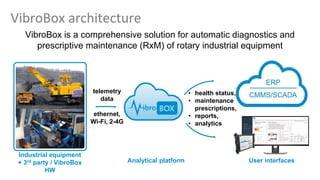

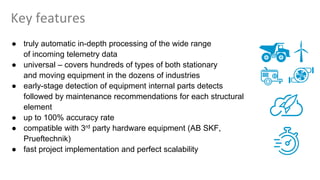

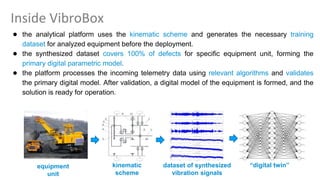

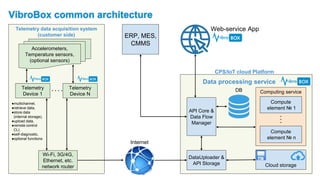

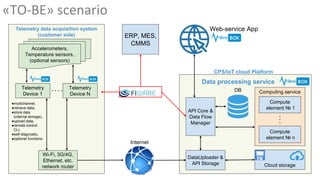

Vibrobox, developed by Sitel LLC, offers an advanced solution for automatic diagnostics and prescriptive maintenance of industrial equipment, utilizing cutting-edge technologies such as AI and digital signal processing. The system is designed for both critical and mass-market equipment, featuring high accuracy, scalability, and rapid project implementation. Key benefits include reducing unplanned downtime by 15%, lowering maintenance costs, and supporting the digitalization trend in industries.