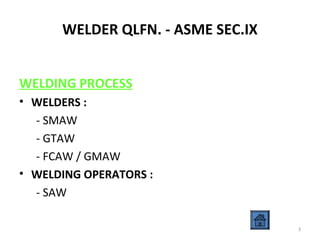

This document provides information on the essential variables and requirements for welder qualification according to ASME Section IX. It lists the key variables that must be specified for a welder qualification, including welding process, type, base metal, filler metal, and weld thickness limits. It also outlines the qualification requirements and limitations for weld position, diameter, progression, backing, and which filler and base metals a welder is qualified to use based on their test.

![9

WELDER QLFN. - ASME SEC.IX

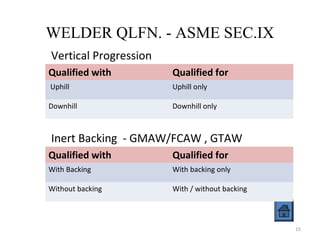

Weld Thickness in Qualification Test

[t in inch (mm)]

Less than 1/2 (13)

1/2 (13) and over

GROOVE

Maximum Qualified Weld Thickness

[inch (mm)]

2t

Unlimited

OVERLAY

Qualification Test Thickness

[T in inch (mm)]

Thickness Qualified

[inch (mm)]

Upto 1 (25) T to unlimited

over 1 (25) 1 (25) to unlimited](https://image.slidesharecdn.com/welderqualification-130506031100-phpapp02/85/Welder-qualification-9-320.jpg)

![12

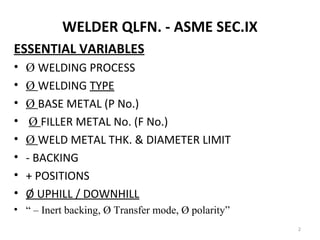

PERFORMANCE QUALIFICATION- POSITION AND DIAMETER

LIMITATIONS

NOTE: (1) Pipe 2 OD and over.7/8

1G

2G

3G

4G

3G and 4G

2G,3G,and 4G

1G

2G

5G

6G

2G and 5G

Plate and

Pipe

Over 24 in.O.D.

Pipe

<= 24 in. O.D.

Plate and Pipe

Groove Fillet

Position and Type Weld Qualified

Weld Position

Pipe-Groove

ALL

ALL

F

ALL

ALL

ALL

F,H

F

F,H

F,H,V

F,H,O

ALL

F,V,O

F

F,H

ALL

F

F,H

F [ Note (1) ]

F,H [ Note (1) ]

F,V,O

ALL ALL

F [ Note (1) ]

F [ Note (1) ]

F [ Note (1) ]

F,H [ Note (1) ]

F,O

F,V,O

ALL

F

F,H

F,V

Qualification Test

Plate- Groove](https://image.slidesharecdn.com/welderqualification-130506031100-phpapp02/85/Welder-qualification-12-320.jpg)