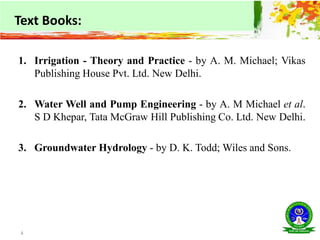

This document provides information about a course on pumps and wells, including the outline, aim, textbooks, and evaluation method. The course covers topics like pumps and pumping plants, deep well turbine and submersible pumps, water wells, tubewells, their design and construction, development and testing, and failure and rehabilitation. The aim is to teach the hydraulic principles applied to pumps and how to design, construct, and maintain pumps and irrigation projects. Students will be evaluated based on midterm exams, attendance, and a final exam worth 70 marks totaling 100 marks for the course.