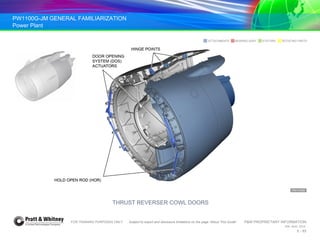

The document provides an overview of the PW1100G-JM turbofan engine power plant. It describes the key components and systems that make up the nacelle, including the inlet cowl, fan cowl, thrust reverser cowl doors, engine mounting system, and engine drain system. It also lists specifications for the engine and aircraft it powers.