2-2 Municipal Solid Waste GenerationGeneration and Managem.docx

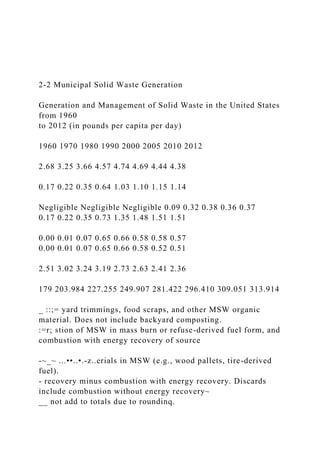

- 1. 2-2 Municipal Solid Waste Generation Generation and Management of Solid Waste in the United States from 1960 to 2012 (in pounds per capita per day) 1960 1970 1980 1990 2000 2005 2010 2012 2.68 3.25 3.66 4.57 4.74 4.69 4.44 4.38 0.17 0.22 0.35 0.64 1.03 1.10 1.15 1.14 Negligible Negligible Negligible 0.09 0.32 0.38 0.36 0.37 0.17 0.22 0.35 0.73 1.35 1.48 1.51 1.51 0.00 0.01 0.07 0.65 0.66 0.58 0.58 0.57 0.00 0.01 0.07 0.65 0.66 0.58 0.52 0.51 2.51 3.02 3.24 3.19 2.73 2.63 2.41 2.36 179 203.984 227.255 249.907 281.422 296.410 309.051 313.914 _ ::;= yard trimmings, food scraps, and other MSW organic material. Does not include backyard composting. :=r; stion of MSW in mass burn or refuse-derived fuel form, and combustion with energy recovery of source -~_~ ...••..•.-z..erials in MSW (e.g., wood pallets, tire-derived fuel). - recovery minus combustion with energy recovery. Discards include combustion without energy recovery~ __ not add to totals due to roundinq.

- 2. MSW Generation, kg/per capita, Kaunas, LT,2010 ~------------------~--------------~--- --- ~~-----------1r-:-------------; • Hazardous • Wood • Terrapaks Other inorganic • Yard waste • Glass • Other organic • Food waste • Other metals • Ferrous metals • Plastics Paper and cardboard ::xample for seasonal changes in household waste composition. Source: [32] III WI ,. I ctln om n ' ant 9 'f W dy bicm I~ s. In addition, in diff " II ~O%.47 discussed here make II (anaerobic digestion < II I ere the specific organi I" sd or isolated, and the pr«

- 3. ::omposting and anaerohl -sed of only one chemi , .e processes are numerou as one would describe 'Iii ANAEROBIC ons (absence of free oxygen] ::::H 4 ), carbon dioxide (CO) (NHJ, and a few others. T, ~l prompted wastewater trC,l1 waste solids and capture Ihl inery in the treatment plant ewater treatment plant is nllt J the potential for producin .erit. on dioxide can be calculaiul II) 2 + dNH3 II If' (11 chemical compositioi f I III I II~ urln the anaerobic n ral formula for glucose is C6H,206; hence by the equation v , a = 6, b = 12, c = 6, and d = O. II ° (24 - 12 - 12)H ° (24 + 12 - 12)CH (24 - 12 + 12)CO

- 4. h " 6+ 4 2 ~ 8 4+ 8 2 ,,""'12°6 ~ 3CH4 + 3C02 j(' that the equation balances. The molecular weights are 180 ~ (1 ) + 3(44); hence 1 kg of glucose produces 0.73 kg of CO2 and () I kg of CH4• Recalling that 1 gram molecular weight of a gas at , I indard temperature and pressure occupies 22.4 liters, the pro- dll cion of CO2 and CH4 from 1 kg of glucose is 746 liters each of III hane and carbon dioxide. 1111(' rtunately, the chemical composition of MSW is difficult, if not impos- ", (I d t rrnine, although some attempts have been made to do so. The best 11111 IIIW tion is that the organic fraction of refuse can be described by the "t/1 II rmula C99H1490S9N. With this formula, the previous equation esti- II Ih. L the production of methane from a landfill is 257 liters of methane , I II I ra m of wet refuse (total, organic plus inorganic, assuming wet refuse is , I, I I gradable organic). In using this equation, note that the only carbon I 1,111 I rticipate in the production of gas is from decomposable materials, It I () d waste and paper. Other organics, most importantly plastics, do not 111" • to produce gas.

- 5. II,' two ways of generating methane are to capture the gases produced in 11111 r to digest organics in an anaerobic digester using tanks similar to those I 11 W stewater treatment plants or another structure, such as a horizontal orI" linder. Methane generation both in anaerobic digesters and in landfills II I II. d in this section, although a more complete presentation of landfill gas ,,111I1 in is found in Chapter 8. Much of the following anaerobic decomposition 111 liPI lies to both processes, however. Anaerobic Decomposition in Mixed Digesters I 'III a ic metabolic pathways for the decomposition or degradation of wastes "lfl(,/e (with oxygen) and anaerobic (in the absence of oxygen). While an aerobic ( 111 ,iii ht be generally represented as 1"11111 organics] + oxygen ~ CO2 + Hp + NO; + SO~2 + other products MEE 5901, Advanced Solid Waste Management Unit V Assignment This assignment will allow you to demonstrate the following objectives: · Assess the fundamental science and engineering principles of solid waste management. · Examine the impact of solid waste on human populations.

- 6. Instructions: Biological treatment of municipal wastes are the primary means for degrading organic matter and for stabilizing the contents of the landfill. Both aerobic and anaerobic processes are functioning in landfills and compost piles. The majority of regulations are set up to protect these biological populations from being killed off or limited in their ability to complete the degradation cycle. The methane by-product can be used as an energy source to help reduce operating costs and to limit the release of a very strong greenhouse gas into the environment. This assignment will allow you to further explore these concepts. Answer the questions directly on this document. When you are finished, select “Save As,” and save the document using this format: Student ID_Unit# (ex. 1234567_UnitI). Upload this document to BlackBoard as a .doc, docx, or .rtf file. The specified word count is given for each question. At a minimum, you must use your textbook as a resource for these questions. Other sources may be used as needed. All material from outside sources (including your textbook) must be cited and referenced in APA format. Please include a reference list after each question. 1) Navigate to the CSU Online Library and review some articles on landfills and on compost piles. This assignment is not about summarizing these operations but about analyzing and comparing the differences between these two fundamental principles of solid waste management. Describe when and why each of these fundamentals is appropriate for use to manage municipal solid waste. Include in your discussion details about the differences of microbial mechanisms, the end products of degradation, and of factors that help and harm the performance of these operations. How effective is each one? (Your total response for all parts of this question should be at least 500 words.)

- 7. 2) A community of 62,000 does not have a municipal recyclinge program, and they it sends all of their its refuse to the municipal landfill. Will the landfill generate enough natural gas to meet the needs of the city if the municipality needs to annually generate 10 million cubic meters of natural gas (methane) and the city collects all of the methane that is generated? How will this affect the population of the city? Explain your answer. (Your total response for all parts of this question should be at least 300 words.) MEE 5901, Advanced Solid Waste Management 1 Course Learning Outcomes for Unit V Upon completion of this unit, students should be able to: 1. Assess the fundamental science and engineering principles of solid waste management. 7. Examine the impact of solid waste on human populations. Reading Assignment Chapter 6: Biological Processes

- 8. Unit Lesson The two key biological operations that are used in the treatment of municipal solid waste are composting and landfilling. Composting is an aerobic process. This is why compost piles need to be periodically turned to allow oxygen to diffuse into the microbes in the compost pile. Compost piles are ideal for treating highly organic wastes that include food wastes, garden wastes, yard and park wastes, and dewatered sludges from municipal wastewater treatment plants. The biggest advantage of compost piles is their ability to stabilize wastes, which results in the volume reduction of waste materials. Depending on the rate that organic materials are applied to the compost pile and on the health of the microbial population in the pile, periodic additions of new waste can be made to the pile. Treating readily biodegradable organic wastes in compost piles results in carbon dioxide being emitted. Besides reducing waste volumes, compost piles are capable of destroying pathogens that are contained in the waste. Stabilized waste that is free of metals and hazardous wastes can be packaged and sold as a fertilizer. Municipalities that use compost as a revenue source must control the chemical content of the waste going into the pile and perform toxicity and metal testing on the stabilized contents to confirm the safety of the product. In the case where stabilized compost piles are not to be placed into commerce, the compost can be used as a soil additive to agricultural lands (which also requires testing to confirm the absence of toxic compounds and metals) and as a soil fill to reclaimed land. The microbial population of municipal landfills operates by a

- 9. different biological mechanism. Landfills operate by means of anaerobic processes that treat and stabilize waste refuse. Anaerobic degradation processes function in the absence of oxygen. This category of microbial treatment is associated with the production of methane that can be captured, compressed, and used as a fuel source to support combustion processes capable of producing energy and electricity. The methane generated by landfills can have an adverse impact on atmospheric conditions. Methane is 25 times more powerful than carbon dioxide when their global warming impact is considered (United States Environmental Protection Agency, n.d.). This is one of the reasons that methane is collected for energy conversion. Even landfills that have a well designed methane gas collection system will experience at least a 10% leakage rate to the atmosphere. In Europe, mechanical-biological treatment of municipal solid waste is becoming popular. Mechanical treatment utilizes separation processes like shredding and crushing operations to prepare the waste for composting or for landfilling. These combination operations break down the refuse into particle fractions. With a standardized particle size, municipalities in Europe have experienced a 40 to 60% reduction in the amount of waste going to landfills. The European Union (EU) also has experienced that by using separation processes as a pre-treatment, it changes the waste profile and particle size of what goes into landfills. This has resulted in pulling out readily degradable organic content from the landfill that leads to a reduction of the generation of methane by 95%. UNIT V STUDY GUIDE

- 10. Role of Biological Processes in Stabilizing Municipal Solid Waste MEE 5901, Advanced Solid Waste Management 2 UNIT x STUDY GUIDE Title Europe is also developing advanced technologies for treating municipal solid waste. These include in-vessel treatment processes that can be located inside a building structure. These include tunnels, vertical towers or silos, rotating drums, and housed bays with forced mechanical aeration and agitation. Tunnel composting utilizes rectangular vessels that use push walls for moving the refuse through the system. Tunnels operate in a batch mode, but new continuous flow systems are starting to be piloted. These units are loaded from the top and aeration is through pipes and slats in the floor. Cool air is used both as an oxygen source and for keeping the temperature in the correct range. Moisture is added to the compost by an overhead spray system. Vertical compositing operates as a plug flow reactor that continuously moves the refuse through the system. Waste enters the top of the tower and is removed from the bottom. These tower systems mostly utilize a

- 11. passive aeration system, but where there are multiple chambers that may be utilized, forced aeration systems become necessary. Rotating drums also operate in a continuous flow through system. The refuse is mixed by the baffles during the rotation of the drum. Aeration can be either passive or forced depending on the amount of refuse being treated. The drum is unique in that it can break open plastic bags and release the contents. The energy of rotation breaks the size of the larger materials, and, with a long enough retention time, the unit can eliminate the need for a shredding operation. Long bays inside of buildings store waste in piles. Augers are primarily used to turn over the waste piles to allow oxygen to penetrate to the microbial populations. During the turning process, the refuse is moved towards the end of the pile. The floor is often fitted with a forced air system to keep the piles aerobic and to keep a high rate of refuse stabilization. Odors are captured and prevented from escaping to the inside of the building and to the outside by a negative pressure system and high room air exchange rate. The air containing the odor is scrubbed in a chemical bath that destroys the odors. Another interesting technology is to dry the refuse as a pretreatment step referred to as bio-drying. The waste is heated, and air is passed through the heated refuse, which dries the waste and lowers the water content of the mixture. The efficiencies of mechanical and separation technologies are greatly improved when the waste enters these unit operations in a dry condition. Advanced treatment processes produce a superior compost

- 12. product for sale in commerce. The EU is adopting manufacturing technologies and principles to treat municipal solid wastes. The revenue that is generated from the recycled materials pulled out of the waste helps to offset the high capital and operational costs of the equipment and staff needed to operate and maintain these systems. Keeping readily degradable organics out of the landfill greatly reduces the amount of methane that is generated and that needs to be captured and managed. The use of compost piles also treats refuse that could go into the landfill, which reduces the operating life of the facility for the community. By keeping organics out of the landfill, obnoxious odors are not generated and emitted into the atmosphere and downwind communities. In Europe, land is at a premium, and wastes are generally handled on a regional basis rather than by each individual community. The EU driver is a lack of available space while the driver for municipalities in the U.S. will be economics. For now, due to the high costs of using advanced treatment technologies, technology adoption in the U.S. will be low and limited to regions with a high density population. However, this may change as landfills built in the 1980s begin to fill up and new facilities become very costly to design, build, and permit. Municipalities will begin to look to privatize these services, and it will be these service providers who will begin to implement many of these technologies as they look to regionalize solid waste treatment for the communities in which they operate. Reference

- 13. United States Environmental Protection Agency. (n.d.). Overview of greenhouse gases. Retrieved from https://www3.epa.gov/climatechange/ghgemissions/gases.html MEE 5901, Advanced Solid Waste Management 3 UNIT x STUDY GUIDE Title Suggested Reading The topic of treatment of organic wastes, which is covered in this unit, is explored more in the article below. Take a few minutes to read this article to gain a deeper understanding of this topic. Zupancic, G. D., & Grilc, V. (2012). Anaerobic treatment and biogas production from organic waste. In S. Kumar (Ed.), Management of organic waste (pp. 3-28). Retrieved from http://www.ewp.rpi.edu/hartford/~ernesto/S2014/SHWPCE/Pape rs/SW- BiochemicalTreat/Zupancic-OrganicWaste-AnaerobicTreat.pdf http://www.ewp.rpi.edu/hartford/~ernesto/S2014/SHWPCE/Pape rs/SW-BiochemicalTreat/Zupancic-OrganicWaste- AnaerobicTreat.pdf

- 14. http://www.ewp.rpi.edu/hartford/~ernesto/S2014/SHWPCE/Pape rs/SW-BiochemicalTreat/Zupancic-OrganicWaste- AnaerobicTreat.pdf I CSU Math Center | 1-800-977-8449 x6538 | [email protected] Math Center Requests: Math Center Request Form Natural Gas Generation at a Landfill LINK: http://columbiasouthern.adobeconnect.com/p8uq6mujllb/ Problem: A community of 50,000 people does not have a municipal recycling program, and it sends all of its refuse to the municipal landfill. Will the landfill generate enough natural gas to meet the needs of the city if the municipality needs to annually generate 15 million cubic meters of natural gas (methane) and the city collects all of the methane that is generated?

- 15. Additional information: * Each resident generates 4.38 lbs. of refuse per day (see p. 43). * Each pound of refuse generates 257 liters of methane (see p. 239). Solution : To calculate the quantity of methane 4.38 �� ������ ∙ ��� × 50,000 ������ × 257 � ���ℎ��� �� �� ������ ×

- 16. 1 �3 1,000 � × 365 ��� 1 ���� = ��, ���, ��� �� Therefore, 20.5 million m3 of natural gas is produced per year. Yes, the landfill will generate enough natural gas to meet the needs of the municipality. mailto:[email protected] https://mycsu.columbiasouthern.edu/student/forms/courses/math -center-request/ http://columbiasouthern.adobeconnect.com/p8uq6mujllb/?OWA SP_CSRFTOKEN=6a590a2ccc5ebcb1e022d036045805ab0797e3

- 17. 59cb0d297096c9f4a96d9b7ee1 Okay, this problem discusses determining if a community of 50,000 people who do not have a municipal recycle program and they send all of their refuse to the municipal landfill. The question is, “Will the landfill generate enough natural gas (methane) to meet the needs of the city if the municipality needs to annually generate 15 million cubic meters of natural gas and the city collects all of the methane that is generated?”. Here’s additional information you need to know. Each resident generates 4.38 pounds of refuse per day, and the information came from page 43. Each pound of refuse generates 257 liters of methane, and that would be on page 239. So we’re literally going to see how much methane can be created with the waste adding 50,000 people. You use literally what you read in here: 4.38 pounds of refuse generated per person, per day times 50,000 people. So we’ve got that number. We’ve taken care of

- 18. this. And now, this is where you kind of have to think about, “what else are we talking about?”. Here’s our additional information. The 257 liters of methane and that’s per pound of refuse—that’s what it says here—per pound. So there’s that. And then, we are going to convert that to cubic meters because here’s what we’re looking for: will there be enough? At least, you’ve got to have at least 15 million at the minimum. So 1,000 liters is equivalent to one cubic meter, and then we have 365 days in one year. So we have pounds, and pounds are gone. And then we have our people, and then our day, and then our liters, and the year is part of this. So we literally take the 4.38 and multiply by 50,000, and multiply by 257, then multiply by 365 equals. Then, divide it by 1,000, and you will get 20,543,295 cubic meters per year. I didn’t write per year here, of methane, which is plenty. So as long as it at least generates 15 million, well it generates 20 million. So the answer is yes, the landfill will generate enough gas to meet the needs of the municipality.

- 19. 11111"11 1 III 'I III HIiIIl'1 ill IIII I /10111 1111' II I ,Ill, I /11' 'I Willi WOldt! h' III(' II flIH' I 1'111 It 01 111111 1111/ uuu ('nil Iw III Iii I I I,O'VtI I -cov 'I Y or 111,11,', ,II , III' , 1'''1('1, will I will I I' tlu 1'"11 0/ 111' , Il'a I with res] I'll tll m.u ','I,tI /? 5-33_ A ordlng I Pig II' - 0, is II I'll 10 1111)1 t Iy s parat one 01 1111 m t rials from th oth 'I' Ihl"" I your answer. 5-34_ Using Figure 5-27, what is IIH' advantage of the susp nett' I I 111 magnet over the other two IYlh" of magnets? /

- 20. . / gical Processes / I 1 r fuse contains ab.o_ut~75%organic material, which can be con- I l us ful energy by combustion, as discussed in the next chapter, or lul products by biological processes, which is the topic of this chapter. I h three components of MSW of greatest interest in the bioconver- II I rocesses are qarbaqe (food waste), paper products, and yard wastes. III J ir age fraction of refuse varies with geographical location and season. I I Illy habits, of course, affect its composition and quantity, as does the I II lnrd of living. Kitchen garbage grinders in more affluent communities

- 21. " II r r much of the putrescible waste from the refuse stream to the sewer- I' y tem, and the reduction of the garbage fraction is a continuing trend I" United States and in many other countries.' rhe garbage fraction also has by far the highest moisture content of IIY nstituent in MSW, but the moisture is rapidly transferred to absorbent 11,11 ials (such as newspapers) as soon as contact is made. Garbage also , 1 J to be well mixed in MSW, and therefore it is often difficult to find h 11 ifiable bits of garbage in mixed refuse other than the large pieces, such range peels or apple cores. Garbage is even better distributed in MSW

- 22. 11111 waste is shredded. The fraction of paper in MSW tends to remain fairly stable throughout IIII year. However, the total amount of paper discarded has been decreasing. Yard waste generation is seasonal." For example, in some climate I 11 s there is essentially no yard waste generated during the winter months. 237 In 1'1 11, IiI m unt ci y. r I w, I reflecting th w th ,An 1m I • yard waste is the amount of lignin HI decompose in biological processes, A th nt g increases in yard waste, the lignin cont nt in r 5 5, In ad

- 23. tree species the lignin content varies from 15 to 40%,47 The two methods of biological conversion discussed h I C of the organic fraction of refuse, The methods (anaerobic dl composting) are broad-spectrum processes, where the spe in I II I " responsible for the bioconversion are not identified or isolated, dill III, cesses are described by empirical data, Because composting n ~ .III I , digestion do not begin with raw material composed of only 01 I" ,,,I the specific biochemical reactions involved in these processes ar 1111111, and therefore it is not possible to approach them as one would d ',I II11 hydrolysis of cellulose, ()( Iy I t i i 11, II lill

- 24. 6-1 METHANE GENERATION BY ANAEROBIC DIGESTION When organic matter decays under anaerobic conditions (absence of free II I' I the end products include gases such as methane (CH4), carbon dioxide (I II small ~~ounts of hydrogen sulfide (H2S), ammonia (NH3), and a few 01""1 I recognmon long ago that methane is an excellent fuel prompted wastew.uei II ment plant design engineers to digest (decompose) waste solids and captuu II gas for use in heating buildings and running machinery in the treatment 1'1 I While the quantity of methane generated in a wastewater treatment plant I II sufficient to consider its conversion to pipeline gas, the potential for PI()dlllll pipeline gas from decomposing refuse has a lot of merit. Ideally, the production of methane and carbon dioxide can be c.lI"tlIH using the following equation:

- 25. C H ON + (4a - b - 2c + 3d) a bed 4 H20 ~ ( 4a + b - 2c + 3d) (4a - b + 2c + 3d) 8 CH4 + 8 CO2 + dNH3 Example 6-1 illustrates how this equation can be used ifthe chemical compos 11111 of a material is known. f C 1"111 (II, 111111111111 n ral formula for glucos i C611'2 6; h nc by the equation = 6, b = 12, c = 6, and d 0, H 0 (24-12-12)HO (24+12-12) (24-12+12) ~ '7 6 + 4 2 ~ 8 CH4 + 8 C IIH,P6 -- 3CH4 + 3C02 N that the equation balances. The molecular weights are 180 ~ 1(16) -I- 3(44); hence 1 kg of glucose produces 0.73 kg of CO2 and

- 26. () 27 kg of CH4. Recalling that 1 gram molecular weight of a gas at I ndard temperature and pressure occupies 22.4 liters, the pro- luction of CO2 and CH4 from 1 kg of glucose is 746 liters each of III thane and carbon dioxide. III) ~ rtunately, the chemical composition of MSW is difficult, if not im pos I hi 10 leterrnine, although some attempts have been made to do so. Th best 1"11 Irna tion is that the organic fraction of refuse can be described by th l' III L I formula C99HJ490S9N. With this formula, the previous equation 'sli lit that the production of methane from a landfill is 257 liters of methane I I I) ram of wet refuse (total, organic plus inorganic, assuming wet refus is , I bl degradable organic). In using this equation, note that the only carb n II 1,111 participate in the production of gas is from

- 27. decomposable materials, II II ,IS food waste and paper. Other organics, most importantly plastics, do riot 1111111 ose to produce gas. 'I'h two ways of generating methane are to capture the gases produced in 110111 or to digest organics in an anaerobic digester using tanks similar to rhos I" 11wastewater treatment plants or another structure, such as a horizontal or 1I11.tIcylinder. Methane generation both in anaerobic digesters and in landfills "I u sed in this section, although a more complete presentation of landfill gas 1,"111lion is found in Chapter 8. Much of the following anaerobic decomposi tion 1111 applies to both processes, however. 1 Anaerobic Decomposition in Mixed Digesters I IWO basic metabolic pathways for the decomposition or degradation of wastes

- 28. aorobio (with oxygen) and anaerobic (in the absence of oxygen). While an aerobic 111 n might be generally represented as II implex organics] + oxygen ~ CO2 + H20 + NO; + SO~2 + other products the ana .rohk d '( OlliIH), rlun of' ()1l,1I III It' Ii ' II Iwd ,I [cornpl x or), IIi 81 I water :OJ I :11.1I 11/ I Nil.: The end products in aerobi d omp sil iOIl II '.111 Iill k, I (}ss('ssilllJ,1I1l.ld.11I energy to be used by decomposing org, ni!ltnll (tlwy :II" ,I th - ir 1111,111'11I' hi state). The products of anaerobic decorn] sition, on rh th r hand, .1 III' I energy. Ammonia and hydrogen sulfide could be slill furth r oxidlzed, .111111 ane contains considerable energy. The microorganisms responsible for anaerobic decomposition (.111I" III

- 29. into two broad categories: 1. Acid formers that ferment the complex organic compound: III II simple organic forms, such as acetic and propionic a i Is. '1111I II organisms can be either facultative or strict anaerobes. 2. Methane formers that convert the organic acids to methan . TlwsI' 11111111 are strict anaerobes and have very slow growth rates-two ('11.11.111111 that cause considerable problems in anaerobic processes ill W,I II treatment and will similarly plague anaerobic decomposition III I. It Methane formers arc very sensitive to various environmental /.111111 I are strict anaerobes and quite sensitive to temperature changes. '('Wit .nu ent groups of methane formers seem to exist: one group (mesofJlli/, ) , IIIII ing best around 30 to 38°C (85 to lOO°F) and a second group (1/1('1 IlIfI/I/111 operating best around 50 to 5SoC (120 to 135°F). The metharu

- 30. IltllIl also require stable and neutral pH. Sufficient alkalinity (resist.u It. lit' drop) should be present to prevent the pH from falling below (1,/1 111111 methane formers are sensitive to the presence of toxic materia I:,. 'III II heavy metals and pesticides. During the acid-forming stage, the first step in the process involves I II •• lular enzymes produced by acid formers, which break down the large 11111111 organic molecules. For example, the enzymes cellobiase and cellulase bl(',11 till cellulose to glucose, and lipase breaks fat to shorter-chained fatty acids. '1 "' pi cess is energy consuming. Other bacteria then metabolize the glucose and other products into III acids, mostly acetic and propionic acid. These simple organic acids thcn : I I I substrate for methanogens. This methane formation is performed by a nun 1111I

- 31. organisms that have specific substrates and roles in the overall reactio n. '11" 1 reactions CH 3 COOH ~ CH4 + CO2 4CH 3 CH 2 COOH + 2Hp ~ 7CH4 + 5C02 for acetic and propionic acids, respectively, are actually the net results oi " 1111 number of steps. The resulting gas varies in composition but averages ,Iltllll 60% methane with a heating value between 500 and 700 Btu/ft" (47()t) II 6500 kJ/m3) 3 The total amount of gas theoretically available from the anaerobic dil',l'llllt I

- 32. of MSW is considerably more than has been captured to date in pilot plant Lu III ties. Aboul54% of th volatil solids have been found to pass through the dil'.I'~hI and have not been onvcrt d LO 1 and CH4· Total gas 0.3 production (m3/kg volatile 0 2 solids added) . 0.4 __ --6(fC __ --5(fC 4O"C __ -4S'C------//--- ;' ;' /

- 33. I / I 0.1 5 10 15 20 25 Digester detention time (days) - ---------- 6 1 Gas production from anaerobic digestion of MSW. Source: Based on . T d J C L · bman "Energy from Refuse by Bioconverslon FermentatIon an . . Ie / . 1 295Idu~ Disposal Processes/" Resource Recovery and Conservation: . Pinnll ,lOx 111:11('11111, ('1111 lit' d 'II 1111'/111111) ,1111 'I' Ihlt I H', 1011, IIIII! II must be ntrolle II y 1'('111 lYIlIg poll'lIl .11 I I /I I '101'(' 111'

- 34. H'I lO 1111' 1111' II t present in the dig st r th Y must l 'I '1IIOV('d II I I III lI011 01' PI' '( (11111111111 III latter method has b n su ssfully al'l I xl ln old '1'10 !'t'Il)( vc II) 'Ialll wlll: 111111 in wastewater treatment plant .7 MSW digestion might be des rib' I nil I he lc ny or 1" III uon I" VI tI 1111 ( organic) matter as dS -= -K5 dt d where S = concentration of the biodegradable material (measur d (S vO!.11 II suspended solids, or a specific material if the system f, d is controlled), mg/liter at time t Kd = decay constant, days " t = time, days

- 35. This is simply a first-order decay equation, stating that the rate of decay is pll '1"1/ tional to the organics remaining, a reasonable assumption if the process 1';11(' I 11111 time dependent. After integration, S - = e-K,I 50 where 50 is the original organic solids concentration, at the starting time I " given in mg/liter. The materials balance within a completely mixed continuous digester wot III1 1t [rate of input] - [rate of output] + [rate of positive or negative accumulation] = [rate of net ch;lIl1~I'1 If the digester is operating at steady state, the net change is zero, and Q50 Q5----K5=0 V V d

- 36. where Q = flow rate through digester, m3/day V = volume of digester, m" The accumulation term is negative because the organic material is being des: r<IYI'I 1 The hydraulic residence time is t = Q/ V or _ So - 5 t=--- Kd5 Hence, if Ka is known, the required residence time for any reduction in solids 1.111 be calculated. Batch laboratory experiments can be used to obtain values of I,,, 1'1 plotting the values of log 5/50 versus time and measuring the slope as (Ki2.:() ') Values of Kd for refuse slurries have not been reported. The process kinetics also may be described in terms of the gas produ. 1'./ instead of the volatile matter destroyed. Using a similar mass balance, Pfelll'l found that it was possible to describe the reactor performance

- 37. by the model Co - C _ --"--- = K tC g , 11Itl>(IlHIIll , Il'Odu( ti011 ,111.1Ihd"", , III UI II II 0,1,11'/111'1' 101,11'II ""UI P 'I' W"'111 volatllc : 1111 1111111 I .111111 d: Ily gas I 1'0 III Ii 11, lill'l'lI/I volll! II' III I I Y 11'<uli I' sid n [im', (ill,I'~ rat nsta nt. days 1 "III I) hav two di tinct valu s. 'l'h' Il1lll.lIl'ill' Is rapl I and lasts b tw ·n 5 d III 1,'Ys f Ilow d by a significantly I 1W 'I' 1', I '. '1', bl -1 is a listing of the illl' , AI 4~o there is a substantial dl' pin 1(8 from 40°C, indicating again th . I I' II (' of In sophilic and thermopbilic regimes in anaerobic digestion. 1'/1' [uantiry of gas generated can be estimated by entering a plot (su h (IS 111111 (1 I) at th calculated t (hydraulic residence time) and reading off th g, I'

- 38. I'"" 11 () n. 13 ca use of the heterogeneous nature of the waste and the fact tha t no I 111111' )1' ni s decompose, any theoretical calculations probably would be fruit- I III I' ~ I' , laboratory studies to determine kinetic constants for a particular II' 'n essary. Potential for the Application naerobic Digesters II" Ih 1973 and 1979 worldwide oil crises, when many communities were III d ring waste-to-energy plants, anaerobic digestion was viewed as a lower- I I III I' environmentally friendly alternative method of generating energy. AL 1I1I I III , much of the research was focused on mixed waste low-solids anaerobi III I ('S. However, for a variety of reasons, no large anaerobic digestion plants I" built.

- 39. 'I'h process is plagued by potential problems. There is no way to ensure the lilt ival of toxic materials before the waste goes into the digesters, and "sour" II .! I' (such as those encountered in wastewater treatment plants) are a definite II jUty. Th problem of mixing a paper slurry has continued. Even pilot plant scale 11I1 ng with fairly dilute slurries has been found to be a problem. The desired "I I! ncentration for these digesters is at 10%, which is a highly viscous an I 1,1 6-1 Rate Constants, K for Gas Production in Anaerobic Digesters 9 Rate Constant (day:") , '"f rature, DC Initial Final 35 0.055 0.003

- 40. 40 0.084 0.043 45 0.052 0.007 50 0.117 0.030 55 0.623 0.042 60 0.990 0.040 1111 : [8J thixotroplr lUll ,.111 W,llIll'Wl1! '1'111'111111'111PIIIIII " wll'I' olhl. ('(II' 1'1111I I normally rang fr III :1 10 51},1h,lllixlJ'H 111 IIlwIIY I ('('11 I I rohl 'III. '1'1111'1md have shown that typi al primary lig'MH'1 11'11110 II IV' old 2517h 01 I1III1 ume mixed-the remaining being d 'cd /ojIHI( ',111,'u 11"rot lcms will HIIII'I' III 'I refuse-digestion facilities as well. A I mou tnu on l)Joje tin IIlorid, (0111 1111 break shafts on mixers because of the high fibrQLltl 'Olll nt fth wnlll', Large land areas are required by the digest rs. ( minimum 12 aen's (", hll)

- 41. a 1000 ton/day (900 tonne/day) plant." This an b a problem wh '1'(' 11,1111111 costs prohibit long-range refuse movement and if the treatment fa .ilit 11111 I located on expensive urban land. And finally, the problem of what to d(l 1111II effluent and residue has not been solved. The sludge does seem to Ul'W,111I I ily (as it should) with all the fiber in it, but its ultimate disposal is all ,HltlllllIlI problem in the application of this process. In the last few years there has been more interest in low-solids (I S/l 11'.111III total solids) anaerobic digestion of organic material. Toronto, Canada bill II ,I 1111t plant and is constructing a second plant (Figure 6-2). Sacramento, alif()IIt1,111 has a small facility. These plants are designed to process a source separated 11'1III waste that is suitable for a low-solids facility. For example, food waste is a d."11 IIII feed stock but yard waste is not. To manage all organics, European companies are building h igil

- 42. 1111,1 (greater than 20% total solids) anaerobic digesters. While some plants PJ'()( I' 'I I till source separated organics (such as food waste and green waste), others pll I Figure 6-2 Low-solids anaerobic digester. (Courtesy William A. Worrell) " 6-3 Anaerobic digestion tunnel. (Courtesy William A. Worrell) IIIlUll S that include a significant fraction of nonorganic. A high-solids digestion Ii 111is designed to feed and process "dry" material. Unlike a low-solids system, II I h generates effluent, a high-solids system recycles the effluent to inoculate th ' 11111tin ing feed material. Some designs have no mixing after feeding, and the organ- I III" placed into long, air-tight tunnels (see Figure 6-3). Other designs slowly IIII p rt the material through a vertical or horizontal fermentation drum; this

- 43. I 1I11S in some mixing. Figure 6-4 illustrates the process schematics of three of the 11111'l European manufacturers. Pigure 6-5 shows a Kompogas anaerobic digestion plant near Zurich, , l~ rland, This plant accepts source separated organics, including food waste I 1'111 '0 ) "11 (I 1111l)I II()I 1 Feed Innoculum Loop Digested __ ~ Paste Digested

- 44. Paste Digested Paste . Schematic drawing of various dry-solids anaerobic digesters. Source: AcI,q Ii II avivere, P., L. De Baere, and W. Verstraete, "Types of anaerobic digest I', i." rs, in Biomethanization of the Organic Fraction of Municipal Solid Wast /arez, Editor. 2002, IWA Publishing: Barcelona. pp. 111-140, as used In CUll I III Digestion Technologies Used for Treatment of Municipal Organic Solid WII I ntegrated Waste Management Board, March 2008. © 2008, 2010 by the .11111,,"I vt of Resources Recycling and Recovery (CaIRecycle). All nghts reserved. U'II 1111. ure 6-5 Kompogas anaerobic digestion plant in Switzerland. (Courtesy Willl,1111 Vorrell)

- 45. « I ria 2 Advantages and Disadvantages of Various Anaerobic Digestion Systems Disadvantages llIill I.d I, hlll', 'I'll • W.I, Ii' , .Il!l'dd Ii 11 I II I III I I 1 II h 1I'Iy,OI1l,11 II IIht! Oil h um Ii I' two to 1111'" W('('1 IIII 1111 11111 I" It • "'suIIS in the 1.11111 oj' 111'Illun' for us' • s n 111'1. 'I'll I IIII III Ii 11I111('did( ligestat ,) is I 1I1I11JlOst' I a 'I' bi ally. '1'10' PI'Otil1t I 111'111'111,111' I II 1111I ( d quality I 11111'1 lm 'nt. III 1 I liLi n I dig st rs being 'illll'1' W '101 lli , III 'y nls an be single-stage, hll', I' b l h (a ilities. Single-stage Ii 1 '$( 'I'S are sirn] I l design, build, and I tll' 1111I p rate as a continuous ~ d YSl m. A two-stage digester separates lilt .Ii hydr lysis and acid-producing fermentation from the

- 46. methanogenesis. I I 'ITISare also continuous feed systems. In Europe, most of the systems are I It I.IH' ystems. Finally, there are also batch digesters that are fed initially and II ,Iii IW I to operate. The advantages and disadvantages of the various systems Ii IWI1 n Table 6-2. I. hnical II logical I onomic and I nvironmental Advantages Derived from well-developed wastewater treatment technology Simplified material handling and mixing Dilution of inhibitors with fresh

- 47. water hnical Less expensive material handling equipment llIological conomic and nvironmental Technical Biological Economic and Environmental No moving parts inside reactor Robust (insert material and plastics need not be removed) No short-circuiting Less VS loss in pre-treatment Larger OLR (high biomass)

- 48. Limited dispersion of transient peak concentrations of inhibitors Cheaper pre-treatment and smaller reactors Very small water usage Smaller heat requirement Operational flexibility Higher loading rate Can tolerate fluctuations in loading rate and feed composition Higher throughput, smaller footprint Short-circuiting Sink and float phases Abrasion with sand Complicated pre-treatment Sensitive to shock as inhibitors spr immediately in reactor VS lost with removal of insert fraction In pre-treatment High consumption of water and heat Larger tanks required

- 49. Not appropriate for wet (TS < 5%) waste streams Low dilution of inhibitors with fresh water Less contact between microorganisms and substrate (without inoculation loop) Robust and expensive waste handling equipment required Complex design and material handling Can be difficult to achieve true separation of hydrolysis from methanogenesis Larger capital investment I I Dranco

- 50. Biogas I 0111101-1 I ni()gil, Feed Innoculum Loop Digested Paste Digest d ~ Paste Digested Paste Figure 6-4 Schematic drawing of various dry-solids anaerobic digesters. Sourc-: 1( 1111,j from Vandevivere, P., L. De Baere, and W. Verstraete, "Types of anaerobic digest I', I, ,I solid wastes, in Biomethanization of the Organic Fraction of Municipal Solid Wast "/

- 51. J. Mata-Alvarez, Editor. 2002, IWA Publishing: Barcelona. pp. 111-140, as used in 11111111 Anaerobic Digestion Technologies Used for Treatment of Municipal Organic Solid W,I I California Integrated Waste Management Board, March 2008. © 2008, 2010 by th (11111, ," Department of Resources Recycling and Recovery (CaIRecycle). All rights reserv d. lJ'" I permission. Fiquro 6 5 K mp d Il,) r ic dlllP 111111111 1111111 w II dill l, ( 11I1 'yW11I11I1I 11 W"", "' 6 Advantages and Disadvantages of Varlou III rl , I" Ie I III n mle and Illvlr nmental

- 52. hnlc I II n mle nd l/lvlr nm nt I It Ilnle I Advantages Derived from well-develop d wastewater treatment technol y Simplified material handling n mixing Dilution of inhibitors with fre h water Less expensive material handlh equipment No moving parts inside r act r Robust (insert material and plastics need not be remov d) No short-circuiting Less VS loss in pre-treatm nt Larger OLR (high biomass)

- 53. Limited dispersion of tran i I1t peak concentrations of inhibit I' Cheap r pre-treatm nt nd sm II r r actors V ry sm "W t r us Sm " r h t r qulr m I1t III 11 ·dvantag of V rlou Annol',ohlll In f m .al Advantages Simplified material handling Reduced pre-sorting and treatment Separation of hydrolysis and methanogenesis Higher rate and extent of digestion than landfill bioreactors Low cost Appropriate for landfills

- 54. lie and Tlental 111111111 I I within 15-20 min t 60" °C and within 15-20 mln Less complete degradation I III ,11I1 (leach bed systems) 6-1-3 Methane Extraction from Landfills Landfills are very large anaerobic digesters. However, unlike the pn-vluu I, cussed facilities, landfills are not optimized for gas production. SOI11('«uunm ties have tried to create a bioreactor landfill to increase the rate of stabi I i:tull 1111 I gas production. A bioreactor landfill is operated to rapidly transform a II( I I II III ' organic waste. The increase in waste degradation and stabilization is it colliI'll I through the addition of liquid to enhance microbial processes, Liquid IIIIi

- 55. added to almost the field capacity of the landfilL Field capacity of the 1.111111111 the point at which the landfill is saturated with water prior to any per 01.11"III I can range from 35 to 60% moisture. To achieve field capacity in wast . SI.11I Itl 10 to 20% moisture requires between 40 and 80 gallons per cubic yard of WII 4 The extraction and use of gas from landfills is discussed in detail in 1I,IPII" I Composting differs from the previously discussed anaerobic process in 111.11 II I aerobic process, and the end product is the partially decomposed organic 11.11 II! Composting is often promoted as a "natural" process of solid waste treauurut I reason for this reputation is that compost piles can be readily constru It'd II II backyard, and the product is a useful soil conditioner. It is little wonder, Ihi'll hi that municipal engineers and city councils are besieged by citizens grOllpN11111 that composting be initiated in their community in place of alternative solu I I

- 56. disposal schemes such as landfilling and combustion, which many people v a waste of money and natural resources. 6-2-1 Fundamentals of Composting Aerobic microorganisms extract energy from the organic matter through a St'll exothermic reactions that break down the material to simpler materials. '1'111' " I aerobic decay equation holds: [complex organics) + oxygen ~ CO2 + Hp + NO~ + SO~- + [other less complex organics] + [heat) 6-2 COMPOSTING Ihls decomposition, the temperature increases to.about 70°C (160°F) ~n ,11. perated composting operations. As the reaction develops, the ea.,~Y III III H rs are mesophilic bacteria followed after about a week by rhermophili II I ,, In rinomycetes. and thermophilic fungi." Above 70°C,

- 57. spore-fon~lI1g . d . t As the decomposition slows, the temperature drops. 1111, I! ormna e. d illi d I 1111 ophilic bacteria and fungi reappear. Protozoa, nemato. es. mi ipe es. t 1111118 are also present during the later stages. The concentratIOn of dead and III I II nnisms in compost can be as high as 25%Y . . I II' levated temperatures destroy most of the path?gemc. bactena, eggs; t f the more common pathogens and then survival at ele:ate~I I, . orne 0 hili t g IS h in Table 6-3 The product of thermop 1 lC compos in11" IIIIIIr S are s own 1 . .... III .illy free of pathogens. All potential pathogens, including resistant parasrtes .1 As aris eggs and cysts of Entamoeba hi5toly~ica, are destroyed." . . ritical variable in composting is the moisture co.ntent. If the mlXt~lre IS

- 58. .1 ,Ih microorganisms cannot survive, and compostmg stops. If there. IS to~ 1 II w.u r, the oxygen from the air is not able to pe~etrate to where the microor- , I 1 are. and the mixture becomes anaerobic. TyplCally compos~ should have a. t fb tween 400/0 to 60% The right amount of moi sture. whetherI 1111" onten 0 e ,I . I'd I W t r sludge or other sources of water, that needs to be added to the so 1 S IIII v just the right moisture content can be calculated from a simple mass 111111 : M = moisture in the mixed pile ready to begin compo sting, as percent p . moisture M. = moisture in the solids, such as the shredded and screened refuse, as percent moisture

- 59. In' and 01 dv nt Criteria Advantages Simplified material handling Reduced pre-sorting and treatment Separation of hydrolysis and methanogenesis Higher rate and extent of digestion than landfill bioreactors Low cost Appropriate for landfills Less complete degradation rOil/ ull (leach bed systems) Technical Comp ctlon prevents p r leachate recycling Variable gas production in systems

- 60. ~ Biological ti;:;- u "in ~ Economic and Environmental Source: [44] 6-1-3 Methane Extraction from Landfills Landfills are very large anaerobic digesters. However, unlike the prcviouvlv II cussed facilities, landfills are not optimized for gas production. Som 0 (011111111 ties have tried to create a bioreactorlandfill to increase the rate of stabil iZ.1111I1II gas production. A bioreactor landfill is operated to rapidly transform and dl" I organic waste. The increase in waste degradation and stabilization is accorupll It through the addition of liquid to enhance microbial processes. Liquid 11111I

- 61. added to almost the field capacity of the landfill. Field capacity of th 1.111111II the point at which the landfill is saturated with water prior to any percolnriuu II can range from 35 to 60% moisture. To achieve field capacity in waste SI.III "I 10 to 20% moisture requires between 40 and 80 gallons per cubic yard of W,I I The extraction and use of gas from landfills is discussed in detail in Chapu-t /I 6-2 COMPOSTING . . the temperature in r asl'~ 10 .Ihl I 111 d composltIon, , I I .. d osting operations. As th 1"L°II(11011 I WI'II·op rate comp I .., hilic bacteria followed aft 'I' ;1)OUI ,I 111111,IS are mesop d th hilic fungi.') 11 nv' ,I I . linomycetes, an ermop I, • . As the decomposition slows, IIII' , I ~ I r dommate. p' ,.. b . nd fungi reappear. I' ( :/,0., 11

- 62. 1111 (phlhc actena a '1'1 I nt during the later slag s. W DillIIIIns are a so prese b hi h as 5(!/c1 Il IItrflnisms in compost can e as 19 . "I [1' d atures destroy most f the 1.111 IIII' levate temper ome of the more common pathogens and 111' I I . hown i Table 6-3 The produ ( of IlwlIlIt ur s are sown m· . 11 I. f th ns All potential pathog ns, 11)(111 lit .11 free 0 pa oge . . I '. '. I . d cysts of Entamoeba hlSto .yl IUI, .lIl (I I As ans eggs an . . . I . bl in composting is the moisture ullritica vana e l . isms cannot survive, and ornpos: I I 111 mlCroorgalll, I , th .' ot able to p 'IWII',II,I w.u r, the oxygen from e air IS n ..' . and the mixture becomes anaerobIC: l'ypl all I II are. fb tween 40% to 60%. The right t'lI1HlIlI

- 63. II 111' ontent 0 e h ' I I d ther sources of water, t at n Cl S (11 w,I r s u ge or 0 I" I . th . ht moisture content can be a (1 .1111II v )ust e ng , 1111I : Composting differs from the previously discussed anaerobic process in thai II aerobic process, and the end product is the partially decomposed organic fl.1I lit I Composting is often promoted as a "natural" process of solid waste treatmrui I" reason for this reputation is that compost piles can be readily constructed II II, backyard, and the product is a useful soil conditioner. It is little wonder, 1III'Idill that municipal engineers and city councils are besieged by citizens grou ps 1111I that composting be initiated in their community in place of alternative solid WIII disposal schemes such as landfilling and combustion, which many people vn a waste of money and natural resources.

- 64. 6-2-1 Fundamentals of Composting Aerobic microorganisms extract energy from the organic matter through a ~('I I exothermic reactions that break down the material to simpler materials. The IIi aerobic decay equation holds: [complex organics] + oxygen ---7 CO2 + Hp + NO; + SO~- + [other less complex organics I + [heat] MX + lOaX, Mp = a ~ + X s a . .n the mixed pile ready to bcgi I' I(M = moisture 1 P moisture . in the solids such as the shrcdcl,'M = moisture 1 ' a percent moisture X 111.1, (II oil I , wt'( 1111

- 65. x~= mHSS 01, III Ili' 01 (lIIWI 1)1111' 01 W,II 'I, lOll ('1'111. ,1. 111111' Iii I s lids nt 'nl )1'the , 11Idl' I. Vi'l low, ,I goo I ," II III pi 1111 II a tivat d slu Ig is LIS 'I, will hi, commonly li'ss 111,111 141;1 1;111 sn tons of a mixture of paper and other compostabl I t II iI. III moisture content of 7%. The intent is to make a mixtur r 1I 111111 osting of 50% moisture. How many tons of water or Iu JI 11111 I e added to the solids to achieve this moisture concentr ti II III 1111 ompost pile? M X + 100X (10 X 7) + (100 X X) M = a a s = s = 50 p X+X 10+X s a 5 olving for Xs yields 8.6 tons of water or sludge.

- 66. : the water to be added is expressed in gallons instead of tons, Ilw w,11I1 quation reads MX+0.416W M = a a s p X + 0.00416 W a s Ws = water or sludge to be added in gallons. The other variable ,I :l previously. 11 biochemical conversion processes (such as composting) are i II I ep operations. The first step is the decomposition of complex moll'; lilt materials into simpler entities. If there is no nitrogen available, llil I I lent of the process. If nitrogen is available, however, the second sll'l' I I sis of the breakdown products into new cells. These new microuuuul I Jute to the process, and the system operates in balance.

- 67. -ecause of the high rate of microbial activity, a large supply of nilllllllI ed by the bacteria. If the reaction were slower, the nitrogen could be 1;'1 II ICemany reactions are occurring concurrently, a sufficient nitrogen SIII'III ary. The requirement for nitrogen can be expressed as the CjN ratio, ,~III/I •.CjN of 20: 1 is the ratio at which nitrogen is not limiting the rate ()f dl'llll on. Above a CjN of80:1, thermophilic composting cannot occur, b« ,III~I I ::n severely limits the rate of decomposition. Most systems operate Iwl extremes. Some researchers recommend an optimal CjN ratio of p, I I uio higher than this can increase the time to maturity. Nitrogen can il;'1 III 19 at a Cj N ratio greater than about 40: 115 At higher pH levels, the 1111111 ~lost into the atmosphere as ammonia gas ifthe CjN ratio exceeds I'; I 11'('1'1'',I'. dill 111 1111 1111111"1 I "I 11'0 i1l as the

- 68. merit < rbon concentration in the mixture prior to composting, as percent r total wet mass of mixture rbon concentration in the refuse, as percent of total wet refuse mass rbon concentration in the sludge, as percent of total wet sludge mass l tal mass of sludge, wet tons per day " total mass of refuse, wet tons per day 11I1 p II of the compost pile varies with time, showing an initial drop, then I "I l between 8.0 and 9.0, and finally leveling off between 7.0 and 8.9.16 If , '"IIIIOSL heap becomes anaerobic, however, the pH continues to drop due to , rh III f the anaerobic acid formers. As long as the pile stays aerobic, there is I 111I uffering within the compost to allow the pH to stabilize at an alkaline

- 69. U, I' I Table 6-4 Carbon/Nitrogen Ratios for Various Materials C/N Food waste Raleigh, NC Louisville, KY MSW (including garbage) Berkeley, CA Savannah, GA Johnson City, TN Raleigh, NC Chandler, AZ Sewage sludqe Waste activated Mixed digested

- 71. Source: [15] ( :/1 arbon concentration in the mixture prior to composting, as per nt f total wet mass of mixture ( . arbon concentration in the refuse, as percent of total wet refuse mass 'I ( • arbon concentration in the sludge, as percent oftotal wet sludge " mass " EO total mass of sludge, wet tons per day = total mass of refuse, wet tons per day I III ' I I r of the compost pile varies with time, showing an initial drop, then " I Ill!) l between 8.0 and 9.0, and finally leveling off between

- 72. 7.0 and 8.9.1(, Ir II 1111 )st heap becomes anaerobic, however, the pH continues to drop due ( II I 1m f the anaerobic acid formers. As long as the pile stays aerobic, there is lilt 1'111 buffering within the compost to allow the pH to stabilize at an alkalin X" ())aSH tJl'solllHI W~'1 tun x, = mass of slu lgc or other SOLI I' ~. oi WIIII'I', lOll. ('I'll 11.1ru 1I11H'H 1111 I solids content f th sill lg iH WI low, n goo I nS8UII1III)1III I I activated sludge is used, wh i h is '0 III m Illy I 88 LI a n IIVtI1111111 I Ten tons of a mixture of paper and other compostable m t ri(11111, a moisture content of 7%. The intent is to make a m ixtur -f I (1111' posting of 50% moisture. How many tons of water or slud II111 I be added to the solids to achieve this moisture concentration ill

- 73. IIII compost pile? M = MaX. + 100X, = (lOX 7) + (100 X X) _ p X + X 10 + X-50 s a s Solving for Xs yields 8.6 tons of water or sludge. If the water to be added is expressed in gallons instead of tons, the W.lI,t h ance equation reads MX+0.416W M = a a s p X + 0.00416 W a s where Ws = water or sludge to be added in gallons. The other variahk-. IIH defined previously. All biochemical conversion processes (such as composting) are

- 74. ill i' I~I, two-step operations. The first step is the decomposition of complex mohr nh waste materials into simpler entities. If there is no nitrogen available, 111I'1 I full extent of the process. If nitrogen is available, however, the second SII'PI synthesis of the breakdown products into new cells. These new microonuu 1 contribute to the process, and the system operates in balance. Because of the high rate of microbial activity, a large supply of nillll}llll required by the bacteria. If the reaction were slower, the nitrogen could be li'i,,1 but since many reactions are occurring concurrently, a sufficient nitrogen S'IIII" necessary. The requirement for nitrogen can be expressed as the C/N ratio, ,,;.,111'1, II A C/N of 20: 1 is the ratio at which nitrogen is not limiting the rate 01 lil'I lit position. Above a C/N of 80: 1, thermophilic composting cannot occur, bCI.11I~III nitrogen severely limits the rate of decomposition. Most

- 75. systems operate 111'11 these extremes. Some researchers recommend an optimal CjN ratio of )'1 I " C/N ratio higher than this can increase the time to maturity. Nitrogen can IlI'l'''" limiting at a C/N ratio greater than about 40: 1. I 5 At higher pH levels, the I Ii11111 I will be lost into the atmosphere as ammonia gas if the CjN ratio exceeds 1'1 I 1('('ll'.1 l' , '/1 Table 6-4 Carbon/Nitrogen Ratios for Various Materials C/N ----_._-------_._-------_ .._-_._----------_._-_._-_ .._- Food waste Raleigh, NC Louisville, KY MSW (including garbage)

- 76. Berkeley, CA Savannah, GA Johnson City, TN Raleigh, NC Chandler, AZ Sewage sludge Waste activated Mixed digested Wood (pine) Paper Grass Leaves Sawdust 15.4 14.9 33.8 38.5 80 57.5 65.8

- 77. 6.3 15.7 723 173 20 40-80 511 Source: [15] fus and lev I. POI' 'dllt-"II )11,11 I IIII)(). ,'., IIII' Pillf II 1111 III II IIHII '111111'1.111111 II I post pile an be I' -ndll I 'nH I1HII,lI('d il l.rl ( 111101 ,II • ,lpp.lI'tIlli ,II The pH also t ('~ ts nil I' gcn Ii S , IWi,III (' 111111011111 (NIII) '(,IP' ,I 11111111 nium hydroxide is form d ab v a I II vnlue 01 7,(), will I k lll1pO I' "I

- 78. and gaseous NH . Thus, ffi ient 011 p st IP 'l'tllloIlS,which ( lel'illi' ,101111.1 I3 _ of 8.0, cannot retain nitrogen at a great I' 01 -ntrnrion than C/N 01 .Ihl HII I I The time required for a compost pil I rnatur , d I -nds 011 811I1111111111 the putrescence of the feed, the insulation and (CI'(lion I I' vidcd, lire (/11 I the particle size, and other conditions. Usually, tw w ks is onsid 'I'cd II" II I mum time for the adequate composting of shredd d rnuni ipal I"('IIM'ill II rows. Mechanical compo sting plants, using inoculation of previously (111111111 I materials, can accomplish decomposition in 2 or 3 days. This mat I'inl Is 'I 11111 active, however, and usually requires further stabilization. 12 The completion of composting is judged primarily on the b sis 01.1 II drop in temperature and a dark brown color. A more accurate 111(':181111 I I determination of starch concentration in the compost. Starch is readily (('1111111

- 79. able, and thus, its disappearance is a good indicator of mature compost. A "II laboratory method for measuring starch in compost is available, although II " I nique yields only qualitative information.v" This technique also can Iw ,IPI'III II a composting demonstration project for the classroom." A more rigorous 1111 I 1 of the end point is the drop in the C/N ratio to perhaps 12: l. High I' C/N I III will result in continued decomposition of the compost after it is applied, .1111111 subsequent robbing of nitrogen from the soil. Recognizing the difficulties involved in the processing of a hetci (lf',1 III I material such as municipal solid waste, Colueke" suggests that the viabilirv III II biochemical process be judged on the basis of the organisms employed. 1{1'f1,lldl of what biochemical process is used. the organisms should have the 11111" I characteristics: Not Fastidious. They will work under adverse conditions (e.g.,

- 80. wid temperature range) and be tolerant of environmental change. Ubiquitous. They should exist in nature. since pure stock cultures degenerate with time and rarely stay pure. Persistent. They must grow in the environment without special assistant I' Not Picky. They should be able to use a broad spectrum of substrates If these criteria are used to judge the efficacy of composting, the [11111 would pass with flying colors. Composting is able to handle many organii W I I and seems to be insensitive to changes in flow rates and feed characteristic s 1111 a purely fundamental and biochemical perspective, composting makes a gt,,11 II of sense. However, it is important not to forget the old saying: "Garbage in. g,1I1 1 I out." Thus what is being composted is very important. 6-2-2 Composting Organic Waste The organic fraction of MSW can be composted, and the products from II

- 81. facilities may have significant environmental and cash value. Organic WII are now composted in thousands of communities throughout the Willi I 1111111(', 1 :,"1,111,1. (lYI'1 1,111 01 II(' 111111 .1"lId I'HI lililll' 11, ()III(' /01111 IIII'll I III,'''' 111111' )HIII~ Oil U mU111 lpnl /iud(' 1111 11111 flillpil 111'd PI') css. At ils /iill- III vcly aerated ompost s ,1('11 (1111 I III III'tll'l ,11 II r s r 11 I 11.11,1'( I'g, ni wast pi cd 111 II "I P 111111'1 I II S, all d windr ws. ,II I will Ir( ws ar laid in I 1115 lOWS 01 ,tI~()lIt II I) rt (1.2 to 2 m) high 1111 I (I), Moistur content is maintained 11 far 1:0% by adding water and/ r I, I ,I II'C I d. B cause the reaction is r bi , oxygen must be made avail- I II III' mi r rganisms, and this is done by turning the pile with

- 82. a specially 1111111, d agitator (Figure 6-7). While this is the least expensive and simplest t'" III 01 ornposting, it is not always used. Other factors such as regulations, I Jllllhl'rn. pace availability. organic waste composition. and climate (rain. III d's rl) may require different composting methods. , 11101' sophisticated system uses an actively aerated system. Windrows fllllilt I 11 top of perforated rvc pipes (Figure 6-8) or concrete floors 1111 ( () with an air distribution system and air blowers for forced aeration. 1111 j- La and 6-11). Instead of turning the windrow periodically to aerate the "rlIIIW, c ir is forced through the windrows. The air blowers supplying the air Itl' rontinuous or intermittent. Enough air must be supplied to support the Ilrli mposting. Without enough oxygen. the pile will become

- 83. anaerobic and I I 11101' problems. On the other hand. too much air will cool the pile and stop 1I111l1 ting activity. - - ------------ tire 6-6 Windrow composting system. (Courtesy William A. Worrell) I ~ •• ~ •• •• •• •• 8 Perforated pipe for air distribution. (Courtesy William A. Worrell) 6 9 Air distribution channels. (Courtesy William A. Worrell)

- 84. Mobile aerator for windrows. (Courtesy William A. Worrell) Figure 6-10 Air blowers for an aerated static pile. (Courtesy William A Worr II) Figure 6-11 Air blowers for a covered indoor aerated static pile. (Courtesy Willidlll A Worrell) It 111'IH'I.ltl'd, I,ll t'l k I o III 110, I "1- III 111,111111 1111 I II Il' l lnto III 'will I 1111' 1'111Is '''I' II" 110 ,IS 11 n '1"1 VI'.t II 1I1I1 , utu, lilli' all' is blown lnro IlIdlOW, III 'I) it Is, I sitivc aer.ulun 1111 P. I" III 'Ib I h S advanu g s II Ililv,lllllg'S, with 11 ativc 11'1,1111111 11'111, Ill' ,11' passing through Ill' I I lit Il' I int 111 pip at th bouom 01 till' II I 'by T '< Linga vacuum. This air 11111111 1 'dis harg d into an air tr '(1111 'Ill sy L'In, su b as

- 85. a biofilter or scrub- I 1IIIItlilimiz dors. However, a n I( rive t 'r Lionsystem uses more power and I 1IIIomi t the compost pile. Th bigg st disadvantage of a positive aeration It iii I III l the air is blown through the pile and exits into the atmospher . I IIIIolSe r not controlled. To control odors a layer of finished compost or a utili II v r can be placed on top of the pile. Thus the air must pass through 111'1'1, whi h will remove some odors (see Figure 6-12). I Hll'r ptions provide even more control of the compost process. I I .uupl , the aerated composting may be done under a permanent roof (see III (I I ), which prevents run-off from rain during the compo sting operation. 1111 IIII option is to compost inside a building (see Figure 6- 14) so that there will 1111 11111- ff and air can be collected and treated. Finally, aerated composting

- 86. II III d)11 inside fully enclosed tunnels (see Figure 6-15) for the highest level of 1 11111 or t mperature, moisture, and odor. 1'1' bic decomposition results in a dark brown earthy-smelling material that IIIWnutrient value but is an excellent soil conditioner. I, ure 6-12 Plastic cover on a windrow compost pile. (Courtesy William A Worrell) • /s ill (OlIljlo, I 1ll,1I1lilil't'IIIII'd /111111~/ W / ' 11t sign iII n III I LI bIi h(."1/ ill ')1 ' I (Ill( I d N I, (,111/ (' ,II II J ( , « (JII( 1'111. 1,(',1 /, 0" 'xt1mpl', I, I II 00 I J m 111 mp SI mil / ' 1'10111MSW J WI / gned, however, the econon in' I '/ ,':, '. n 1111( sl/nll I" I 1 of compost. ( 11.1ys. IIIVAII,bly lJl lud s : / 101 I II II Whil.e there may be some advantage to usin mixed

- 87. mdfilhng or incineration it will big. wast OlllpCl 1111 . For example, if regulati~ns p~eve~tc:; ia~~~l~~ mos; like.'y I,.iv('11hI I I - be necessary to compost the waste be .. 1 lmg 0 unn <II' / WoIlli I Th erore It IS andfilled e ~econd problem, the limited reduction in the v . techlllcal sOlutions because th olum (W,II"I II e process can be cha d / IS such as glass metals and I f nge I a Ill" I I II" , r so on n act com ti ;:>lyanother process within a com Iete '. pos Ing may b' '1111 iii ~ process has been run to prod p mat~nals recovery planr, ()111 /"1 .iesh) of the light fraction of ~cela p~fitresCIble material from IllI' II, 1/1 air-c aSSI led refuse 20 Thi . % of the raw refuse and contained 740 . . .IS mal 1'1.1111111I -y the material was digested for methane Yo v~latI.le s~hds.

- 88. Allho(IH/' III I .posted. pro ucuon, It also all III III I II The fraction of putrescible material in refu h . ~ears and will no doubt conti d se as been s~eadJ/y (/('( /111/111 :ompostable fraction Similarlyn~e to 0 ~o: ~s the organic fracliOIl i,,1III/II 3e could ever be recovered as co;::P~s an It IS un!j~ely that more liI,III 'llIll ~ normal means, and this cost mu; b t. ~~e ~emalhlllng 50% must Iw iii ",, .aciliry e a e to t e total cost of 1111'~111111" The last problem is mostly one of odor d . ot that the odor from compost '1 . 1pro ucuon. Although 1>01111/'1,1 : minority. Compost plants do pi eSllls Pheasa.nt, these people arc ill Ihl sme -t ere IS no do bt f h ;:>lants must be located fairly far fr identi u .0 t a!- ,lIld 1111 :her cost-transportation. om resi entia I areas. ThIS requir~'I1I1'''' "'

- 89. MSW composting plants are id . . lot sell the compost '1'( must pal. a tipping fee to accept MSW. II 1111/" r contmue to accept . . sh flow. This results in an ever l' . '1 mcommg MSW I() Ilid/IlI . - ncreasmg pI e of c . ds, It eventually is too big to be turn d . ompost on-SIte. ;, II1I /' :-problems. e , and It becomes anaerobl(, I d" I In conclusion, it seems unlike! that . d ge scale, at least in more developYed mIXe. waste composting willIX'II I Ii . . countnes Wheneve . mUlllCIpal scale is suggested the d " 'k r <omposung II/ " '" 1ismal record of past mixed ~ t ecisron ~a ers should always bea: "' 111111 : under an aura of optimism anadse ctohm~ostmg efforts. All of these pl.uu- . en usrasrn and all f th .nised Success The engineer and d " ' 0

- 90. e economt. 0111.11, ae proposed new com ost la eCISlOn maker should ask what is so dll/III .rs have failed. p p nt that would allow it to succeed whih- .tI/11 While composting MSW presents man r bl . {Shas real benefit Bioremedl'au'o b Y Pdo ems, compostmg of SOliII " . n can e use to tre t .I d nated with oil and other petroleum roducts 1 a SOl an ~~undWoll.'I' "" as bacteria, use contaminants as p f ~so vents, and pesticide- M IIIII" . . a source 0 rood and e Th dposting in cleaning up the cont . . nergy. e a V<lIlLIIlI~I ammatlOn seems well established.28 'II 1111 Iypl' 01 IHIiI I, .11 .111(1,III I H/IIII I I II 1111II rl, A (0 IIII l'lIlllo11 1111h n, 1l.lwdllll Ilild I/Ili 1111 11/11 ,I III ('riOI' C )111110111,high 1111111'011'11 /11"1{" I'OIll II 'w~g II' atrnc nt p/IIIII /11 I' 1"111 II 1'1 I' I' I11fny y ('S is

- 91. I 1I/II11tl'j 'l1iS in OJ I osting." '1'111'pI(IIII"111will «(11111osting slud always 111111Iilat lh s liels. ornpa I 100 ligitll , '(..-Iv"B II() sl ( s for air to en! r I'll. 'I'/Iis pr bl In can be solved h ml III! tll{' sill Ig with wood chips and 1'1 I Ilf the mixture. The woo I hi] II fin.' ornp S d f poorly decomposable III., I ,11(/ lignin and can be readily I' rn v eI from the stabilized material 11111'11,(,I' ning and then can be reused. Raw sludges can be composted to a (I I oil nditioner or a high-grade topsoil. I ',ld I ,111I I I, INAL THOUGHTS II11II W rking for municipalities-either directly or indirectly- must have •• ill'! I' f autonomy. Professionals correctly believe that professional auton-

- 92. , 11'11.f ial to the welfare of the public. If the government starts telling phy- III/lOW L treat people, telling preachers what to preach, or telling engineers II /Ilil I things, then the public loses. Accordingly, these professions have "III 1 gll rded their autonomy in the name of the public good. The engineering II (III r ognizes that, if engineering is to maintain its professional autonomy, 1'11111/has to trust engineers, and it is very much to the advantage of engineer- Ilid Ih public at large to maintain this trust. lilt" autonomy can be taken away by the state, of course, as witnessed in 111 that have totalitarian governments (such as the former Soviet Union) in "IJII -proud and independent engineers became tools of the communist , HlIlI( ru and had little say in technical decisions. The inability of those engi-

- 93. I Ii vie their concerns about projects that were counterproductive, wasteful II 11111's. and harmful to the public was in great part responsible for the even- I d"wn(alJ of the Soviet empire." 1111ln ers, as all other professionals, must work to maintain public trust. III11m te trust in the engineering profession, professional engineering II I, h ve all drafted statements that express the values and aspirations of the II (n-statements commonly referred to as a "Code of Ethics." ),, of the earliest codes of ethics in the United States was adopted in 1914 1111AI11 rican Society of Civil Engineers (ASCE). Based in spirit on the original It III Harnmurabi."? the 1914 ASCE Code addressed the interactions between lilli'S and their clients and among engineers themselves. Only in the 1963

- 94. I '11h did the ASCE Code include statements about the engineer's responsibility Ilu I .neral public, stating as a fundamental canon the engineer's responsibility ,1111 health, safety, and welfare of the public. 11 I 97, ASCE modified its code to include the commitment of engineers to 11111.11Ie development. The term sustainable development was first popularized llil W rld Commission on Environment and Development (also known as the 111111111,nd Commission), which is sponsored by the United Nations. Within this 1"111,. ustainable development is defined as /I development that meets the needs M rals ill «)lllpO ( 1",IIIIIr.(1111('1I110111~L W, h 1011(1,1(,1,1111)(' ,I( It present signif ant I nbl: "l'nlill (' jlH 1'111,I I. ',Id, I(}t • 111111', I 1" III level of 800 pprn in mp Sl!TIt I' /'10111M,'W,i~ WIl('11 (

- 95. )mjlo, 11111,.1 designed, however, th onomi analyslr Inv,III,11 I in lu I •. a plnl I II sale of compost. While there may be some advantag l using mix xl WeSI' 011'1"1 III to landfilling or incineration, it will be costly nd i !TI st lik ly ddYl''' " tion. For example, if regulations prevent the landfilling r UJ u • I '<I WII h may be necessary to compost the waste before it is landfill d. The second problem, the limited reduction in the velum of' W.I II has technical solutions because the process can be changed I iH IlI,d I items such as glass, metals, and so on. In fact, composting may Ill' 11111 simply another process within a complete materials recovery pl;1111 (It I scale process has been run to produce a putrescible material Ir 111(III I (7-mesh) of the light fraction of air-classified refuse." This rnt t '11.1111111

- 96. of 6% of the raw refuse and contained 74% volatile solids. AIIIH)II}," I" study the material was digested for methane production, it also ould III I composted. The fraction of putrescible material in refuse has been steadily t(o,llllill the years and will no doubt continue to do so. As the organic fra tiou I I I the compostable fraction similarly drops, and it is unlikely that more 111.111II refuse could ever be recovered as compost. The remaining 50% must III' "I I of by normal means, and this cost must be added to the total cost of"II,.' 1111I ing facility. The last problem is mostly one of odor production. Although SPIIiI I' insist that the odor from compost piles is pleasant, these people are III III tinct minority. Compost plants do smell-there is no doubt of that ,11111 the plants must be located fairly far from residential areas. This

- 97. requiu-uuut another cost-transportation. MSW composting plants are paid a tipping fee to accept MSW. II Iii II cannot sell the compost, it must continue to accept incoming MSW 10 III III a cash flow. This results in an ever-increasing pile of compost on-site. i III builds, it eventually is too big to be turned, and it becomes anaerohn , I II odor problems. In conclusion, it seems unlikely that mixed waste composting will ls- II a large scale, at least in more developed countries. Whenever compostinj; 1111 on a municipal scale is suggested, the decision makers should always 1)(,,11II I the dismal record of past mixed waste composting efforts. All of these pili III built under an aura of optimism and enthusiasm, and all of the econorn i. 1111I promised success. The engineer and decision maker should ask what is so II "

- 98. in the proposed new compost plant that would allow it to succeed wlul. 1111 others have failed. While composting MSW presents many problems, composting of Sill" stocks has real benefit. Bioremediation can be used to treat soil and groundw.tu i taminated with oil and other petroleum products, solvents, and pesticides. tvl I II such as bacteria, use contaminants as a source of food and energy. The adv.inhu composting in cleaning up the contamination seems well established." 11111 (II' III ,,1111111.110111I III ill 1111111II 1 I " II d, A tOlllhllltllloll ,~I(h II ,.Iwdll II .llId 111111'11 III 1 Iii '1'101(OlliPOSI,hlgh III 1111°11'11 lutlll /'1'0111scwngc 1"'<11111'111plill" 1111• 1)'1'11 II' Ili)l' many years as 1!lIIIIII'1'I1(S in ornp sling.i"'I'Ile Pllll,II'11 Wilt (Oml ostlng sludg always 1111III 11 the s lids mpa I 10 I Ii ilil , k,wlnll 110 spa s ~ r air l

- 99. nt r ,,,. III, problem an b solved by nilx 11/(Ill' sludg with wood hi] S (In I 1IIIIIf III' m ixtur . The wood hi] s arc ornp s d of poorly decomposabl I,I I ,iiI I lignin and can be readily I" IT) V d from the stabilized mat rial IIjilt 'I' 'ning and then can be r us d. Raw sludges can be composte I l a I" () I onditioner or a high-grade topsoil. 1'0111 .Ill,! I', INAL THOUGHTS "'1 W rking for municipalities-either directly or indirectly-must hay ". II " f autonomy. Professionals correctly believe that professional auton- , 111'11fI ial to the welfare of the public. If the government starts telling phy- I I uw l treat people, telling preachers what to preach, or telling

- 100. engine rs ItI III j lei things, then the public loses. Accordingly, these professions hay II I f II, rdeel their autonomy in the name of the public good. The engineering 1111r ognizes that, if engineering is to maintain its professional autonomy, ulrl hs to trust engineers, and it is very much to the advantage of engineer- lid (ill public at large to maintain this trust. III" c U tonomy can be taken away by the state, of course, as witnessed in III III l have totalitarian governments (such as the former Soviet Union) in II 1111 -proud and independent engineers became tools of the communist 1I1I1!Pllland had little say in technical decisions. The inability of those engi- III v ice their concerns about projects that were counterproductive, wasteful 11111 ,and harmful to the public was in great part responsible for the even- IIIIV 11 rail of the Soviet empire."

- 101. 11Iflneers, as all other professionals, must work to maintain public trust. 1111111te trust in the engineering profession, professional engineering I It' h, ve all drafted statements that express the values and aspirations of the on-statements commonly referred to as a "Code of Ethics." I "Il' of the earliest codes of ethics in the United States was adopted in 1914 1 merican Society of Civil Engineers (ASCE). Based in spirit on the original III l lammurabi,"? the 1914 ASCE Code addressed the interactions between II liS and their clients and among engineers themselves. Only in the 1963 ItIII did the ASCE Code include statements about the engineer's responsibility -neral public, stating as a fundamental canon the engineer's responsibility III II alth, safety, and welfare of the public. III (997, ASCE modified its code to include the commitment of

- 102. engineers to 111,11Ie development. The term sustainable development was first popularized World Commission on Environment and Development (also known as the 1II.Ind Commission), which is sponsored by the United Nations. Within this II, sustainable development is defined as "development that meets the needs o lh I I' 'S '111with Lit 01111'1' mislllK 1I1t'.1I I ( (f' futur ('11 '1',Hlt)!!. II) 11111 own needs. II/It ustainable cI v J I J)I 'Ill ( 111II,' I, r II xl in tI 11uI1lb'I' or W,I / indeed the Brundtland Report itself in lud .. I'll IIf 'I' nt I 1I1ilioil III report for the United Kingdom Departrn nt 111' Envir nrn nt 111.1II II1I pages of definitions." Although the original purpose of introducing the idea of susrn i

- 103. 11,11d d opment was to recognize the rights of the developing nations ill 11'1111 I resources, sustainable development has gained a wider meaning and 11I)W111II educational needs and cultural activities, as well as health, justi c. I" 1,1 security." All of these are possible if the global ecosystem is to nli)llI, II! port the human species. We owe it to future generations, therefor, 1101III Ii the earth they will occupy. Using biological processes to produce usclul I'HIII such as methane and recovery nutrients is increasing. We recogniz Ih,11III II non renewable fossil fuels for our energy use is not in keeping wi th IIII' I" It I of sustainable development and contributes to the impact of gl'<:('1I11I11I Composting also contributes to nutrient recovery. For example, ph splu n III valuable limited resource and should be reused for agricultural appl h ,II lilt not lost in landfills.

- 104. References l. Alter, H. 1989. "The Origins of Municipal Solid Waste: The Relationship Between Residues from Packaging Materials and Food." Waste Management and Research 7:lO3-114. 2. Bell, 1. M. 1964. "Characteristics of Municipal Refuse." Proceedings National Conference on Solid Waste Research, American Public Works Association, February. 3. Pfeffer, J. T. 1974. Reclamation of Energy from Organic Refuse. 670/2-74-016. Cincinnati, Ohio. 4. Pfeffer, 1. T. and J. C. Liebman. 1976. "Energy from Refuse by Bioconversion Fermentation and Residue Disposal Processes." Resource Recovery and Conservation 1:295. 5. Hagerty, D. J., 1. L. Pavoni, and 1. E. Heer.

- 105. 1973. Solid Waste Management. New York: Van Nostrand Reinhold Co. 6. Vesilind, P. A. 1979. Treatment and Disposal of Wastewater Sludge. Ann Arbor, Michigan: Ann Arbor Science Publishers. 7. Lawrence, A. W. and P. L. M (,.111 I I "The Role of Sulfide in Pl'eV('11111I1 Heavy Metal Toxicity in An,H'lIIhli Treatment." Journal of the WIII"1 Pollution Control Federation ~'I I I I 8. Pfeffer, J. T. 1974. "Temperature I 1111 on Anaerobic Fermentation (,f Domestic Refuse." Biotech1/()lu,~,'111I/ Bioengineering 16:77. 9. Hille, S. J. 1975. Anaerobic D(,('/IPI/ of Solid Waste and Sewage SIIit/S" to Methane. EPA OSWMP SW I 'I Washington, D.C. io. Monteith, H. D. and J. P. Steplu-n II,

- 106. 1997. "Mixing Efficiencies ill Full-scale Anaerobic Digesters I,, Tracer Methods." Proceedings Symposium on Sludge Trearuu III Waste-water Technology Ccnru-, Burlington, Ontario/ Canada 11. Bowerman, F. 1979. "Methane (,1'1111 from Deep Landfills." Proceedlll," Engineering Foundation COllk11 III on Resource Recovery, Hennikr-r, New Hampshire (July). I I ,. I()'I ('IlI/IIIII~'I/I, 1i.11I111,11II• ,It • / II It (I J , 1'1111/IVIIiI I: I{(i I 11'1'11' I III , III I ' II (I ,"jl,llil 11l'll SIIV v.il ln " , I II / 11111111)till Munl II 11Wa,I", /01111111 111'1 I'ollutlon ;onll')1 P' I'mll n I I(), I 1)1) I 11/1111 W an I It A. Nc rdSl' l. I ,II I'" , /I

- 107. /1,1'(.11'II ~ r Vi r I W st '011"11)Sllllg. 11/" 'I1I'1c' ,n. : 0-61:. t , It 1t'1', " I 7 ." te t f th Art.o II Iunv 'rsi n I I' ess ." vroce d".,p,s I1II uc ring Ii undati n nf I' n ' 111Ill'H UI' R v ry, Rindg r 'W II, mpshir (July). " /It/lysis oj omposti~g as an. I I II 11//011mental Remeduuion Technoiog) . II I 1-. 1;1A 530-R-98-008. I II I, P. A. 1973. "A Laboratory I I' Is in Composting." Compost 1,11111e (September-October). . " 1 1 R 0 1971. "Compost Studies.II I, . . . I tllllpOt Science (March-Apnl). I I nd, P. A. 1973. Solid Waste IIl,qineering Laboratory Manual. DU.r1:arn, Nt rth Carolina: Department of CIVil III ineering, Duke University. I, L F F Kurz and G. J. Trezek. 1976.II ,II'., . .,. , f