This document summarizes research on a nickel-chromium composite material reinforced with tungsten, aluminum, titanium, and molybdenum disulfide developed using powder metallurgy. Tests were conducted to analyze the material's high-temperature oxidation behavior and friction/wear performance. Results showed the oxidation kinetics followed a parabolic rate law, with oxide scales consisting of chromium oxide and nickel-chromium spinel. Friction decreased with increasing temperature up to 400°C, below which wear rate also decreased, but wear rate was highest at 600°C. The dominant wear mechanism at 600°C was oxidative wear.

![XUE: Ni-Cr-W-Al-Ti-MoS2 COMPOSITE 113

x2

= Kpt + C

Where x is the weight change per unit surface area, t

is the time and Kp is the parabolic growth rate

constant. There are two parabolic rate constants (Kp1

and Kp2) during oxidation period, indicating that

oxidation mechanism is changed, as shown in

Table 1, change time is 17 h at 800°C and 12 h at

900°C.

The Kp values for the Ni-Cr-W-Al-Ti-MoS2

composite was found to be 2.74 × 10-3

mg2

/cm-4

·h-1

before 17 h, then changed to a value of 0.59 × 10-3

mg2

·cm-4

·h-1

for the range 17-100 h at 800°C.

Similarly the various values of Kp for the composites

at 900°C were found to be 92.31 × 10-3

mg2

·cm-4

·h-1

for 0-12 h range and 40.91 × 10-3

mg2

/cm-4

·h-1

for the

rest of the exposure period.

It was proved that the oxidation mechanism from

surface reaction into the diffusion control, high

temperature is disadvantage to Cr3+

diffusion speed in

oxidation layer10

.

Constitution of oxidation film

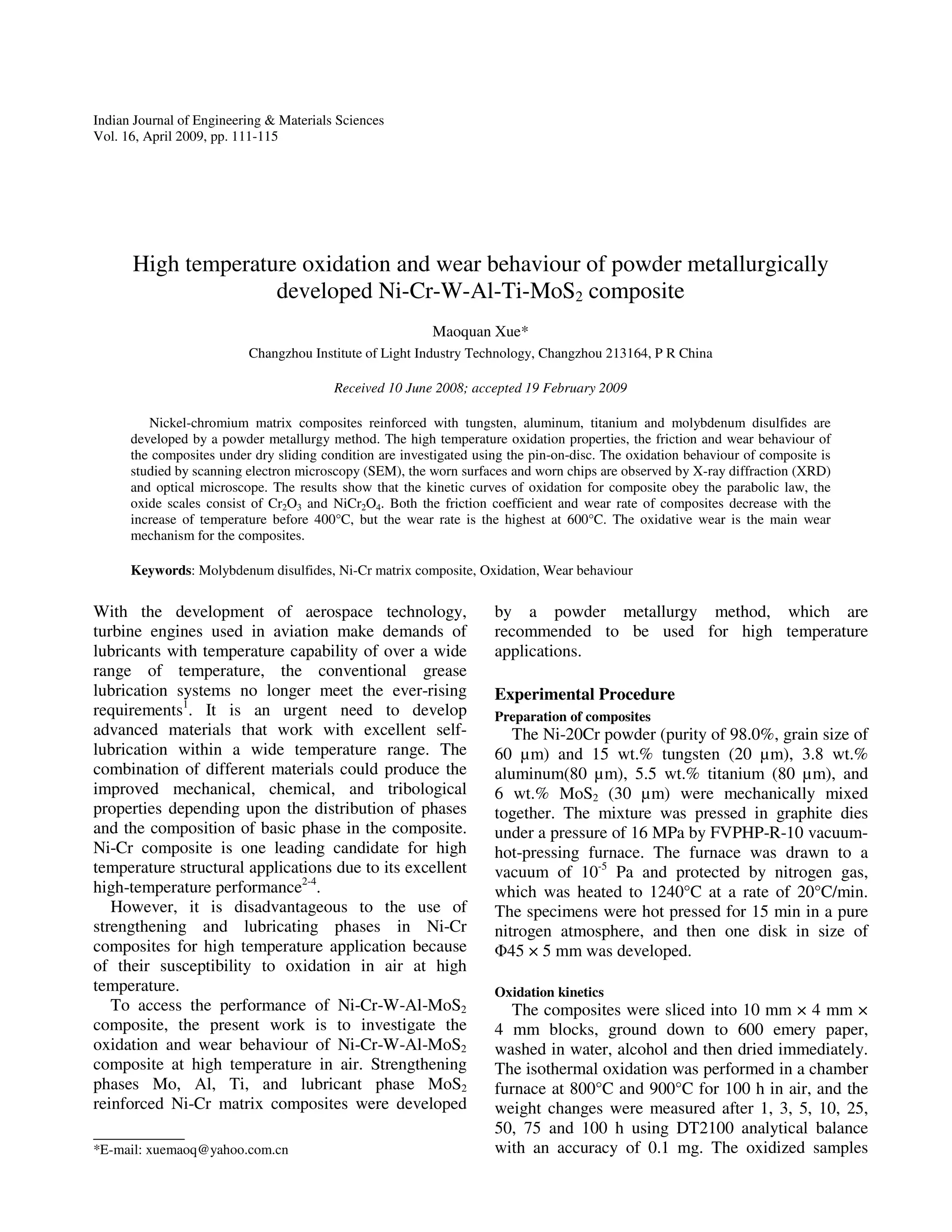

Figure 4 shows the surface morphologies of Ni-Cr-

W-Al-Ti-MoS2 composite after oxidation at 800°C

and 900°C for 100 h. It can be seen that the scale is

rather non-uniform, there are only a few acicular

oxides on the surface at 800°C instead of continuous

oxide films. A continuous scale was formed on the

surface of the composite at 900°C. After 100 h

oxidation at high temperature, the oxides on the

surface consist of Cr2O3 as well as NiCr2O4 spinelle

and TiO·TiO2 phase10,11

. The oxidation films on the

matrix firmly prevent the composite from oxidizing

further. The content of Cr2O3 has an increasing

tendency with oxidation time. After 12 h, the main

featured peaks of Cr2O3 form, which shows that the

oxidation film forms basically, consistent with the

results from oxidation dynamic tests. In the later

stage, oxidation process is mainly affected by Cr3+

diffusion. Though the dimension and magnitude of

NiCr2O4 spinelle increase with oxidation time, the

continuous films cannot form, which has no control

effect on oxidation velocity

Friction and wear behaviour

The friction coefficient of the Ni-Cr-W-Al-Ti-

MoS2 composite tested against the alumina ceramic

disk counterbody, with 100 N load and 0.8 m/s

velocity is shown in Fig. 5. It can be seen that the

friction coefficient decreases at elevated temperature.

At 200°C after an obvious slightly longe running-in

stage, the coefficient of friction became stable and

stayed at approximately 0.5. The friction coefficient

was less stable at a level of approximately 0.3 when

environment temperature was 400°C. The friction

coefficient at 600°C was stable and lower than 0.2.

Fig. 4—SEM observation on the surface of Ni-based composite oxidized for 100 h at different temperatures

Table 1— Parabolic reaction rate constants Kp and change time

at different temperatures of Ni-based composite

Sample B

Temperature

°C Kp1 [10-3

(mg2

·cm-4

·h-1

)]

Kp2 [10-3

(mg2

·cm-4

·h-1

)]

Change

time/h

800 2.74 0.59 17

900 92.31 40.91 12](https://image.slidesharecdn.com/2-220226111938/75/2-2009-oxid-20-cr-pm-800-900c-100hr-3-2048.jpg)