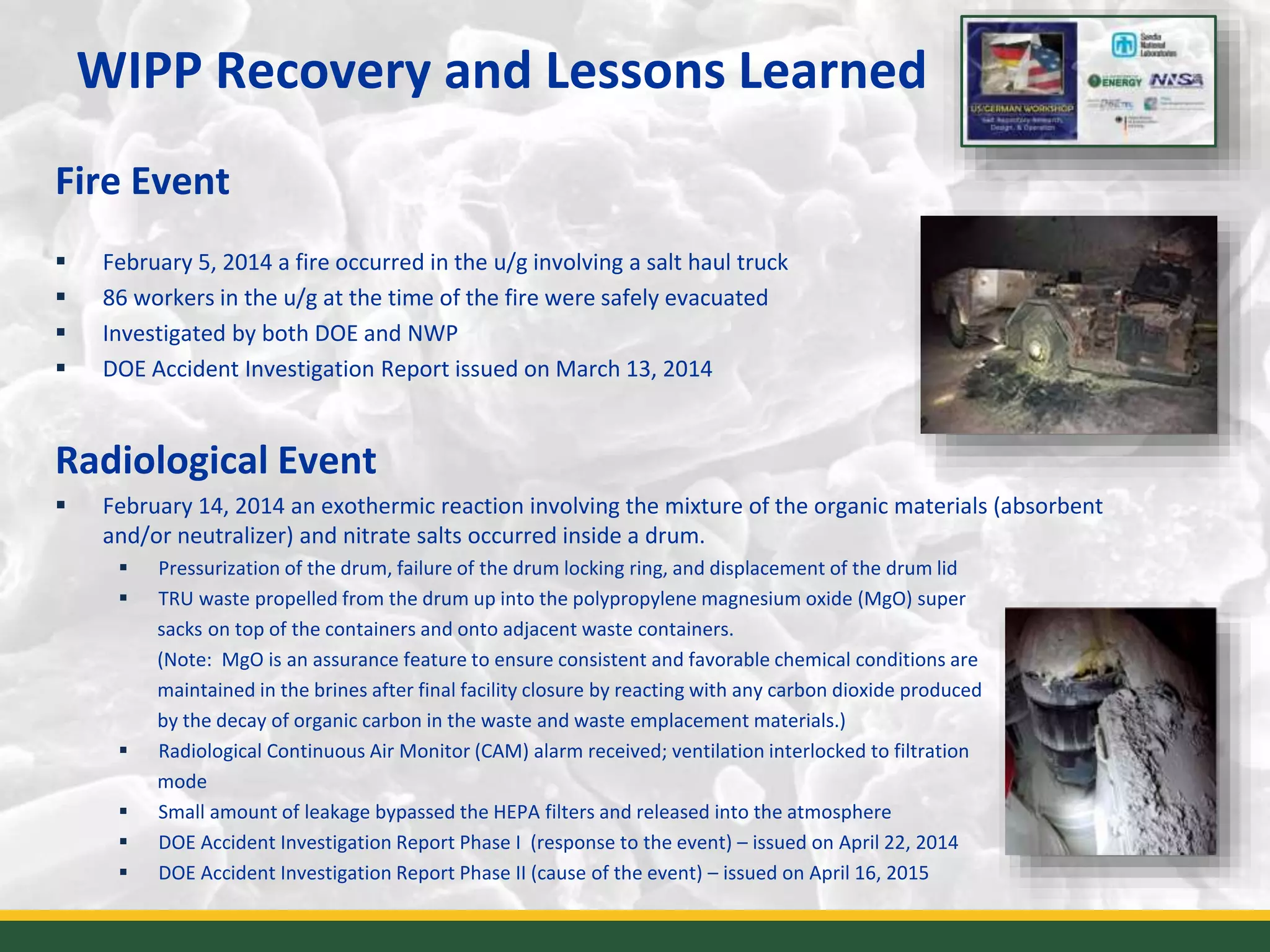

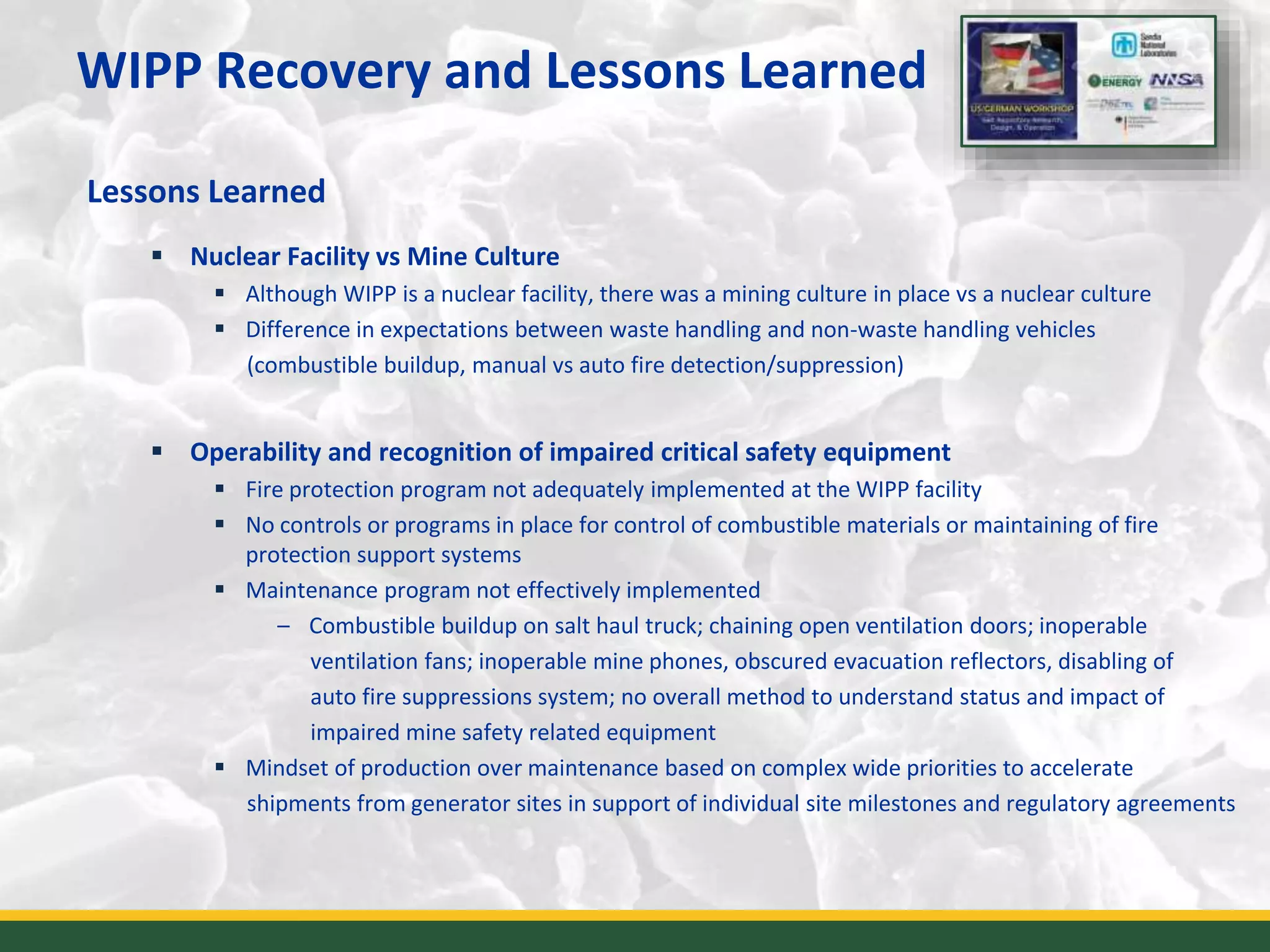

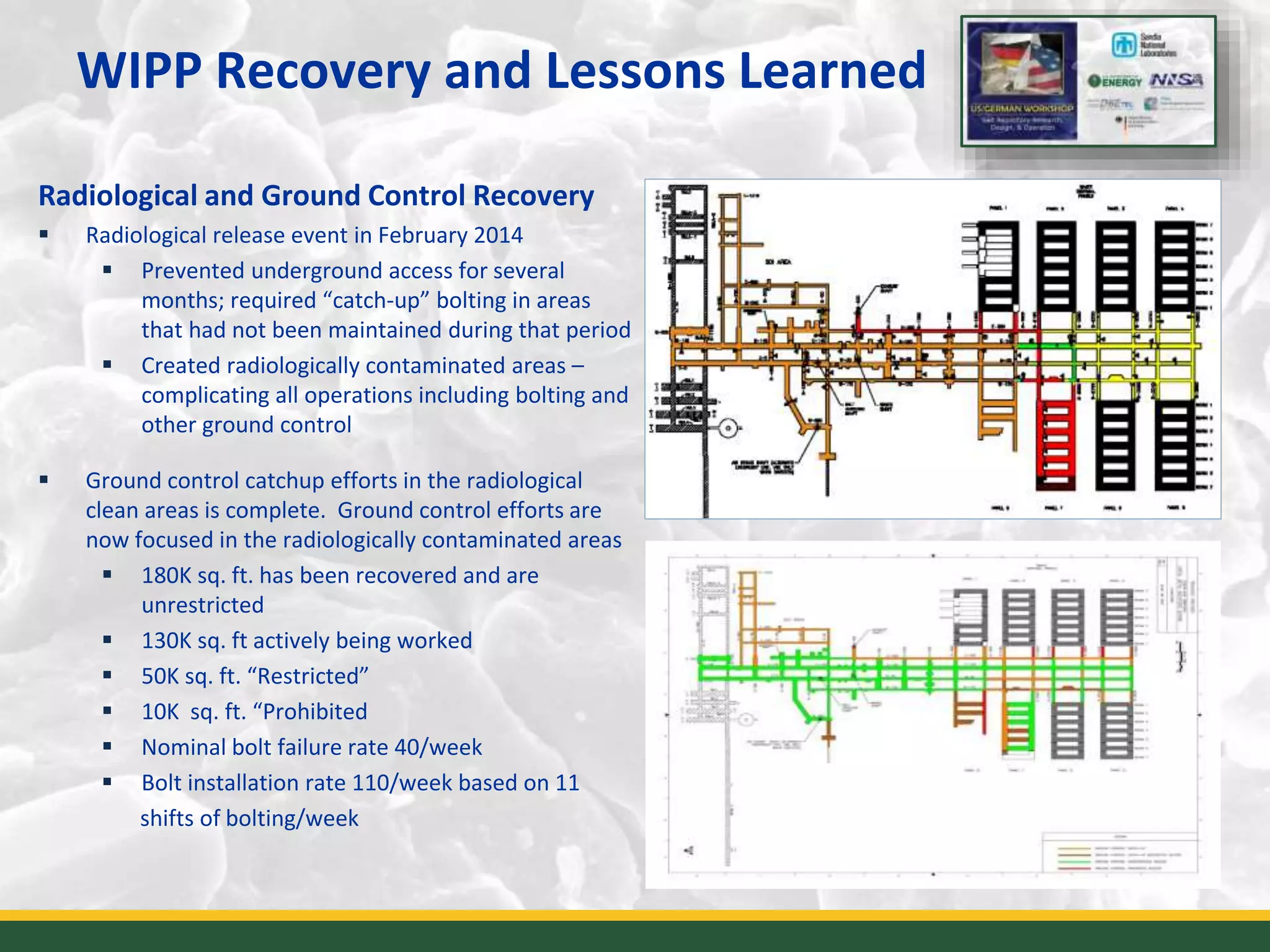

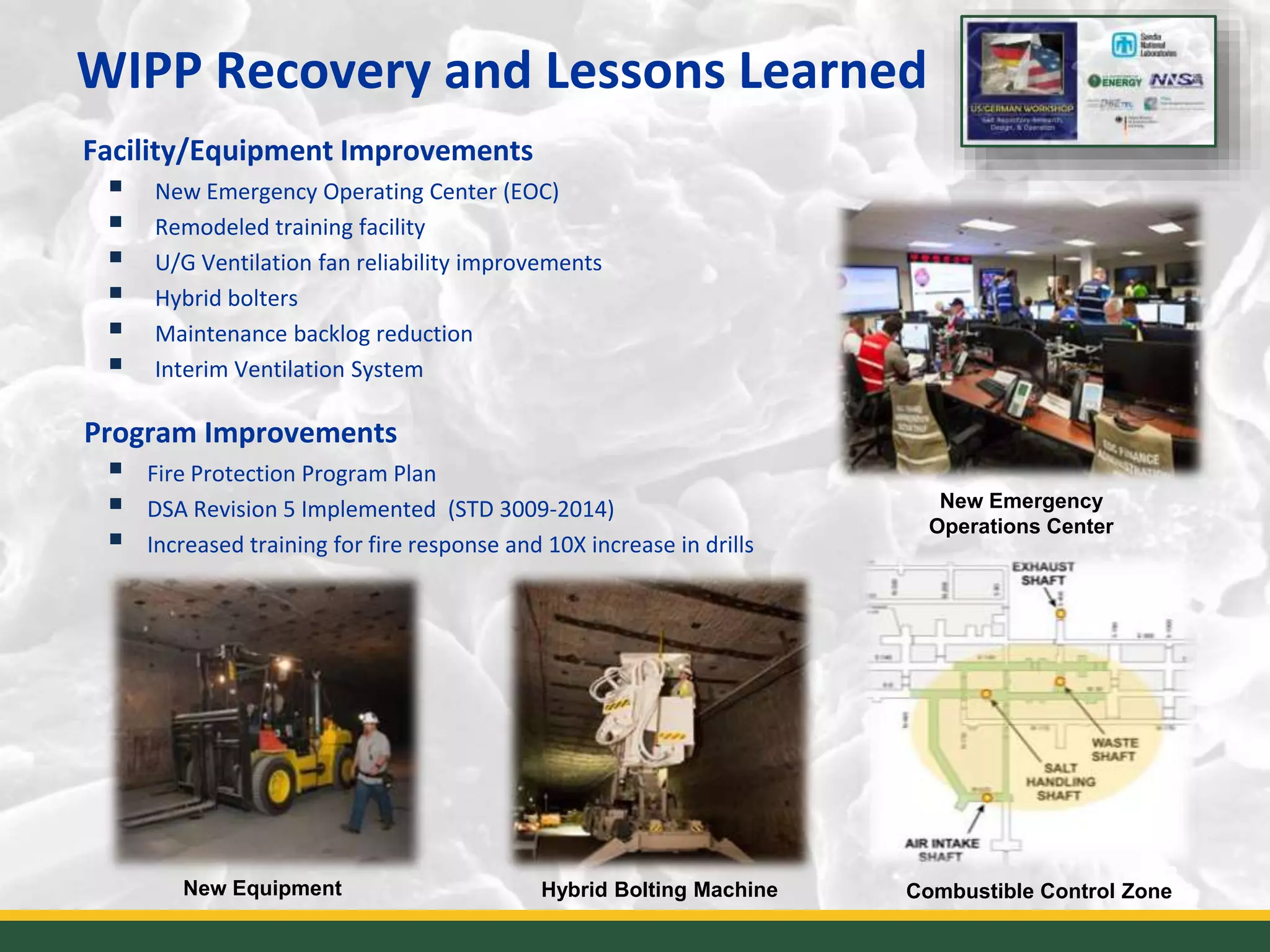

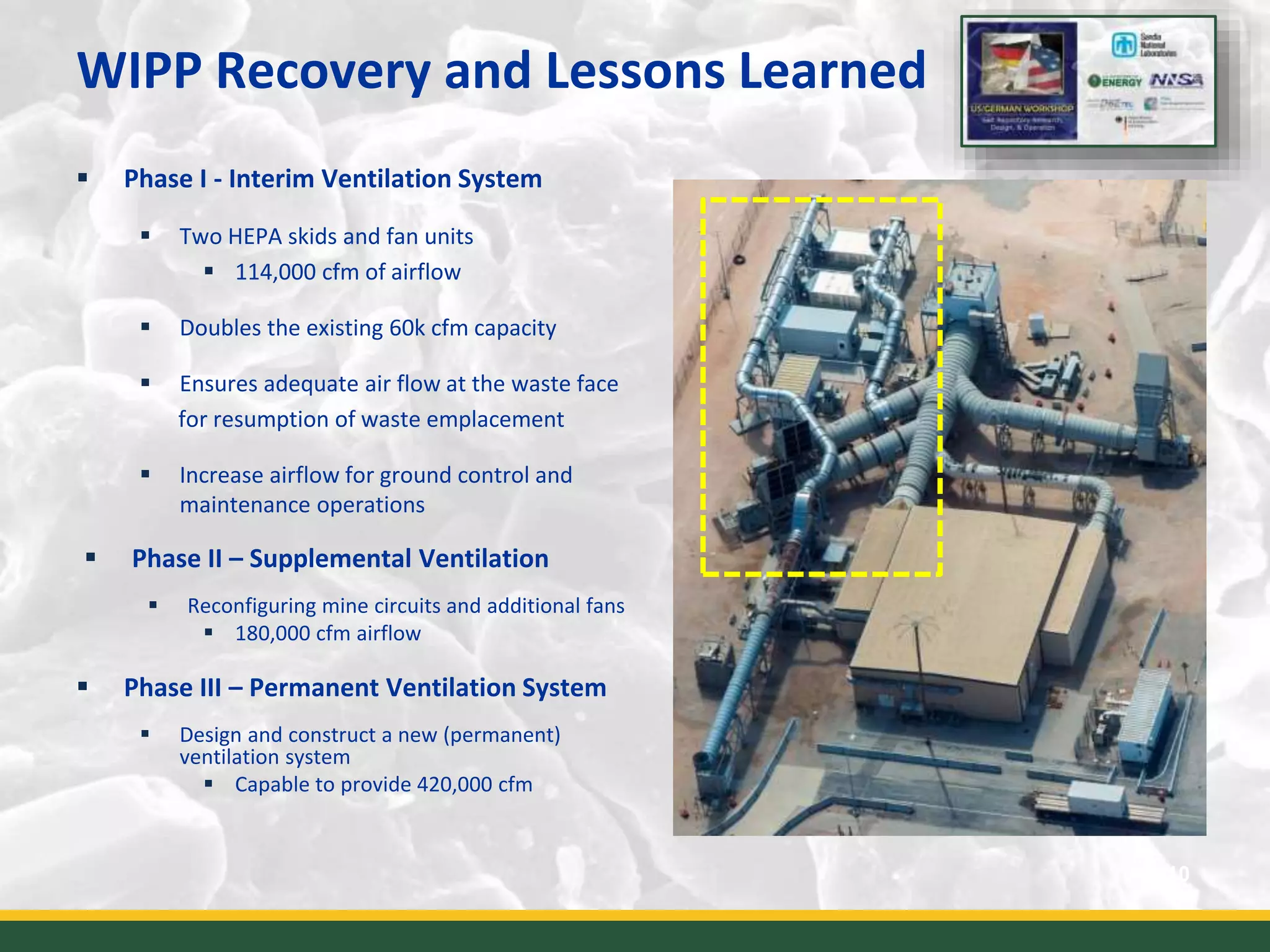

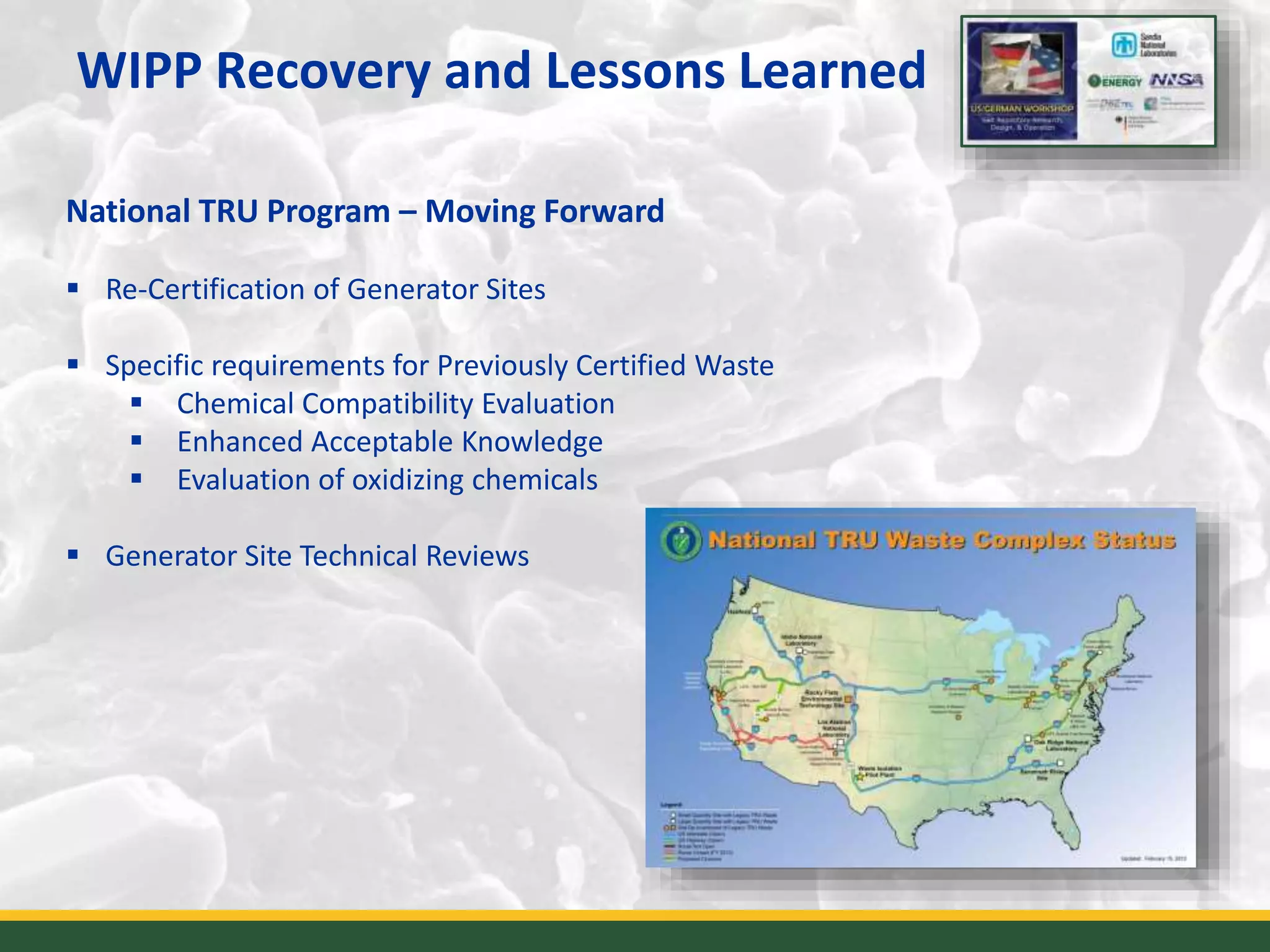

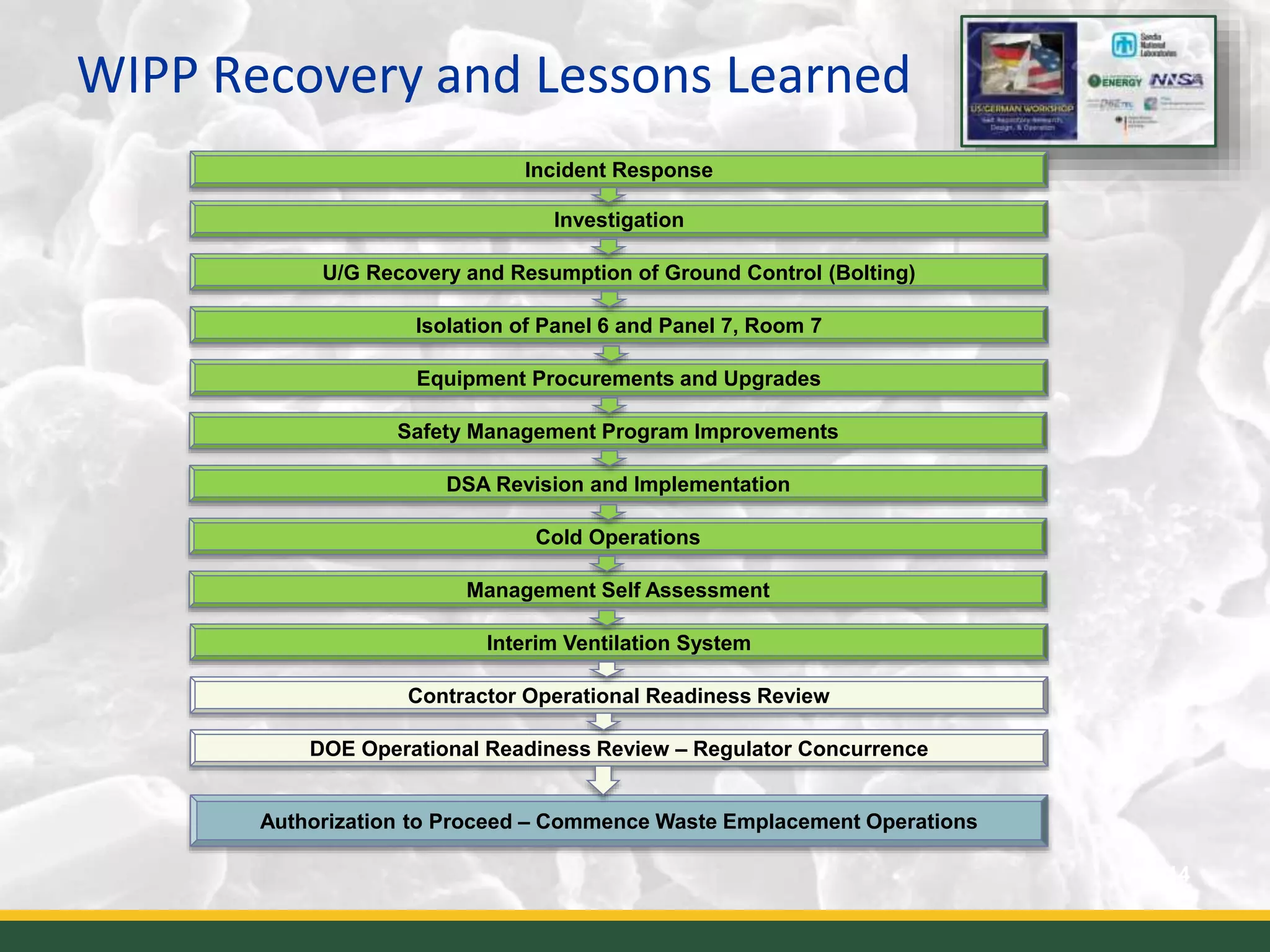

The document summarizes the recovery efforts at the Waste Isolation Pilot Plant (WIPP) in New Mexico following incidents in 2014 that paused operations. It describes the fire event on February 5th and radiological event on February 14th that contaminated some areas. It outlines lessons learned around maintenance, emergency response, and incompatible waste. It then summarizes the recovery project, including underground safety enhancements, ventilation system upgrades, and national TRU waste program changes to improve certification of generator sites before shipments resume.