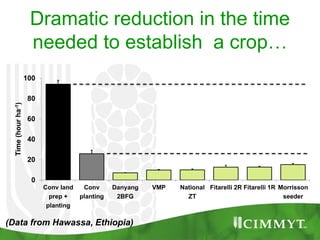

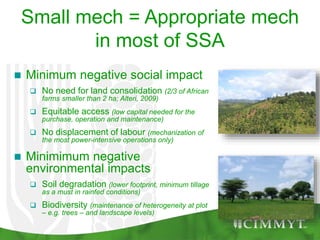

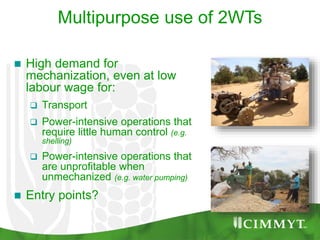

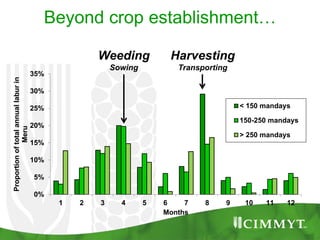

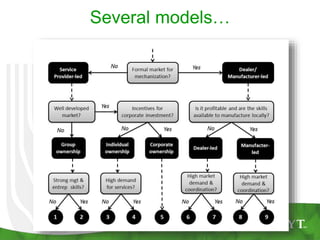

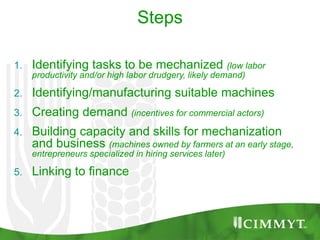

The document discusses the opportunities for mechanization in conservation agriculture (CA) systems in sub-Saharan Africa, highlighting challenges such as labor shortages and declining use of draught animals. It emphasizes small mechanization as an appropriate solution, minimizing social and environmental impacts while improving productivity. The document outlines various models for commercializing small mechanization, suggesting strategies to build demand and link financing to the mechanization process.