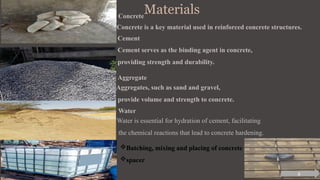

This report details the internship experience of Abel Sisay at Birhan Tobiyaw Building Contractor, focusing on building construction projects. It covers the hosting company's background, internship responsibilities, and benefits gained, including skill development and increased knowledge in construction practices. The document concludes with recommendations for both the company and the university to enhance future internship experiences.