The document provides details about a manually and power operated reaper machine. It discusses the working and construction of the machine. The key points are:

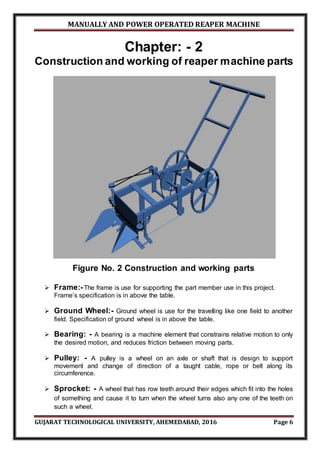

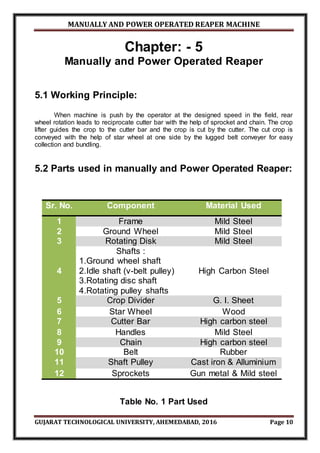

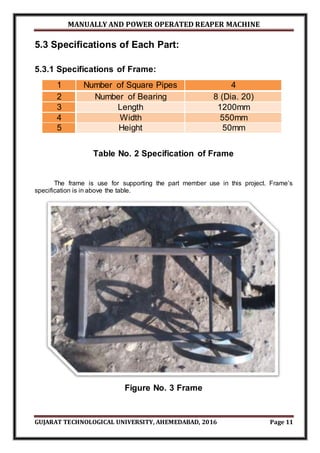

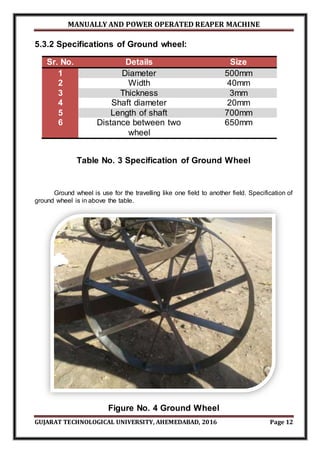

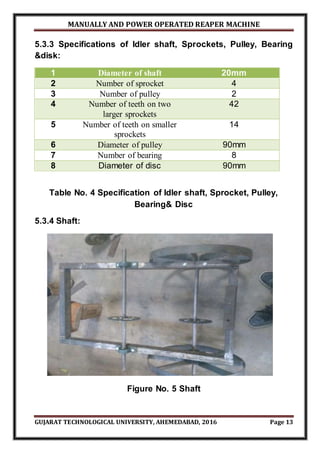

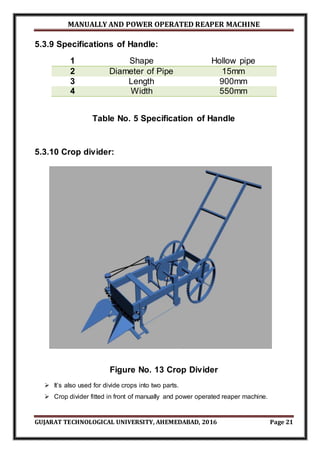

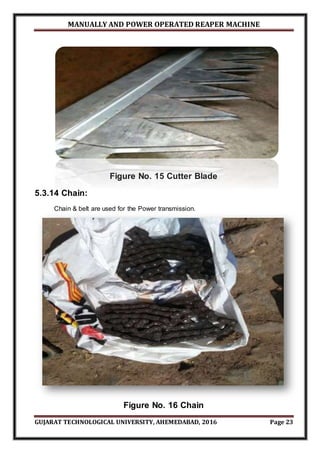

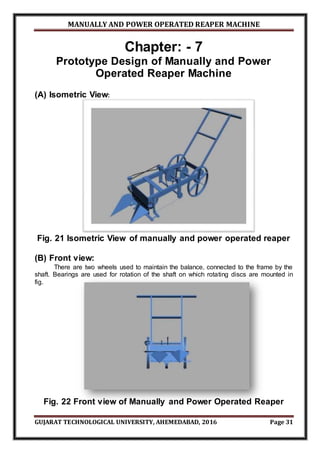

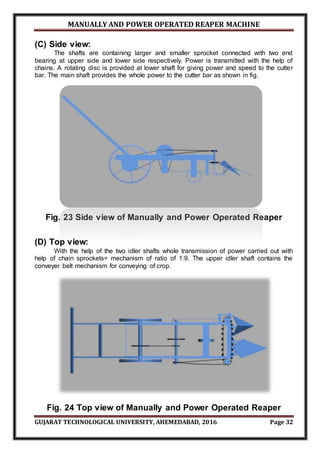

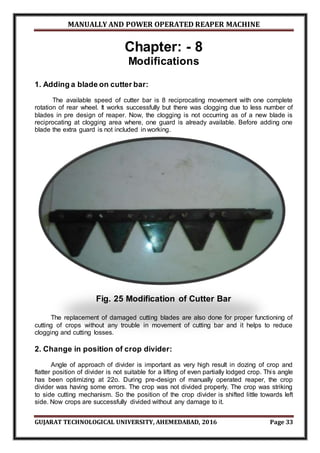

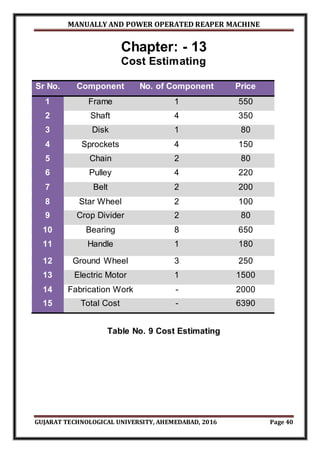

1. The machine consists of a frame, ground wheels, bearings, pulleys, sprockets, belts, chains, and a cutter bar to cut crops.

2. It can be operated manually or with a power source. The power source turns the rear wheels which uses sprockets and chains to power the cutter bar.

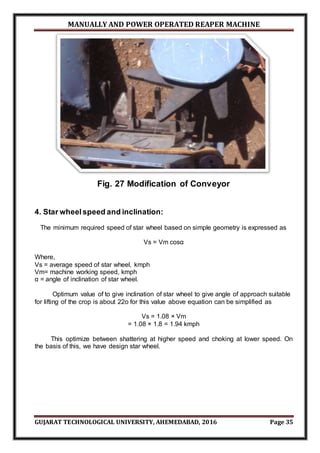

3. The cut crops are conveyed to the side by a star wheel and lugged belt conveyor for easy collection and bundling.

4. The document discusses the target market for small rice farmers and provides