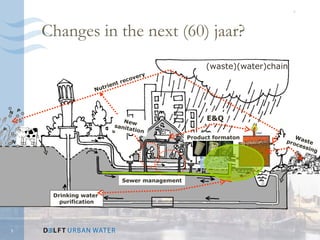

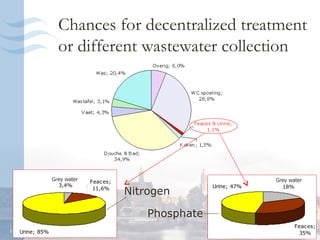

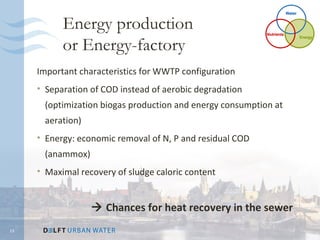

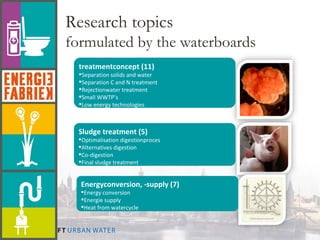

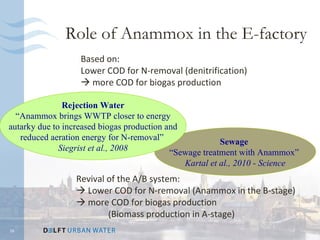

This document discusses trends and opportunities in wastewater treatment in the Netherlands over the next 60 years. It focuses on closing water, nutrient, and energy cycles by making wastewater treatment more sustainable. Key areas of focus include recovering nutrients and energy from wastewater, reducing energy usage, reusing water, and developing decentralized treatment methods. New treatment concepts like energy factories that integrate nutrient recovery and energy production are presented as ways to meet changing policy goals around water quality, energy reduction, and climate change.