Inventory Management System Guide

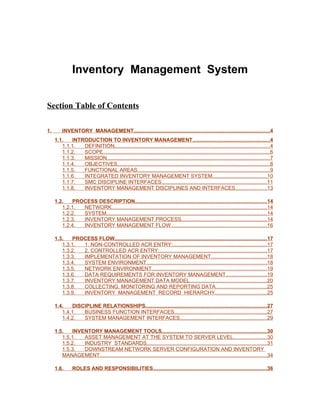

- 1. Inventory Management System Section Table of Contents 1. INVENTORY MANAGEMENT.............................................................................................4 1.1. INTRODUCTION TO INVENTORY MANAGEMENT.....................................................4 1.1.1. DEFINITION..........................................................................................................4 1.1.2. SCOPE..................................................................................................................6 1.1.3. MISSION...............................................................................................................7 1.1.4. OBJECTIVES........................................................................................................8 1.1.5. FUNCTIONAL AREAS..........................................................................................9 1.1.6. INTEGRATED INVENTORY MANAGEMENT SYSTEM.....................................10 1.1.7. SMC DISCIPLINE INTERFACES........................................................................11 1.1.8. INVENTORY MANAGEMENT DISCIPLINES AND INTERFACES.....................13 1.2. PROCESS DESCRIPTION..........................................................................................14 1.2.1. NETWORK..........................................................................................................14 1.2.2. SYSTEM.............................................................................................................14 1.2.3. INVENTORY MANAGEMENT PROCESS..........................................................14 1.2.4. INVENTORY MANAGEMENT FLOW.................................................................16 1.3. PROCESS FLOW........................................................................................................17 1.3.1. 1. NON-CONTROLLED ACR ENTRY:................................................................17 1.3.2. 2. CONTROLLED ACR ENTRY:.........................................................................17 1.3.3. IMPLEMENTATION OF INVENTORY MANAGEMENT......................................18 1.3.4. SYSTEM ENVIRONMENT..................................................................................18 1.3.5. NETWORK ENVIRONMENT..............................................................................19 1.3.6. DATA REQUIREMENTS FOR INVENTORY MANAGEMENT............................19 1.3.7. INVENTORY MANAGEMENT DATA MODEL....................................................20 1.3.8. COLLECTING, MONITORING AND REPORTING DATA...................................25 1.3.9. INVENTORY MANAGEMENT RECORD HIERARCHY...................................25 1.4. DISCIPLINE RELATIONSHIPS...................................................................................27 1.4.1. BUSINESS FUNCTION INTERFACES...............................................................27 1.4.2. SYSTEM MANAGEMENT INTERFACES...........................................................29 1.5. INVENTORY MANAGEMENT TOOLS........................................................................30 1.5.1. ASSET MANAGEMENT AT THE SYSTEM TO SERVER LEVEL.......................30 1.5.2. INDUSTRY STANDARDS..................................................................................31 1.5.3. DOWNSTREAM NETWORK SERVER CONFIGURATION AND INVENTORY MANAGEMENT..................................................................................................................34 1.6. ROLES AND RESPONSIBILITIES..............................................................................36

- 2. 1.6.1. INVENTORY MANAGER....................................................................................36 1.6.2. INVENTORY CLERKS........................................................................................36 1.7. PROCESS EVALUATION...........................................................................................37 1.7.1. PRESENT SYSTEM WEAKNESSES..................................................................37 1.7.2. RECOMMENDATIONS FOR IMPROVEMENT...................................................37

- 3. Section List of Figures FIGURE 1. ASSET MANAGEMENT PHASES AND OPERATIONS........................................................4 FIGURE 2: OVERVIEW OF INVENTORY MANAGEMENT FUNCTIONAL AREAS.........................19 FIGURE 3: OVERVIEW OF AN INTEGRATED INVENTORY MANAGEMENT SYSTEM................33 FIGURE 4: SMC DISCIPLINE INTERFACES ..........................................................................................45 FIGURE 5: INVENTORY MANAGEMENT SYSTEM - OVERVIEW OF PROCESS.....................118 FIGURE 6: INVENTORY SYSTEM FLOW DIAGRAM......................................................................131 FIGURE 7: INVENTORY MANAGEMENT DATA MODEL..............................................................221 FIGURE 8: INVENTORY MANAGEMENT RECORD HIERARCHY................................................325 FIGURE 9: ASSET MANAGEMENT AT THE SYSTEM TO SERVER LEVEL............................424 FIGURE 10: DOWNSTREAM NETWORK SERVER AND INVENTORY MANAGEMENT.........472 Inventory means goods and materials, or those goods and materials themselves, held available in stock by a business. This word is also used for a list of the contents of a household and for a list for testamentary purposes of the possessions of someone who has died. In accounting, inventory is considered an asset. In business management, inventory consists of a list of goods and materials held available in stock. Inventory refers to the stock of resources, that possess economic value, held by an organization at any point of time. These resource stocks can be manpower, machines, capital goods or materials at various stages. Inventory management is primarily about specifying the size and placement of stocked goods. Inventory management is required at different locations within a facility or within multiple locations of a supply network to protect the regular and planned course of production against the random disturbance of running out of materials or goods. The scope of inventory management also concerns the fine lines between replenishment lead time, carrying costs of inventory, asset management, inventory forecasting, inventory valuation, inventory visibility, future inventory price forecasting, physical inventory, available physical space for inventory, quality management, replenishment, returns and defective goods and demand forecasting. Balancing these competing requirements leads to optimal inventory levels, which is an on-going process as the business needs shift and react to the wider environment. Inventory management involves a retailer seeking to acquire and maintain a proper merchandise assortment while ordering, shipping, handling, and related costs are kept in check. Systems and processes that identify inventory requirements, set targets, provide replenishment techniques and report actual and projected inventory status.

- 4. Handles all functions related to the tracking and management of material. This would include the monitoring of material moved into and out of stockroom locations and the reconciling of the inventory balances. Also may include ABC analysis, lot tracking, cycle counting support etc. Management of the inventories, with the primary objective of determining/controlling stock levels within the physical distribution function to balance the need for product availability against the need for minimizing stock holding and handling costs 1.1.1. The reasons for keeping stock There are three basic reasons for keeping an inventory: 1. Time - The time lags present in the supply chain, from supplier to user at every stage, requires that you maintain certain amounts of inventory to use in this "lead time." 2. Uncertainty - Inventories are maintained as buffers to meet uncertainties in demand, supply and movements of goods. 3. Economies of scale - Ideal condition of "one unit at a time at a place where a user needs it, when he needs it" principle tends to incur lots of costs in terms of logistics. So bulk buying, movement and storing brings in economies of scale, thus inventory. All these stock reasons can apply to any owner or product stage. • Buffer stock is held in individual workstations against the possibility that the upstream workstation may be a little delayed in long setup or change over time. This stock is then used while that changeover is happening. This stock can be eliminated by tools like SMED. These classifications apply along the whole Supply chain, not just within a facility or plant. Where these stocks contain the same or similar items, it is often the work practice to hold all these stocks mixed together before or after the sub-process to which they relate. This 'reduces' costs. Because they are mixed up together there is no visual reminder to operators of the adjacent sub-processes or line management of the stock, which is due to a particular cause and should be a particular individual's responsibility with inevitable consequences. Some plants have centralized stock holding across sub-processes, which makes the situation even more acute. 1.1.2. [edit] Special terms used in dealing with inventory • Stock Keeping Unit (SKU) is a unique combination of all the components that are assembled into the purchasable item. Therefore, any change in the packaging or product is a new SKU. This level of detailed specification assists in managing inventory.

- 5. • Stockout means running out of the inventory of an SKU.[1] • "New old stock" (sometimes abbreviated NOS) is a term used in business to refer to merchandise being offered for sale that was manufactured long ago but that has never been used. Such merchandise may not be produced anymore, and the new old stock may represent the only market source of a particular item at the present time. 1.1.3. Typology 1. Buffer/safety stock 2. Cycle stock (Used in batch processes, it is the available inventory, excluding buffer stock) 3. De-coupling (Buffer stock that is held by both the supplier and the user) 4. Anticipation stock (Building up extra stock for periods of increased demand - e.g. ice cream for summer) 5. Pipeline stock (Goods still in transit or in the process of distribution - have left the factory but not arrived at the customer yet) 1.1.4. Inventory examples While accountants often discuss inventory in terms of goods for sale, organizations - manufacturers, service-providers and not-for-profits - also have inventories (fixtures, furniture, supplies, ...) that they do not intend to sell. Manufacturers', distributors', and wholesalers' inventory tends to cluster in warehouses. Retailers' inventory may exist in a warehouse or in a shop or store accessible to customers. Inventories not intended for sale to customers or to clients may be held in any premises an organization uses. Stock ties up cash and, if uncontrolled, it will be impossible to know the actual level of stocks and therefore impossible to control them. While the reasons for holding stock were covered earlier, most manufacturing organizations usually divide their "goods for sale" inventory into: • Raw materials - materials and components scheduled for use in making a product. • Work in process, WIP - materials and components that have begun their transformation to finished goods. • Finished goods - goods ready for sale to customers. • Goods for resale - returned goods that are salable. For example: 1.1.4.1.[edit] Manufacturing A canned food manufacturer's materials inventory includes the ingredients to form the foods to be canned, empty cans and their lids (or coils of steel or aluminum for constructing those components), labels, and anything else (solder, glue, ...) that will form part of a finished can. The firm's work in process includes those materials from the time of release to the work floor until they become complete and ready for sale to wholesale or retail customers. This may be vats of prepared food, filled cans not yet labeled or sub- assemblies of food components. It may also include finished cans that are not yet

- 6. packaged into cartons or pallets. Its finished good inventory consists of all the filled and labeled cans of food in its warehouse that it has manufactured and wishes to sell to food distributors (wholesalers), to grocery stores (retailers), and even perhaps to consumers through arrangements like factory stores and outlet centers. Examples of case studies are very revealing, and consistently show that the improvement of inventory management has two parts: the capability of the organisation to manage inventory, and the way in which it chooses to do so. For example, a company may wish to install a complex inventory system, but unless there is a good understanding of the role of inventory and its perameters, and an effective business process to support that, the system cannot bring the necessary benefits to the organisation in isolation. Typical Inventory Management techniques include Pareto Curve ABC Classification[2] and Economic Order Quantity Management. A more sophisticated method takes these two techniques further, combining certain aspects of each to create The K Curve Methodology[3]. A case study of k-curve[4] benefits to one company shows a successful implementation. Unnecessary inventory adds enormously to the working capital tied up in the business, as well as the complexity of the supply chain. Reduction and elimination of these inventory 'wait' states is a key concept in Lean[5]. Too big an inventory reduction too quickly can cause a business to be anorexic. There are well-proven processes and techniques to assist in inventory planning and strategy, both at the business overview and part number level. Many of the big MRP/and ERP systems do not offer the necessary inventory planning tools within their integrated planning applications. 1.2. Principle of inventory proportionality 1.2.1. Purpose Inventory proportionality is the goal of demand-driven inventory management. The primary optimal outcome is to have the same number of days' (or hours', etc.) worth of inventory on hand across all products so that the time of runout of all products would be simultaneous. In such a case, there is no "excess inventory," that is, inventory that would be left over of another product when the first product runs out. Excess inventory is sub- optimal because the money spent to obtain it could have been utilized better elsewhere, i.e. to the product that just ran out. The secondary goal of inventory proportionality is inventory minimization. By integrating accurate demand forecasting with inventory management, replenishment inventories can be scheduled to arrive just in time to replenish the product destined to run out first, while at the same time balancing out the inventory supply of all products to make their inventories more proportional, and thereby closer to achieving the primary goal. Accurate demand forecasting also allows the desired inventory proportions to be dynamic by determining expected sales out into the future; this allows for inventory to be in proportion to expected short-term sales or consumption rather than to past averages, a much more accurate and optimal outcome.

- 7. Integrating demand forecasting into inventory management in this way also allows for the prediction of the "can fit" point when inventory storage is limited on a per-product basis. 1.2.2. Applications The technique of inventory proportionality is most appropriate for inventories that remain unseen by the consumer. As opposed to "keep full" systems where a retail consumer would like to see full shelves of the product they are buying so as not to think they are buying something old, unwanted or stale; and differentiated from the "trigger point" systems where product is reordered when it hits a certain level; inventory proportionality is used effectively by just-in-time manufacturing processes and retail applications where the product is hidden from view. One early example of inventory proportionality used in a retail application in the United States is for motor fuel. Motor fuel (e.g. gasoline) is generally stored in underground storage tanks. The motorists do not know whether they are buying gasoline off the top or bottom of the tank, nor need they care. Additionally, these storage tanks have a maximum capacity and cannot be overfilled. Finally, the product is expensive. Inventory proportionality is used to balance the inventories of the different grades of motor fuel, each stored in dedicated tanks, in proportion to the sales of each grade. Excess inventory is not seen or valued by the consumer, so it is simply cash sunk (literally) into the ground. Inventory proportionality minimizes the amount of excess inventory carried in underground storage tanks. This application for motor fuel was first developed and implemented by Petrolsoft Corporation in 1990 for Chevron Products Company. Most major oil companies use such systems today.[6] 1.2.3. Roots The use of inventory proportionality in the United States is thought to have been inspired by Japanese just-in-time (business) parts inventory management made famous by Toyota Motors in the 1980s 1.3. High-level inventory management It seems that around 1880[7] there was a change in manufacturing practice from companies with relatively homogeneous lines of products to vertically integrated companies with unprecedented diversity in processes and products. Those companies (especially in metalworking) attempted to achieve success through economies of scope - the gains of jointly producing two or more products in one facility. The managers now needed information on the effect of product-mix decisions on overall profits and therefore needed accurate product-cost information. A variety of attempts to achieve this were unsuccessful due to the huge overhead of the information processing of the time. However, the burgeoning need for financial reporting after 1900 created unavoidable pressure for financial accounting of stock and the management need to cost manage products became overshadowed. In particular, it was the need for audited accounts that sealed the fate of managerial cost accounting. The dominance of financial reporting

- 8. accounting over management accounting remains to this day with few exceptions, and the financial reporting definitions of 'cost' have distorted effective management 'cost' accounting since that time. This is particularly true of inventory. Hence, high-level financial inventory has these two basic formulas, which relate to the accounting period: 1. Cost of Beginning Inventory at the start of the period + inventory purchases within the period + cost of production within the period = cost of goods available 2. Cost of goods available − cost of ending inventory at the end of the period = cost of goods sold The benefit of these formulae is that the first absorbs all overheads of production and raw material costs into a value of inventory for reporting. The second formula then creates the new start point for the next period and gives a figure to be subtracted from the sales price to determine some form of sales-margin figure. Manufacturing management is more interested in inventory turnover ratio or average days to sell inventory since it tells them something about relative inventory levels. Inventory turnover ratio (also known as inventory turns) = cost of goods sold / Average Inventory = Cost of Goods Sold / ((Beginning Inventory + Ending Inventory) / 2) and its inverse Average Days to Sell Inventory = Number of Days a Year / Inventory Turnover Ratio = 365 days a year / Inventory Turnover Ratio This ratio estimates how many times the inventory turns over a year. This number tells how much cash/goods are tied up waiting for the process and is a critical measure of process reliability and effectiveness. So a factory with two inventory turns has six months stock on hand, which is generally not a good figure (depending upon the industry), whereas a factory that moves from six turns to twelve turns has probably improved effectiveness by 100%. This improvement will have some negative results in the financial reporting, since the 'value' now stored in the factory as inventory is reduced. Whilst these accounting measures of inventory are very useful because of their simplicity, they are also fraught with the danger of their own assumptions. There are, in fact, so many things that can vary hidden under this appearance of simplicity that a variety of 'adjusting' assumptions may be used. These include: • Specific Identification • Weighted Average Cost • Moving-Average Cost • FIFO and LIFO.

- 9. Inventory Turn is a financial accounting tool for evaluating inventory and it is not necessarily a management tool. Inventory management should be forward looking. The methodology applied is based on historical cost of goods sold. The ratio may not be able to reflect the usability of future production demand, as well as customer demand. Business models, including Just in Time (JIT) Inventory, Vendor Managed Inventory (VMI) and Customer Managed Inventory (CMI), attempt to minimize on-hand inventory and increase inventory turns. VMI and CMI have gained considerable attention due to the success of third-party vendors who offer added expertise and knowledge that organizations may not possess. 1.3.1. Role of inventory accounting By helping the organization to make better decisions, the accountants can help the public sector to change in a very positive way that delivers increased value for the taxpayer’s investment. It can also help to incentivise progress and to ensure that reforms are sustainable and effective in the long term, by ensuring that success is appropriately recognized in both the formal and informal reward systems of the organization. To say that they have a key role to play is an understatement. Finance is connected to most, if not all, of the key business processes within the organization. It should be steering the stewardship and accountability systems that ensure that the organization is conducting its business in an appropriate, ethical manner. It is critical that these foundations are firmly laid. So often they are the litmus test by which public confidence in the institution is either won or lost. Finance should also be providing the information, analysis and advice to enable the organizations’ service managers to operate effectively. This goes beyond the traditional preoccupation with budgets – how much have we spent so far, how much do we have left to spend? It is about helping the organization to better understand its own performance. That means making the connections and understanding the relationships between given inputs – the resources brought to bear – and the outputs and outcomes that they achieve. It is also about understanding and actively managing risks within the organization and its activities. 1.3.2. FIFO vs. LIFO accounting Main article: FIFO and LIFO accounting When a merchant buys goods from inventory, the value of the inventory account is reduced by the cost of goods sold (COGS). This is simple where the CoG has not varied across those held in stock; but where it has, then an agreed method must be derived to evaluate it. For commodity items that one cannot track individually, accountants must choose a method that fits the nature of the sale. Two popular methods that normally exist are: FIFO and LIFO accounting (first in - first out, last in - first out). FIFO regards the first unit that arrived in inventory as the first one sold. LIFO considers the last unit arriving in inventory as the first one sold. Which method an accountant selects can have a

- 10. significant effect on net income and book value and, in turn, on taxation. Using LIFO accounting for inventory, a company generally reports lower net income and lower book value, due to the effects of inflation. This generally results in lower taxation. Due to LIFO's potential to skew inventory value, UK GAAP and IAS have effectively banned LIFO inventory accounting. 1.3.3. Standard cost accounting Standard cost accounting uses ratios called efficiencies that compare the labour and materials actually used to produce a good with those that the same goods would have required under "standard" conditions. As long as similar actual and standard conditions obtain, few problems arise. Unfortunately, standard cost accounting methods developed about 100 years ago, when labor comprised the most important cost in manufactured goods. Standard methods continue to emphasize labor efficiency even though that resource now constitutes a (very) small part of cost in most cases. Standard cost accounting can hurt managers, workers, and firms in several ways. For example, a policy decision to increase inventory can harm a manufacturing manager's performance evaluation. Increasing inventory requires increased production, which means that processes must operate at higher rates. When (not if) something goes wrong, the process takes longer and uses more than the standard labor time. The manager appears responsible for the excess, even though s/he has no control over the production requirement or the problem. In adverse economic times, firms use the same efficiencies to downsize, rightsize, or otherwise reduce their labor force. Workers laid off under those circumstances have even less control over excess inventory and cost efficiencies than their managers. Many financial and cost accountants have agreed for many years on the desirability of replacing standard cost accounting. They have not, however, found a successor. 1.3.4. Theory of constraints cost accounting Eliyahu M. Goldratt developed the Theory of Constraints in part to address the cost- accounting problems in what he calls the "cost world." He offers a substitute, called throughput accounting, that uses throughput (money for goods sold to customers) in place of output (goods produced that may sell or may boost inventory) and considers labor as a fixed rather than as a variable cost. He defines inventory simply as everything the organization owns that it plans to sell, including buildings, machinery, and many other things in addition to the categories listed here. Throughput accounting recognizes only one class of variable costs: the truly variable costs, like materials and components, which vary directly with the quantity produced. Finished goods inventories remain balance-sheet assets, but labor-efficiency ratios no longer evaluate managers and workers. Instead of an incentive to reduce labor cost, throughput accounting focuses attention on the relationships between throughput

- 11. (revenue or income) on one hand and controllable operating expenses and changes in inventory on the other. Those relationships direct attention to the constraints or bottlenecks that prevent the system from producing more throughput, rather than to people - who have little or no control over their situations. 1.4. National accounts Inventories also play an important role in national accounts and the analysis of the business cycle. Some short-term macroeconomic fluctuations are attributed to the inventory cycle. 1.5. Distressed inventory Also known as distressed or expired stock, distressed inventory is inventory whose potential to be sold at a normal cost has passed or will soon pass. In certain industries it could also mean that the stock is or will soon be impossible to sell. Examples of distressed inventory include products that have reached their expiry date, or have reached a date in advance of expiry at which the planned market will no longer purchase them (e.g. 3 months left to expiry), clothing that is defective or out of fashion, and old newspapers or magazines. It also includes computer or consumer-electronic equipment that is obsolete or discontinued and whose manufacturer is unable to support it. One current example of distressed inventory is the VHS format.[8] In 2001, Cisco wrote off inventory worth US $2.25 billion due to duplicate orders [9]. This is one of the biggest inventory write-offs in business history. 1.6. Inventory credit Inventory credit refers to the use of stock, or inventory, as collateral to raise finance. Where banks may be reluctant to accept traditional collateral, for example in developing countries where land title may be lacking, inventory credit is a potentially important way of overcoming financing constraints. This is not a new concept; archaeological evidence suggests that it was practiced in Ancient Rome. Obtaining finance against stocks of a wide range of products held in a bonded warehouse is common in much of the world. It is, for example, used with Parmesan cheese in Italy.[10] Inventory credit on the basis of stored agricultural produce is widely used in Latin American countries and in some Asian countries.[11] A precondition for such credit is that banks must be confident that the stored product will be available if they need to call on the collateral; this implies the existence of a reliable network of certified warehouses. Banks also face problems in valuing the inventory. The possibility of sudden falls in commodity prices means that they are usually reluctant to lend more than about 60% of the value of the inventory at the time of the loan Inventory Management System

- 12. The system integrates the idea to manage the inventory automatically, meanwhile it can generate sales report, inventory report, etc. To users, the system can provide instant information about all inventory items. Therefore users who manage stock level can immediately solve any shortage problems, since the system provides easy-to-use interface for users to see inventory levels. By recording daily sales, the system updates inventory constantly with the help of database management system running as the back end. System Architecture: For more information, kindly send us your enquires through our Consulting Requisition form and we will reply accordingly. Thank you. Inventory Management System/ Supply Chain Management System World biggest Pan Masala Manufacturer wants a solution to control the following area, • Control heavy routine business transaction • Supply chain maintenance • Fund maintenance • Complex MIS • Large Business Data An integrated software solution provided by us to them. Replacement of old software with new one and conversion of data to a world standard RDBMS (Oracle). The solution was a GUI interface with end user in Visual Basic as front and ORACLE as back end DBMS. Crystal Reports was used to display / view complex MIS as well as daily operational reports, ready to be exported in any file format. Adoption of new technology helps management to transmit information over internet with no time. Cash flow / Fund flow maintenance has become easier now. This gives a tool to management for making complex business decisions in less time span and ultimate result was cut in production and maintenance cost. 1. 1. Inventory Management

- 13. 1.1. 1.1. Introduction to Inventory Management 1.1.1. 1.1.1. Definition Inventory Management is an enterprise-wide discipline concerned with the identification and tracking of Information Services (IS) hardware and software assets. Its three main areas of concern are: Acquisition. Redeployment. Termination. Can be sorted by: Equipment Type, Disposition, and Location Pick-Up List Equip. Type: Disp: Location: PC A Bldg 3, Rm 203 Start PC R Bldg 1, Rm 405 PC T Bldg 2, Rm 501 Disposition = ‘A’ Acquire Purchase Install Add to Master Equipment Order Equipment Master Inventory Inventory Equipment is being Actively used Disposition = ‘R’ N, Exceptions List Generated Re-deploy Compare to Y Work Pick-Up Warehouse Master Inventory Equipment Order Inventory Inventory Equipment is moved to new location Perform Service Services Order Disposition = ‘T’ Terminate Work Service Ready-to-Sell Purchase Release Finance Equipment Order Order Order Form Form Inventory Equipment is Sold or Disposed of Marketing & Sales End Archive Figure 1. Asset Management phases and operations Acquisition procedures are established to assist personnel in procurement of software and hardware products. Its main purpose is to ensure that proper justifications are performed and that financial guidelines are followed. Acquisitions require “Purchase Orders” to track and authorize the purchase, while the actual installation of equipment is performed by the Infrastructure or Facilities Management Department. Once added to

- 14. the environment, a Master Inventory record is created to describe the newly added equipment and its components (i.e., Pentium IV PC with 512 MB or RAM, a 40 GB Hard Drive, CD Drive, Floppy Drive, Sound and Video Cards, a 56 KB Modem and a 10/100 Ethernet Connection, etc.). Inventory records can be used to calculate the resale price of existing equipment, when planning for an upgrade / replacement or reduction in size. The Inventory Report can be used to inform buyers of your stock and obtain bids on the purchase of your surplus equipment. Redeployment procedures are responsible for ensuring that assets are tracked when moved from one location to another and that budgetary considerations are adjusted as needed. Should a product be moved in from its original owner, then the Inventory System is updated to reflect the new location and owner. In this case, the old product is deleted from the original owner's budget and added to the new owner's budget. If equipment is being deployed from one person, or location, to another, then a data wipe operation must be performed to insure that sensitive business, personal and/or medical information has been deleted. If data wiping procedures are not performed in accordance to Department of Defense standards, then the company is open to legal and civil penalties as defined in a number of laws (i.e., Sarbanes-Oxley, Gramm-Leach-Bliley, HIPAA) Redeployment requests can generate transportation activity (pick-up and delivery of equipment), facilities management activity (disconnecting device, data wipe, reconnecting device, etc.), inventory management update, and service activities associated with the device(s) being moved. Termination is responsible for deleting the asset from the inventory when it is discontinued, or replaced. The owner's budget will be updated to reflect the asset termination and the asset will no longer be listed when location reports are generated. Whenever equipment is being terminated (even if for donation to charities or employees) a data wipe operation must be performed to eliminate any sensitive information from the hard drive. Additionally, a certified vendor must be utilized to insure that the computers components are disposed of in an environemtally friendly manner. This scrapping process must be certified, so that legal and civil penalties are no longer the responsibility of the terminating firm but rather the scrapping organization. The Inventory System is maintained within a data base that ties an asset to its owner and defines the location where the asset resides. The relative importance of the asset is added to the inventory record in a Criticality field (i.e., Criticality = 1-5, where 1 is "Most Critical") and the current status of the equipment is indicated via a status field (A=Active, R=Redeploying, D=Donated, T=Terminated, etc.). Based on this information the contingency planning specialist can plan asset recoveries needed to support critical business operations and the facilities management group can schedule work events associated with equipment status changes (i.e., from A to R, or A to T, or A to D, etc.). Like all data bases, the Inventory System will only be effective if its information is kept current. To ensure the accuracy of the Inventory System, while not adding too great a burden to company personnel, every effort must be taken to implement processes that maintain inventory data with a minimum work effort from personnel. To that end, we

- 15. suggest automated form tied to equipment status and criticality changes, so that facilities management and business continuity planning can adjust their functions accordingly. Inventory Management provides: Up-to-date information about data processing resources through the creation and archiving of records in a centralized repository. Financial records specific to a single component, or groups of components. Component Status Indicators to identify a component as Active (A), Redeployed (R ), Donated (D), or Terminated (T). Component Criticality definition (1-5, with 1 being most critical). Service records for all components in the inventory. Data used to support configuration diagrams of the hardware and software components contained within specific locations, or the entire data processing environment. Reports can be generated from the Inventory and Asset Management Systems that would project the amount of revenue that can be generated through the sale of surplus equipment, or to define the number of components that have a criticality rating of ‘1’ so that you can project the costs associated with maintaining duplicates of critical equipment at reovery sites. Combining the two reports would allow you to reroute equipment being scheduled for termination to the Recovery Facility and eliminate the additional costs associated with purchasing duplicate equipment in support of recovery needs.

- 16. 1.1.2. 1.1.2. Scope The Inventory Management discipline encompasses all system and data network elements from the mainframe to the server level throughout the enterprise. All mainframe and data network based hardware and software assets must be identified and entered into the Inventory System. Any changes to these environments must be reflected in the Inventory System. Financial and technical product information must be available through the Inventory System, as needed to support the functional responsibilities of personnel within the finance and contracts management departments. Asset criticality must be included with asset descriptive and financial information, so that the Recovery Management department is supplied with the information it requires. Recovery actions must be implemented to safeguard critical assets. Asset status must be included in the Inventory Management system, so that the component(s) can be serviced in adherence to legal, environmental, business, and industry requirements. This process should be used to drive the facilities management department via form routing when components change status from active to redeploy, donate, terminate, of scrap. An audit trail of activities associated with equipment status changes and associated actions must be maintained to certify actions and eliminate legal and civil exposures. The Standards and Procedures Manual section relating to Inventory Management must be created and published. This section must describe the process by which assets are identified, entered into the Inventory Management System, tracked, and finally deleted. All information needed by personnel to perform Inventory Management functions must be clearly described within this S&P Manual section.

- 17. 1.1.3. 1.1.3. Mission The mission of an Inventory System is to provide a Central Asset Repository of information used to define assets and relate the asset to its; owner, location, and relative importance. This information will provide personnel with data needed to support their job functions, for example: Facilities Management will be able to plan Heating, Ventilation and Air Conditioning (HVAC) requirements, as well as power and floor space needed to support equipment listed in Asset Repository for a specific location. To also perform the functions needed to adhere to legal, environmental, business, and regulatory requirements associated with equipment redeployment and termination. Financial Services will be able to budget for asset procurement, depreciate assets over time, and complete tax documents. A report of equipment and their resale value can be used to aid in planning equipment upgrades and to reduce the “Total Cost of Ownership” associated with equipment. Contracts Management will be able to negotiate vendor discounts and enterprise agreements. Additional vendor agreements may be required to support transportation and warehousing, equipment service and reconfiguration requirements, data wipe services and products, buyers, and scrap dealers. Contingency Planning personnel will be able to develop recovery plans for mainframe and office assets contained within the Inventory System, based on the assets relative importance (as stated within the Criticality field). Surplus equipment may be utilized to support recovery operations, if needed. Technical personnel will be able to resolve problems more quickly with the information contained within the Inventory System, because they will have a listing of the assets contained within a location. The Inventory System should be integrated within the everyday functions performed by personnel associated with entering and maintaining asset information. The system will reduce the effort devoted to asset management, while supplying many personnel with the information they need to perform their functional responsibilities.

- 18. 1.1.4. 1.1.4. Objectives The objective of Inventory Management is to manage the physical and logical properties of I/S resources and their relationship, while ensuring that service level commitments are achieved. This process will: Ensure efficient and timely identification of vital corporate assets. Assist in managing the enterprise-wide inventory. Provide a common repository for asset protection. Plan and control the proliferation of assets across the enterprise. The objectives of Inventory Management are: To identify and track all data processing assets in an Inventory System Repository. To define the process by which assets are identified and maintained in the Inventory System. To provide Inventory System access to all necessary personnel (data entry, update and deletion). To provide a full range of reports that will satisfy informational requirements. To document the Inventory Management System within the Standards and Procedures Manual. To provide training to personnel responsible for supporting the Inventory Management System.

- 19. 1.1.5. 1.1.5. Functional Areas. The functional areas that interface with an Inventory Management System are: Inventory Management Departments “ Inventory Management is divided into many separate areas of responsibility.” Finance Inventory Management Contracts Mainframe Mid-Range PC / LAN Communications Fixed Assets Voice Data Network Hardware Software Facilities Common areas of concern faced by each department Vendor Financial Figure 2: Overview of Inventory Management functional areas. All of the functional areas listed above can utilize the information contained within the Inventory Management System's Central Asset Repository of information. Additionally, the Recovery Management area could utilize inventory information to identify an assets criticality (especially when the asset's location and owner are identified within the Inventory Management System). Through the use of reports generated from the Inventory Management System's Repository, it would be possible to obtain a listing of all "Most Critical" resources, by location and group. This report would then serve as the basis of a Business Recovery Plan.

- 20. 1.1.6. 1.1.6. Integrated Inventory Management System To successfully implement an Inventory Management System, it is necessary to integrate it within the everyday functions performed by company personnel. That is, when a user wants to order equipment or software, they would call up the Inventory Management System screen associated with Acquisition. The same types of processes should be available for Redeployment and Termination of assets. Should a user request the acquisition of a specific type of asset, then it could be possible for the inventory system to determine if the asset is already in surplus, or if it should be purchased under an existing Volume Purchase Agreement with a vendor. Inventory Management Process Flow User’s make requests for resources (either hardware, software, or fixed assets such as furniture). To ensure USER USER accuracy of Inventory, all requests must be via system connected terminal. Inventory Management Inventory Control Financial Management Management Financial profile of inventory is Inventory of assets is controlled by the provided to Financial Management, Inventory Control Manager. who recommend purchasing techniques Enterprise design agreements are Reports that will result in discounts (i..e., validated by this person, who also Repository Volume Purchase Agreements, or ensures that all asset guidelines are specific vendors). adhered to. Hardware, Software, Fixed Assets, All reports deemed by Location necessary to support and Criticality system and informational requests. Figure 3: Overview of an integrated Inventory Management System. The utilization of Inventory Management Systems to control the purchase and installation of assets can aid in the control of the business environment, while assisting in the assignment of personnel to perform asset related work functions. This methodology will result in a work-flow and asset management system.

- 21. 1.1.7. 1.1.7. SMC Discipline Interfaces The Systems Management and Controls disciplines that will interface with the Inventory Management System are illustrated within the diagram listed below. SMC Organization Systems Management and Controls (SMC) Batch Service Level Recovery Change Management Management Management Management Inventory EDP Security Problem On-Line Management Management Management Management Configuration Management Vital Records Management Capacity Management Performance Management Figure 4: SMC Discipline Interfaces . The disciplines interfacing directly with Inventory Management and their functional responsibilities are: Capacity Management (i.e., PC memory and speed, DASD size, etc.). Performance Management (speed and usage information). Change Management (version and release information, benchmark, testing, etc.). Recovery Management (recovery planning for critical assets and sizing requirements for recovery facilities).

- 22. Service Level Management (Service Level Definitions - SLD's and Service Level Reporting - SLR of user processing and service requirements). Problem Management (troubleshooting, pathway, version and release information, etc.). Configuration Management (hardware, software, location, HVAC requirements, power, water, floor space, etc.).

- 23. 1.1.8. 1.1.8. Inventory Management disciplines and interfaces The Inventory Management function is responsible for tracking all assets, from Mainframe based to Data Network based, that are connected to the data center or data network. In each case, the Inventory Management Systems must be able to: Identify the asset and its serial number; Associate the asset with its owner and location; Relate the asset to its vendor; and Track the maintenance level of the asset. The ideal Inventory Management System should also: Provide financial information related to an asset; Define the criticality of the asset; and Supply history information for the asset. The Inventory Management System interfaces with the following departments: Finance; Contracts; Systems Software; Production Services; and Facilities Management.

- 24. 1.2. 1.2. Process Description The process of Inventory Management receives input from Systems Management Controls (SMC) disciplines and other functions within the I/S organization as well as other areas throughout the enterprise. The vehicle used to control the Inventory Management discipline is Change Management. Without adequate Change Management the integrity of an Inventory Management process cannot be ensured. These SMC disciplines and functions encompass both system and data network elements and feed the Configuration Management discipline. Inventory Management inputs can come from either the Network or System area and can include a variety of input methods: 1.2.1. 1.2.1. Network The Network area must account for new acquisitions installed into the configuration. Because the complexity of today’s networks makes tracking new acquisitions difficult, it is advisable that tracking be accomplished through the use of discovery type applications which monitor and interrogate asset changes automatically. This type of tracking would capture vital product data (VPD), or perform product identification which is generally imbedded on PC-type products by the manufacturer. 1.2.2. 1.2.2. System Within the system area changes to the physical environment are systematically reported through the integrated change process. This discipline incorporates all hardware and software reconfigurations or updates. All inputs to the centralized data base will be subject to the change process. The following page contains an overview of the Inventory Management process. 1.2.3. 1.2.3. Inventory Management Process

- 25. PROCESS INPUTS: Service Level Management, Capacity and Performance Management, Change Management, Problem Management, Batch Management, On-Line Management, Recovery Management New Asset Asset Network System Acquisition Re-Deployment Termination Alert Re-Configuration Data Center Record, System Management System Record, Assurance Process To Hardware Record, Inventory Repository Configuration Software Record, Management Service Record, Data Base Financial Record. R/O R/W Reports Hard Copy, or On-Line Viewing Add / Delete / Edit via on-line Display Figure 5: Inventory Management System - Overview of Process The above provides an Overview Diagram of the Inventory Management process, while the following illustration provides a Flow Diagram of the Inventory Process.

- 26. 1.2.4. 1.2.4. Inventory Management Flow SMC No Create Disciplines Data Center No Generate Data Financials Record Physical Center ? ? Inventory Non-Controlled Record Reports Entry Yes Yes Controlled Entry System No Create Record System Financial No Create Unformatted Generate ? Record Record Financial Asset Change Yes ? Record Request Record Yes Create Validate Hardware Generate Validate Data Software Financial Data Elements Record Reports Elements Create Yes No Yes Features Features Close Change Accepted No ? Record Record ? Formatted? Authorized? No Yes Does Config. Yes Update Change Configuration ? Data Base Generate Physical No Configuration Reports Figure 6: Inventory System Flow Diagram

- 27. 1.3. 1.3. Process Flow. The process is entered as a Controlled or Non-Controlled Asset Change Request (ACR) as follows: 1.3.1. 1.3.1. 1. Non-Controlled ACR Entry: ACR received by any method other than the Change Control process. - Confirm all necessary information is available about the asset. - Request is reviewed locally for acceptance. - Problems documented and returned for resolution. - ACR accepted and authorized. - Request forwarded to Change Control process for input as a Controlled ACR. 1.3.2. 1.3.2. 2. Controlled ACR Entry: Validate all data elements are present in the Change Record. Review by all I/S organizations accountable for asset control. Problems documented and returned for resolution. ACR accepted and authorized. Update Inventory Repository data base. Create data center record associated with the asset. Create system record associated with the asset. Create component record associated with the asset. Create feature records associated with the asset. Generate physical configuration reports and distribute. Create financial records if appropriate. Generate financial reports if appropriate. Generate physical inventory reports and distribute. Close the change record.

- 28. 1.3.3. 1.3.3. Implementation of Inventory Management Efficient processing and operations management start with an integrated approach that links all facets of system management together. Inventory Management is just one of the disciplines. Each augments the other, and provides the ability to effectively manage a large systems environment. Accurate inventory data is vital. A lack of such data affects the other Systems Management disciplines ability to function. The automated element of inventory management monitors the enterprise-wide data network processing environment for change, while the system environment relies on the change process (which may or may not be fully automated) for accurate input. The products and tools that comprise the Inventory Management System use data network definition information, Vital Product Data, local configuration definitions and in some cases, discovery applications to arrive at inventory information. This process must embrace the following areas to be effective: 1.3.4. 1.3.4. System Environment Today the system programmer can define hardware configurations for multiple MVS/ESA operating systems through Hardware Configuration Definition (HCD). HCD reduces complexity and shortens the time required to successfully define an I/O configuration by providing a panel-driven interface, panel defaults, and data entry validity checking. Dynamic reconfiguration management allows the support organization to implement system configuration changes without interrupting system service. System availability is increased by eliminating the need for an IPL to change the hardware configuration, or to change the software definition for devices, control units, and channel paths. This ability to dynamically reconfigure works in conjunction with HCD and allows the new system configuration to be implemented without interruption. Enterprise Systems Connection (ESCON) Manager enhances user control and manageability in an ESCON architecture environment when changing ESCON Director (ESCD) configurations. The changes are entered at a host processor rather than at the local ESCD consoles in the mainframe environment. HCD and ECSON are highly dynamic tools that can effect configuration changes easily and swiftly. However, there are no automation techniques currently in use which update the inventory data base. Updates to the inventory data base require

- 29. manual intervention, therefore, it is important that these interfaces to HCD and ESCON be constantly monitored and proper change control exercised to maintain asset integrity. 1.3.5. 1.3.5. Network Environment The complexity of the network environment requires an integrated set of facilities to store and display network configuration data for all network resources. This includes OSI, TCP/IP, SNA, Ethernet, and any other network resources. These facilities are tailored for network operational use and contain information that is pertinent to hardware and software inventories (e.g., Vital Product Information). When dealing with large networks the immediate problems associated with the collection of asset information is enormous and therefore, subject to significant errors. If the configurations are too complex, they become impossible to manage or understand. The typical network is composed of many nodes extending to many different topologies. The technique commonly used to manage networks is to break up the larger networks into smaller, manageable units. Once the management of these clusters is underway, you can proceed to manage several clusters from a higher node in the configuration hierarchy. This allows for greater control and accuracy. On the other hand, if the configurations are too granular, the system can become a collection of small configurations with no relationships established between each other. For example, when defining a large 3745 network, we first define the lines, along with their drops, as separate configurations, then connect these lines to the 3745 in another configuration. This logic can be applied to other layouts as well, including the client/server arena. Although the industry direction is to automate network asset control as much as possible, managing the entire configuration does not necessarily have to be automated from the start; especially within the enterprise. It is our primary purpose to reduce the amount of manual work and the possible human errors typically found in current network configuration and asset management processes. Therefore, the technique presented here does not provide the Company with the complete automation process for the entire enterprise configuration. Rather, we recommend that you begin the initial steps for replacing much of the tedious work of entering and updating configuration data manually. 1.3.6. 1.3.6. Data Requirements for Inventory Management To ensure a consistent, centralized and integrated control, as described in the previous section, a common data model must be built. This will ensure a

- 30. consistent reporting process to the inventory data base regardless of where the data is stored. In the event of incomplete record information, the inventory management area must re-solicit, or advise the responsible asset area of the missing data elements. This reentrant approach provides a disciplined strategy to build a reliable inventory. The structure illustrated in the next diagram allows the description of hierarchical relationships among data centers, systems, components, service organizations, and financial data. By entering descriptions of the hardware and software system components, along with information about their status and support data, a data base can be built which supports parent/child relationships. The figure on the next page shows the interrelationship between component records: 1.3.7. 1.3.7. Inventory Management Data Model Inventory Management Data Model Data Center Record System Record Hardware Service Software Component Record Component Features Features Hardware Software Financial Financial Record Record

- 31. Figure 7: Inventory Management Data Model The following items are required from asset sources to support an integrated Configuration Management approach. 1. Data Center Record. This record contains on-line information about the data processing centers, the system name, location codes, emergency phone numbers, managers, and contact names. The software and hardware components, and system records will refer to this record. 2. System Record This record contains information relative to each processing system within the processing center. This record should contain the system names by LPAR, location codes, operator names, support numbers. Software and hardware components can refer to this record. 3. Service Record This record contains the service organization’s data. Maintaining service organization records is advantageous when a user is displaying a record of a failing component. This record should contain the name, location, prime-shift phone number, off-shift phone number, hardware and software representative’s name, and contact phone numbers, and a description of the service organization. Hardware and software components can refer to this record. 4. Financial Record Helpful information in this record assists in warranty and service incidents. Hardware financial records contain a user financial id, a financial type, and a description. For software records the same information is required in addition to a license type record entry. 5. Hardware Components For hardware component records a consensus must be reached on the hardware types to be managed. A hardware model record for each hardware type will be created and all common hardware components will be entered using this template. This record should contain the following information: Component ID, Product Number Serial Number,

- 32. Generic device type, Model, Manufacturer, Owner, Install Date, Location, Maintenance Vendor, Contract type, Component status, Component Criticality Component description. In some instances a hardware subcomponent record must be entered. A subcomponent can be thought of as a feature that can be a stand-alone component and has mobility in the inventory (for example, 3726, 3727, external hard disks). This will allow subcomponents to be removed or moved from their hardware component or attached to another component. This record should contain a subcomponent status code and a description. 6. Software Components For software component records a consensus must be reached as to what level of installed software will be within the scope of the asset data base. For example, is the workstation (PC-based) software to be managed? If so, are we to account for all application software or just operating system software? The answers to these questions are linked to what kind of information the user support groups require to provide service to the client. In a centralized Help Desk environment, all user application software, including maintenance levels, are maintained. This provides up-to-date information to the Help Desk personnel about the user environment and adds greatly to their productivity. A software model record for each component contains an ID, maintenance level, program type, status and a description. A typical software record should contain the following information: System (application runs on), Product Number Name, Model, Vendor, Serial Number, Renewal Date, License Type, Contract Type, Maintenance Level,

- 33. Description. 7. Feature Components Record This record identifies associated features and relates these features back to other records. 8. Model Component Record The industry uses this type record as a productivity tool to greatly enhance the ability to build large data bases quickly with minimum data entry errors. Model records themselves do not hold configuration data, but they make the entry of data easier by allowing the creation of component records from models that hold information common to a number of components (or subcomponents) of the same type. The model capability also provides the ability to build one or many relationships between model features and hardware or software components. Features that are common to many components can be contained in a single model feature record that is referred to by many component records.

- 34. 1.3.8. 1.3.8. Collecting, Monitoring and Reporting Data 1. Monitoring and Reporting Data Once the inventory data base has been built it will be used to satisfy the following requirements Determine bypass and recovery procedures when a failing component has been identified. Determine the level of a component, and also other components that are affected when a problem occurs. Establish relationships between a component and any problem or change record in the data base. Search for any components meeting specific characteristics, such as all terminals in a network and the locations to which they are assigned. Generate reports on specific configuration information, including but not limited to the following: - Hardware or software components with related features, - Physical inventory by location, - Hardware and software configuration maps, and - Service reporting for maintenance contracts, warranty, and invoice tracking. 2. Collecting Data The Record Hierarchy in the following diagram indicates that component records refer t data center, system, service, and financial records. These four records are informational components. This means they must be created prior to creating the component records (hardware, software). It saves time because these records must be defined before they can be referenced in component records. This allows you to establish connections as you create the records. 1.3.9. 1.3.9. Inventory Management Record Hierarchy

- 35. Inventory Management Record Hierarchy Center, System, Service and Financial records must be created before you can reference them in the Center System Service Financial component records Hardware / Software Hardware / Software Component Model Component Direct You can create a component from a Model record Hardware Subcomponent Model Record link relationship to Component hardware component record. Component Hardware / Software Hardware / Software Parent / Child Parent / Child Relationship Relationship Model Feature Feature Connection Subcomponent Model etc. Hardware / Software Parent / Child Hardware / Software Relationship Figure 8: Inventory Management Record Hierarchy

- 36. 1.4. 1.4. Discipline Relationships To ensure the integrity of the process, Inventory Management must interface with multiple business and I/S system management functions. The interface to these functions provides the foundation for strong Inventory Management practices. 1.4.1. 1.4.1. Business Function Interfaces Some of the more common business functions that interface with Inventory Management include: Purchasing This resource manages all information systems requirement identification through the procurement process. Inventory Management provides input to Purchasing in terms of system and network standard asset information. Accounts Receivable / Payable Department This function collects usage data and bills information System (I/S) expenses to the appropriate users. It supports accounting, budget planning, tracking of project costs, and other activities. Inventory Management provides financial records as input to the Accounts Receivable / Payable process and vice versa. This two-way interface occurs with the approval and submittal of billings for payment. I/S Management Committees These groups investigate tools and services to provide policy information and translate that data into recommendations for I/S productivity improvements and services. Inventory Management will provide input to these groups in terms of product standards and technology strategies. Strategic Planning Committees These groups deal with long-range planning and the integration of I/S objectives with the business objectives of the enterprise. Inventory Management provides an interface to Strategic Planning by providing insight into device migration patterns, trends, and direction, and the Strategic Planning Committees provide information back to the disciplines as well. Security Department

- 37. This function manages the registration or enrollment of people and programs to access controlled I/S resources. Inventory Management provides input about device configurations and security interfaces to this functional area. User Support Groups Since these groups are responsible for their equipment acquisition, they must be compliant with the inventory process. Tracking the acquisition of network and computer equipment at the local level can be difficult without their full participation. To ensure accountability of such purchases, provisions should be made for a periodic physical inventory of such groups to ensure a level of inventory integrity. Client Support Services These groups define the services that will be needed to support the I/S clients within the enterprise. Within Services Management are two key areas: 1. 1. Help Desk - This area provides a single point of contact for clients to request services and obtain resolutions for problems. 2. 2. Service Level Planning - this area identifies the agreement between the I/S organization ad the user community that defines the level of service. The service level agreement is also used to define policies for operations and performance management.

- 38. 1.4.2. 1.4.2. System Management Interfaces The Inventory Management discipline is dependent upon various disciplines and functions within the enterprise in achieving its objectives. These disciplines and functions and the assumptions related to their tasks are listed below: Change Management Coordinates the various tasks performed in configuration change and testing across the data processing environment. Any changes to the I/S environment that affect Inventory Management are input from this discipline. Problem Management Assists the I/S organization in locating, identifying, and resolving inventory problems. The Problem Management discipline will provide input to Inventory Management as problems arise that require changes to resolve conflicts. Facilities Planning Required to participate in the Problem or Change process as they pertain to the physical environment and is accountable for any actions required to comply with the inventory management process. It is essential that this group provide input to Inventory Management and vice versa, to ensure changes in physical asset configurations are noted.

- 39. 1.5. 1.5. Inventory Management Tools Inventory Management uses network definition information, Vital Product Data (VPD), local configuration data bases and, in some cases, discovery applications in order to arrive at inventory information. The following list of Inventory Management tools was accumulated after conducting a general survey of large corporations in the area. The participants represented large corporations with an annual I/S budget of over $100M. The survey solicited information about how they performed Problem, Change, and Inventory Management and what techniques and tools were used to accomplish tasks in the two areas that follow. Those products which are specifically mentioned were approved by the vast majority of participants. We also list major Inventory Management functions that can be fulfilled by any number of products, but do not specifically mention a product by name. 1.5.1. 1.5.1. Asset Management at the System to Server Level The major components that provide the collection and reporting vehicles for Inventory Management from the system level out to the network server level include: VTAM and NetView VTAM and some specialized features of NetView are responsible for maintaining the necessary linkages to the physical asset, whether it is within the system complex or out to the server level on the network. Centralized Data Bases All assets and their associated information are stored in a centralized data base. Editing and browsing capability are available through an on-line menu driven, front-end that provides restricted security access, if necessary. This security is provided through any number of host-based security packages. Network Configuration Application (NCA) / MVS NCA/MVS is a useful tool for migrating existing stand-alone (PC-based) inventory control data bases to host-based formats. It should be noted that in some cases conversion utilities have been written to convert these stand-alone environments into a data base file structure. Enterprise Physical Connection Tool (EPCT)

- 40. EPCT is a useful product for building configuration data bases and producing physical and logical diagrams. The figure below illustrates the usage of these tools within the process. Asset Management at the System to Server Level Creates Configuration Drawings NCS / MVS Creates Configuration Drawings EPCT Data Base Repository for all Assets (Mainframe through Centralized Data Network) Asset Data Bases VPD CMDS Collect Data NetView Status Monitor - VTAMLST VTAM NETVIEW AUTOBRIDGE * Alert / Problem Reporting Remote Controller 3174 * Automated / Manual Bridge * Serial Number Remote to Info/Man * Type / Model Controller P - Primary Connection P S S - Secondary Connection Remote Terminal * Serial Number * Type / Model Figure 9: Asset Management at the System to Server Level 1.5.2. 1.5.2. Industry Standards Centralized Inventory Data Base Repository The industry uses any number of system management products which integrate the entry of Problem, Change, and Inventory Management into a common, centralized data base repository. However, these integrated products must interface to the tools listed below to facilitate the automation ad centralization of an asset management data base repository. VTAM Version 3.4 (Planning and Reference Guide - SC31-6124)

- 41. VTAM Version 3.4 is a telecommunication access method that works in conjunction with MVS/ESA Version 4 to support non-disruptive addition of channel-connected communications controllers and SNA cluster controllers. NetView Ver. 2 Rel. 3 (User’s Customization Guide - SC34-4336) Network Manager which will provide: 1. NetView Bridge Adapter (NetView Bridge Adapter Reference - SC34-4336) A component that provides a set of application-to-application interfaces that will provide an effective means of connecting NetView to external data bases. 2. Status Monitor Function Collects status information about SNA resources such as hardware data (from VTAMLST) and reports to a centralized data base. 3. NetView Autobridge Version 1 (User’s Guide - SC34-4318) NetView Autobridge will allow the flow of configuration and change data from NetView to a centralized Data Base Repository. 4. RODM - Resource Object Data Manager The Resource Object Data Manager will provide services that enable systems and network management. The facility is used by NetView’s multi-vendor graphic enhancement and automation platform. These services will be used to create configuration drawings of the asset data base. 5. Network Configuration Application/MVS (NCA/MVS) Version 1 (User’s Guide - SC31-6149) Network Configuration Application/MVS is a configuration application for use on an MVS platform. It provides for collection of information about equipment, circuits and software; has the ability to create configuration representations for components in all types of network topologies; and allows for creation of abstracts to represent relationships of components. A utility function transforms this data into the format required by the Resource Object Data Manager Facility in NetView Version 2 Release 3 for graphic views. 6. Enterprise Physical Connection Tool (EPCT) (User’s Guide - SC23-0546) This DB2-based asset collection and physical drawing product will provide the capability to draw physical and logical topologies of system and network complexes. EPCT is a locally developed

- 42. application written by the ISSC Corporation in C Language and provides browsing an editing capability on-line. This product can be ordered as an PRPQ through the IBM Corporation.

- 43. 1.5.3. 1.5.3. Downstream Network Server Configuration and Inventory Management The following figure illustrates a downstream view of Network Configuration and Inventory Management. Downstream Network Server and inventory Management Data Base Repository Centralized Configuration INDUSTRY PENETRATION Data Base PVCS - INTERSOLV VPD DMDS Collect Data NETVIEW LANFOCUS - IBM Status Monitor - VTAMLST VTAM Machine Serial Number WAN SERVER Model / Type Automation Stops at the Server Level AUTOMATED MANUAL This Layer Requires Additional Software To Support Configuration Management Figure 10: Downstream Network Server and Inventory Management Asset management below the server level has not been widely implemented throughout the industry today. WAN environments have their own unique challenges. Most host- based products require an additional layer to bridge beyond the server level. The products listed below are seeing some industry penetration and promise to be viable tools in the coming months ahead. PVCS Configuration Builder Series (Product of INTERSOLV Corporation) The PVCS series covers all key functional areas for configuration management: Version Management,

- 44. Build Management, release Management, and Report Generation. These functional areas are available across all types of files including source code, text, or documentation files, graphic or binary files. With PVCS Series development teams can: Recreate a system, or component of a system at any time and prevent inadvertent errors and code changes with version management. Rebuild an entire system when any component is changed without having to remember complete relationships about elements of the system. LANFocus Management / 2 (Product of the IBM Corporation) This family of products provides System Management principles to LAN attached workstations having OS/2 and DOS installed. The products provide a platform which includes a programming interface for the creation of system management applications. This includes applications which address the disciplines of problem management, performance management, and configuration management.

- 45. 1.6. 1.6. Roles and Responsibilities 1.6.1. 1.6.1. Inventory Manager Responsible for maintaining the Inventory in a current and accurate state. Role is responsible for both mainframe and network resident devices and software components. Interfaces with Systems Management disciplines and Financial department. 1.6.2. 1.6.2. Inventory Clerks Responsible for maintaining the Inventory Data Base Repository and for guarantying the information contained within the Repository is accurate and in a current state. Information is data entered, or entered via automated tools. If automated tools are used, then clerks must be knowledgeable in program products used as a tool.

- 46. 1.7. 1.7. Process Evaluation 1.7.1. 1.7.1. Present System Weaknesses There is presently no Centralized Repository for asset information, because Inventory Management is performed by many various groups (i.e., mainframe, communications, data network, etc.). A consolidation of these data bases into a centralized Inventory Repository should be planned. When migrating to a centralized repository, automated tools and interfaces should be developed, so that any acquisition, redeployment, or termination of assets will have to accomplished through the automated system. This will reduce the effort presently performed by personnel and guaranty the accuracy of the Inventory repository. 1.7.2. 1.7.2. Recommendations for Improvement Create a Centralized Repository of Inventory information. Utilize Automated Tools and Front-end to the Inventory Repository. Integrate the Inventory Repository with the everyday asset functions performed by personnel, such as: Asset Acquisition, Asset Redeployment, Asset Termination, Lease and Contract Maintenance, Volume Purchase Agreements, etc. Utilize a “Criticality” indicator to relate assets and their criticality for disaster recovery purposes. This will allow for reports that list all most critical resources for a specific location, by type and costs. Formulate a committee to investigate methods for improving Inventory Management and implement the most rewarding suggestions from the committee.