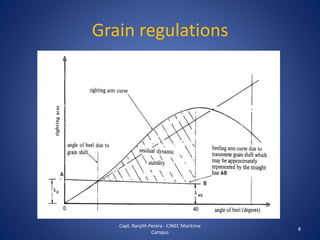

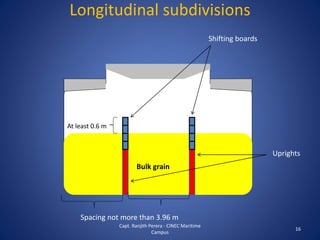

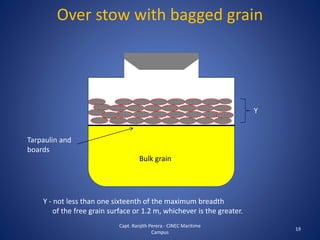

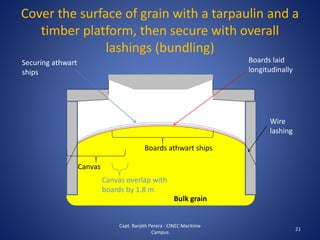

This document discusses regulations and procedures for safely carrying grain cargo. It covers types of grain, dangers of grain shifting, requirements of the International Code for the Safe Carriage of Grain, documents required for loading, and methods for securing grain in fully and partially filled compartments including longitudinal subdivisions, overstowing with bags, and covering surfaces with tarps and securing with lashings or wire mesh.