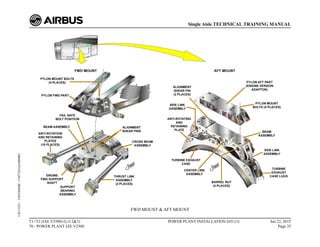

This document provides an overview of the power plant system components for the IAE V2500 engine installed on Airbus Single Aisle aircraft. It describes the location of key engine components including the FADEC, starting system, fuel system, air system, oil system, and thrust reverser system. The FADEC and alternator are located on the engine core and gearbox. The starting components are on the right side of the engine core. Fuel system parts are mostly on the left side of the engine and gearbox. Air system bleed valves are on both sides of the engine core. Oil system components are situated on the gearbox. The thrust reverser hydraulic components are located in the pylon and above the engine.