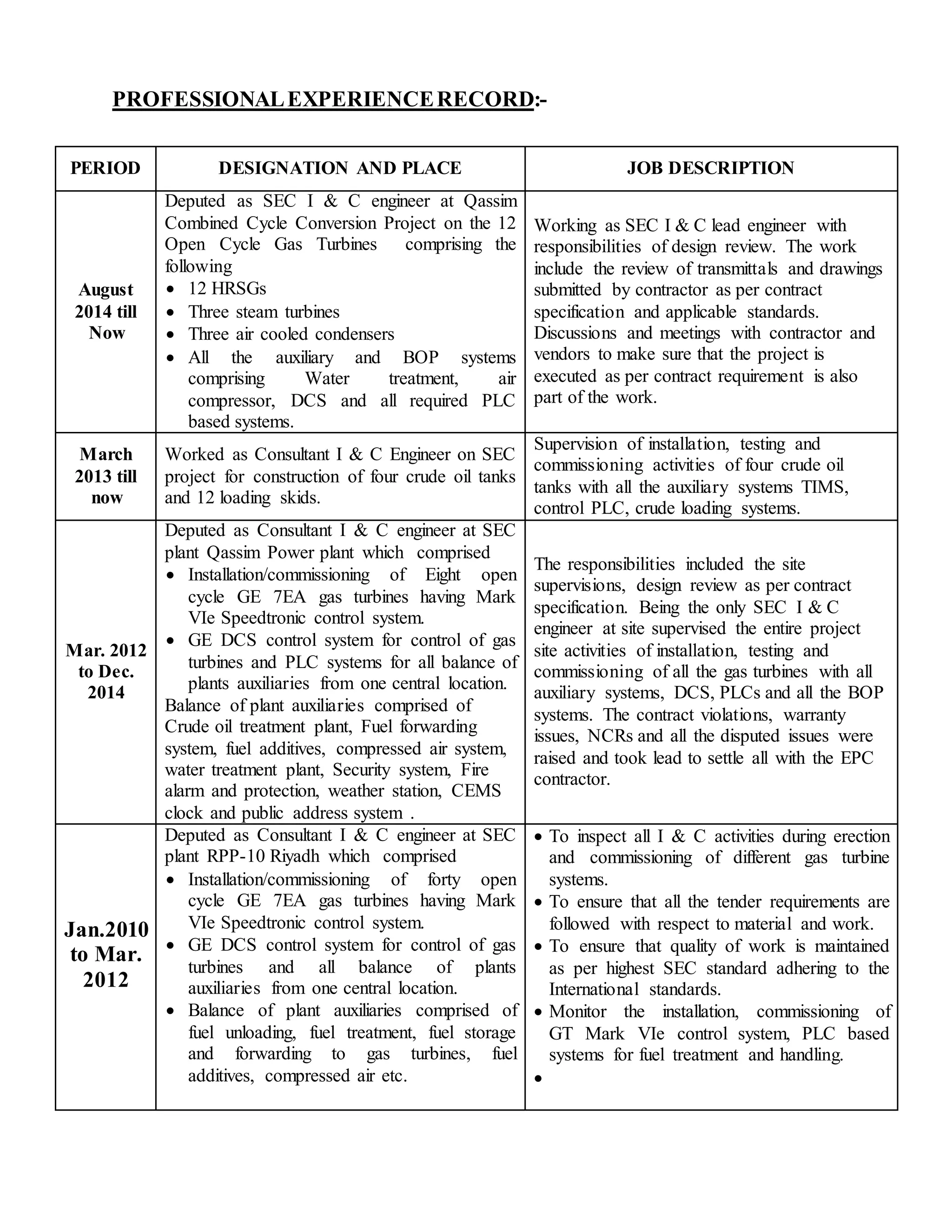

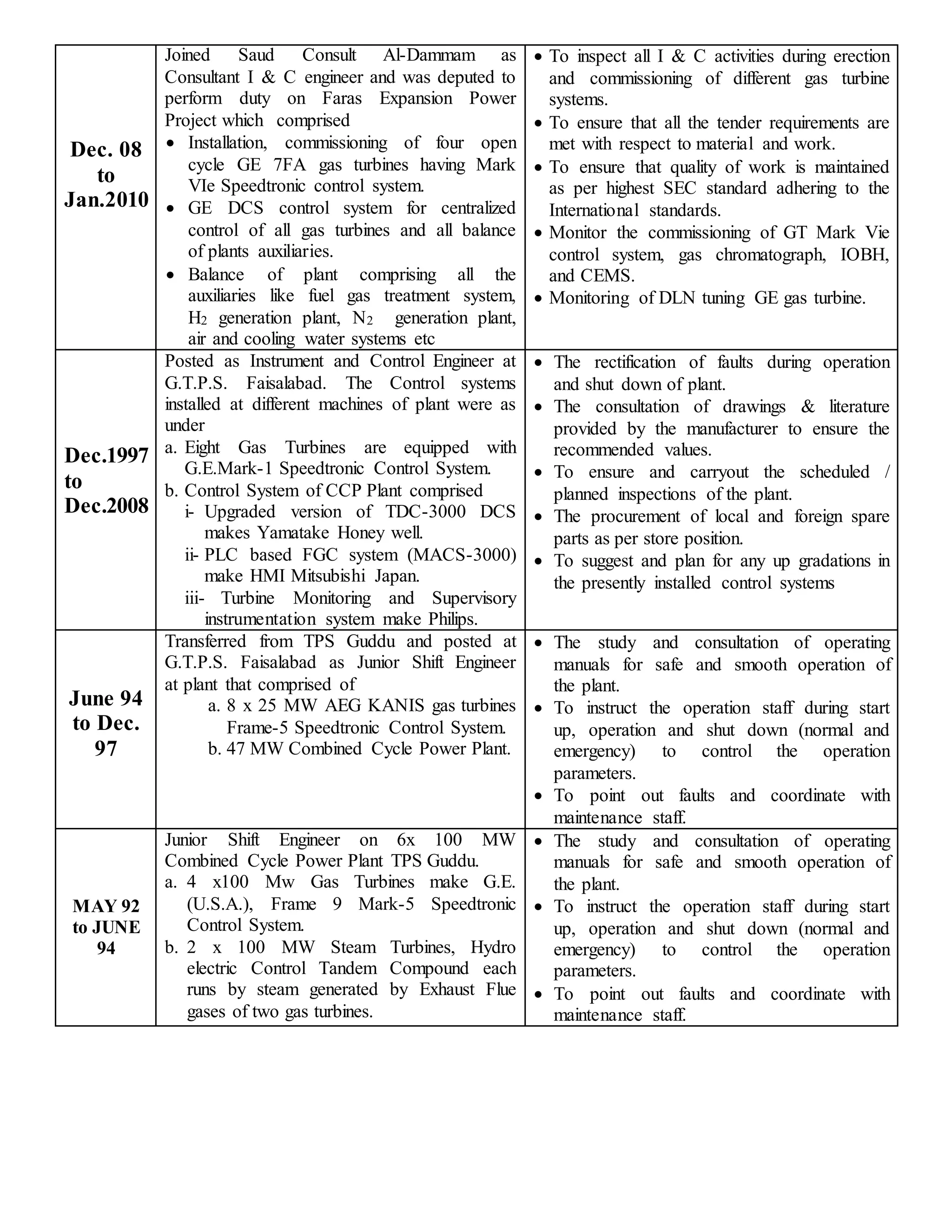

This curriculum vitae is for Engineer Abid Ali. He has 24 years of experience working in instrumentation and control engineering for power plants in Saudi Arabia. Currently he works as a consultant instrumentation and control engineer at a combined cycle power plant in Qassim, Saudi Arabia, where he is responsible for design review and ensuring contract compliance. He has extensive experience supervising installation, testing, and commissioning of control systems for gas turbines and other power plant equipment.