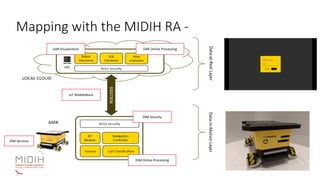

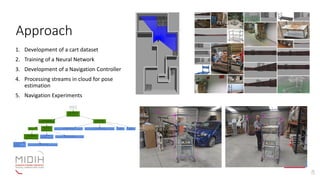

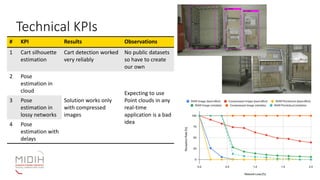

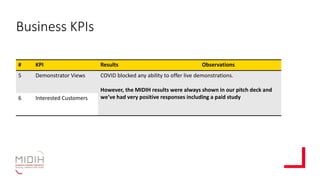

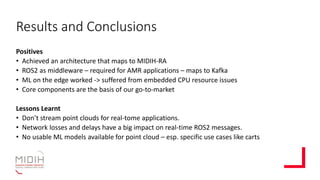

Tractonomy Robotics, based in Belgium, develops next-generation autonomous mobile robots aimed at improving material cart handling in intralogistics, addressing the challenges of existing manual and outdated automated systems. Their robots feature advanced AI-powered navigation, can tow up to 650kg, and are supported by a cloud-based maintenance service to ensure zero downtime operations. The project has achieved notable technical milestones but encountered challenges such as network delays and limited available datasets for machine learning applications.