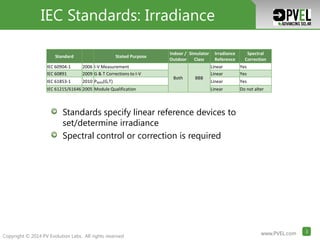

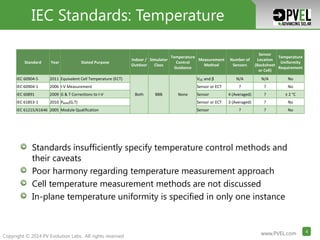

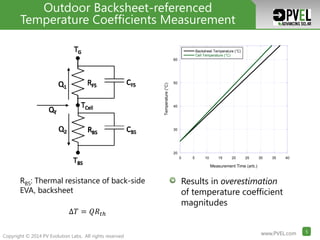

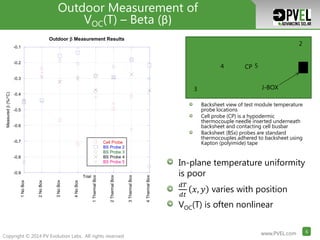

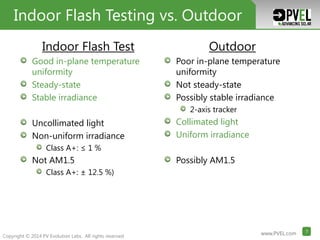

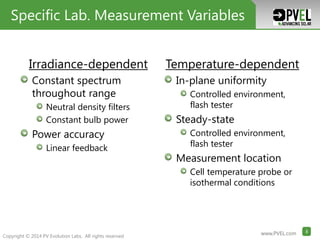

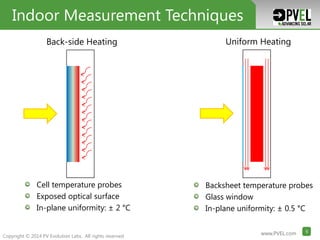

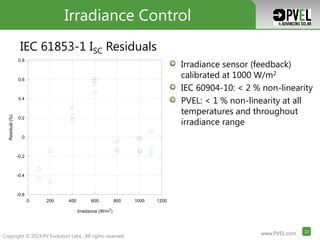

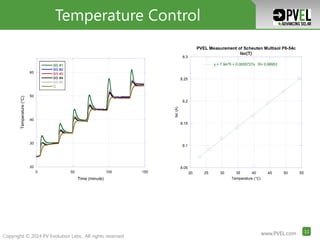

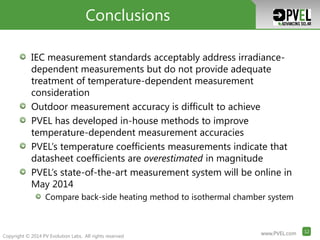

The document discusses the variability in performance measurements of photovoltaic (PV) modules, focusing on the inadequacies of existing IEC standards for temperature-dependent measurements. It highlights the differences between indoor and outdoor measurement techniques, the inconsistencies in temperature control, and the impact of irradiance on PV performance. PVEL indicates the necessity for improved methodologies to achieve accurate temperature coefficient measurements, which currently show overestimation in datasheets.