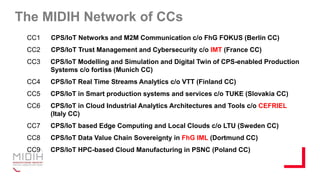

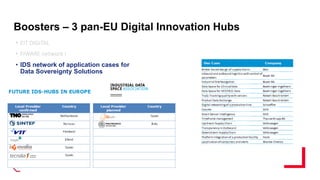

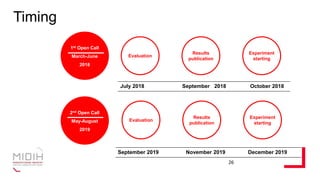

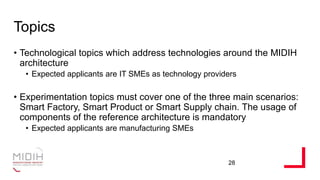

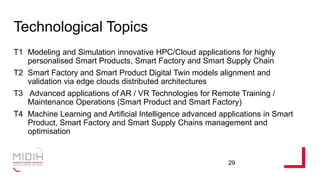

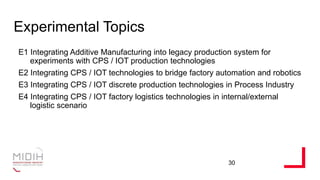

MIDIH is a 36-month, €8.5M project coordinated by EIT Digital to establish a network of digital innovation hubs across Europe to support manufacturers, especially SMEs, in their adoption of Industry 4.0 technologies. The project aims to provide open digital platforms, technological and business services, and skills training to help European manufacturers digitize their operations and remain competitive globally. MIDIH will launch two open calls offering up to €60K in funding per project for experiments utilizing its reference architecture and involving smart factory, product, and supply chain scenarios. The first call will run from March-June 2018 with funding decisions in July 2018.