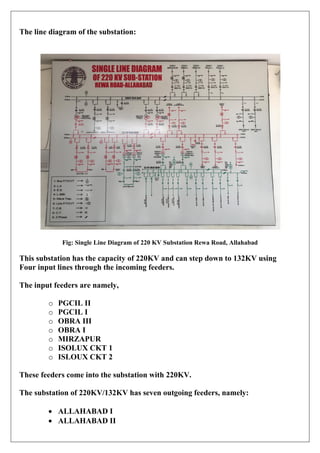

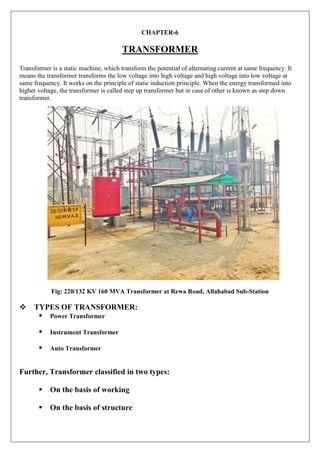

This document is an industrial training report submitted by Swapnil Kumar Gupta for their Bachelor of Technology degree in Electrical Engineering. The report provides an overview of Swapnil's 2-week industrial training at the 220kV substation in Rewa Road, Allahabad, which is operated by Uttar Pradesh Power Transmission Corporation Limited. The report includes details about the equipment and processes at the substation, as well as declarations, acknowledgements, and chapters covering topics like the selection of substation sites, common equipment used in 220kV substations, and descriptions of the transformer and other components.