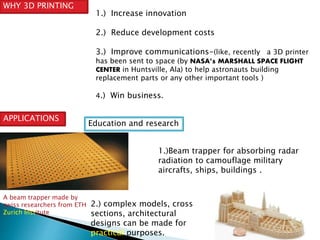

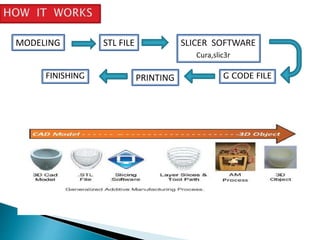

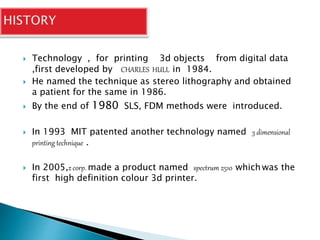

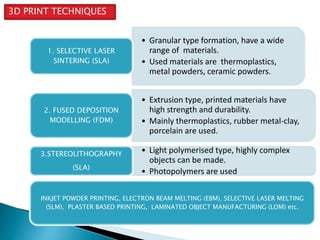

3D printing refers to methods of printing 3D objects through additive processes that lay down successive layers of material with the help of a computer. Objects of almost any shape can be printed using technologies like stereolithography, fused deposition modeling, and selective laser sintering. 3D printing offers benefits like increased innovation, reduced development costs, improved communication, and new business opportunities across industries like education, medicine, automotive, and more.

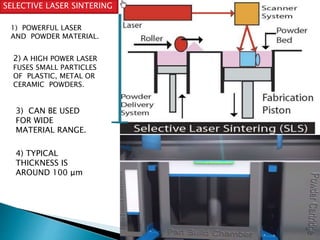

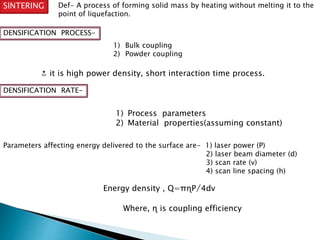

![1.) Sintering temperature, T(s)= T(0) +1/C [ πɳ/4ρ (P/hvw) - ΔH ]

it is a empirical relation.

where, w is layer density , C is specific heat, T(s) is sintering temp ,

T(0) is initial temp, ρ is density and ΔH is latent heat.

2.) The rate of change in void fraction of powder bed is ,

d€/dt = -k€, €(i) ≤ € ≤ €(s)

where k is sintering rate and € is void fraction.

3.) empirically , k ⋉ P/wh

4.) Full densification can not be obtained](https://image.slidesharecdn.com/3dprinting-141019081925-conversion-gate01/85/3d-printing-science-8-320.jpg)