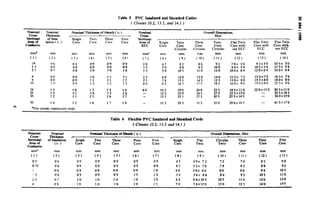

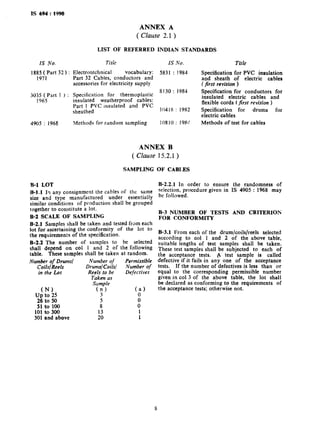

This document is the Indian Standard specification for PVC insulated cables with copper or aluminum conductors for voltages up to 1100V. It outlines the scope, references other relevant standards, defines key terms, and specifies requirements and tests for various cable types and components including conductor, insulation, sheath, construction and testing. The document aims to align standards with international practices while taking into account experience since previous revisions. It provides details on material and performance requirements for fixed wiring, flexible cables and cords to ensure safe and reliable operation.