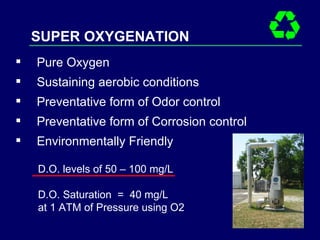

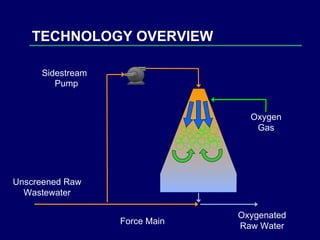

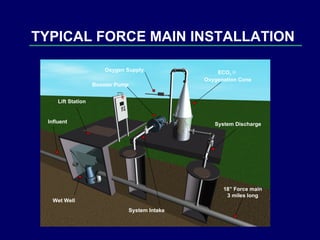

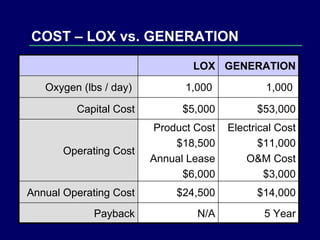

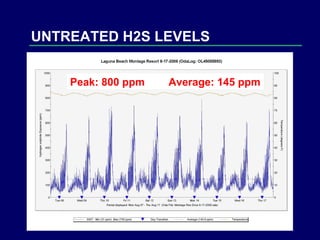

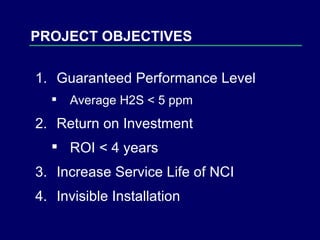

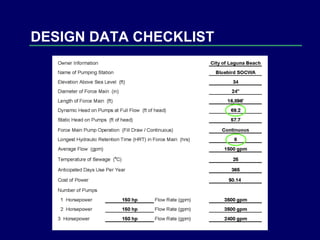

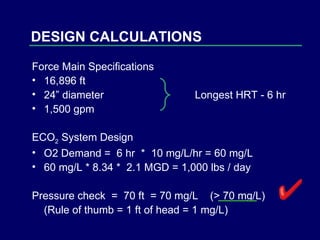

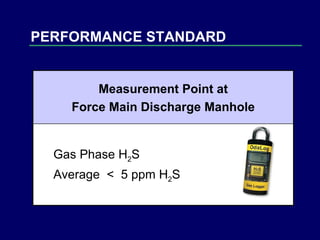

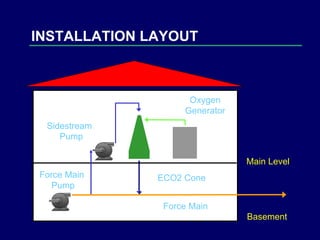

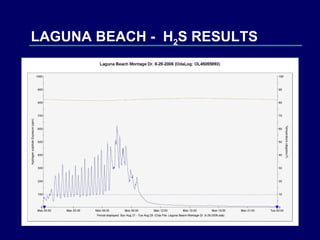

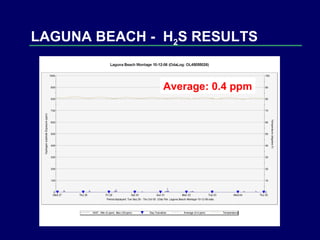

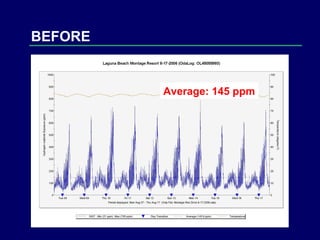

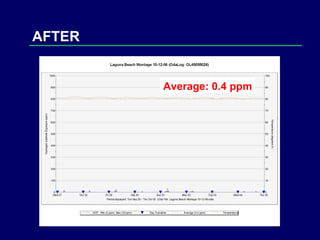

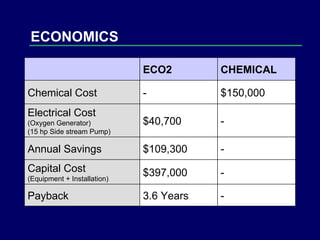

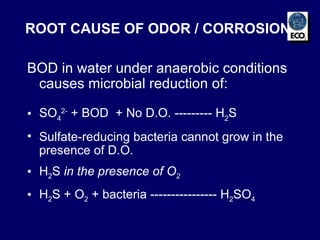

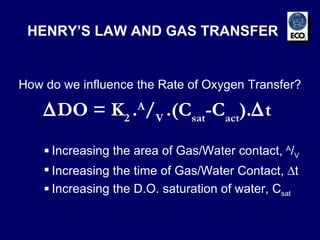

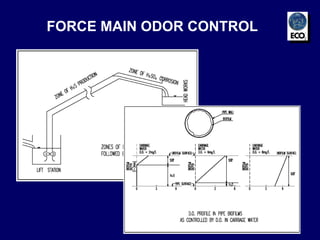

This document discusses odor control in wastewater force mains through superoxygenation. It describes two approaches to odor control - using chemicals or scrubbers to treat odors after formation, or preventing odor formation through superoxygenation. The document then provides details on a specific force main odor control project in Laguna Beach, CA where superoxygenation was used, reducing hydrogen sulfide levels from an average of 145 ppm to under 0.4 ppm.