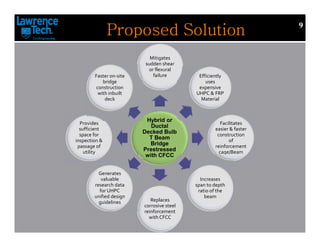

The document summarizes Ranjit Kumar Sharma's thesis defense on the structural behavior of hybrid and ductal decked bulb T beams prestressed with carbon fiber composite cables (CFCC). The experimental program involved shear and flexural testing of hybrid and ductal beams with varying shear span-to-depth ratios. Research findings showed the beams failed in diagonal shear or flexural compression. Crack patterns and load-deflection responses are presented. The research aims to examine shear behavior without stirrups and evaluate design guidelines for hybrid and ductal beams.

![36.5%

HB-100-3-0SS

38.5%

HB-100-4-0SS

31.9%

HB-100-5-0SS

27.2%

HB-100-6-0

0

10

20

30

40

50

60

70

0

10

20

30

40

50

60

70

Ductility Ratio (%) = [Ei/(Ei+Ee)]

DuctilityRatio(%)=[Ei/(Ei+Ee)]

DuctilityRatio(%)=[Ei/(Ei+Ee)]

Beams

37

LMT

(Deflection)

Load

Shear

Force

<69%

70%-

74%

>75%

Ductility

Ratio

Brittle

Semi-

Ductile

Ductile

Failure

Mode

Results/Hybrid Beam Shear Test:Results/Hybrid Beam Shear Test:Results/Hybrid Beam Shear Test:Results/Hybrid Beam Shear Test:

Ductility RatioDuctility RatioDuctility RatioDuctility Ratio](https://image.slidesharecdn.com/82c6319d-4cfe-4ef1-85c8-15b37e74ec90-161013021405/85/Print_Reduced-37-320.jpg)

![60.31%

DB-132-3-0ES 56.48%

DB-132-4-0ES

0

20

40

60

80

100

0

20

40

60

80

100

5

DuctilityRatio(%)=[Ei/(Ei+Ee)]

DuctilityRatio(%)=[Ei/(Ei+Ee)]

Beams

48

<69%

70%-

74%

>75%

Ductility

Ratio

Brittle

Semi-

Ductile

Ductile

Failure

Mode

LMT

(Deflection)

Load

Shear

Force

Results/Ductal Beam Shear Test:Results/Ductal Beam Shear Test:Results/Ductal Beam Shear Test:Results/Ductal Beam Shear Test:

Ductility RatioDuctility RatioDuctility RatioDuctility Ratio](https://image.slidesharecdn.com/82c6319d-4cfe-4ef1-85c8-15b37e74ec90-161013021405/85/Print_Reduced-48-320.jpg)

![HB-100-3-0SS

SS-100-3-6*

SC-100-3-6*

HB-100-4-0SS

SS-100-4-6*

SC-100-4-6*

HB-100-5-0SS

SS-100-5-6*

SC-100-5-6*

HB-100-6-0

SS-100-6-6*

SC-100-6-6*

0

10

20

30

40

50

60

70

0

10

20

30

40

50

60

70

Ductility Ratio (%) = [Ei/(Ei+Ee)]

DuctilityRatio(%)=[Ei/(Ei+Ee)]

DuctilityRatio(%)=[Ei/(Ei+Ee)]

Beams

57

LMT

(Deflection)

Load

Shear

Force

LMT

(Deflection)

Load

Shear

Force

<69%

70%-

74%

>75%

Ductility

Ratio

Brittle

Semi-

Ductile

Ductile

Failure

Mode

Comparison BetweenComparison BetweenComparison BetweenComparison Between Hybrid &Hybrid &Hybrid &Hybrid & HSCHSCHSCHSC Beam*Beam*Beam*Beam* TestedTestedTestedTested

inininin Shear: Ductility RatioShear: Ductility RatioShear: Ductility RatioShear: Ductility Ratio](https://image.slidesharecdn.com/82c6319d-4cfe-4ef1-85c8-15b37e74ec90-161013021405/85/Print_Reduced-57-320.jpg)

![66

Comparison Between Ductal & HSC Beam** TestedComparison Between Ductal & HSC Beam** TestedComparison Between Ductal & HSC Beam** TestedComparison Between Ductal & HSC Beam** Tested

in Flexure: Ductility Ratioin Flexure: Ductility Ratioin Flexure: Ductility Ratioin Flexure: Ductility Ratio

58.9%

HSC Beam**

59.3%

Ductal Beam

0

20

40

60

80

100

0

20

40

60

80

100

Ductility Ratio (%) = [Ei/(Ei+Ee)]

DuctilityRatio(%)

DuctilityRatio(%)

Beams

<69%70%-74%>75%

Ductility

Ratio

Brittle

Semi-

Ductile

Ductile

Failure

Mode

Applied Load

Displacement

Ductal or HSC

Beam**](https://image.slidesharecdn.com/82c6319d-4cfe-4ef1-85c8-15b37e74ec90-161013021405/85/Print_Reduced-66-320.jpg)