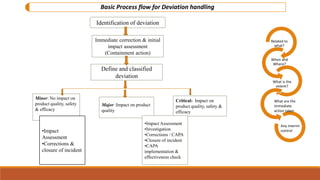

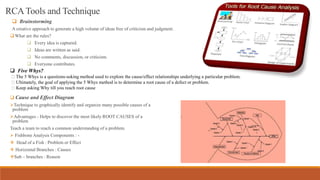

This document discusses deviation handling and root cause analysis. It defines deviations as departures from standard procedures and outlines regulatory expectations to investigate deviations and prevent reoccurrence. The basic process flow for handling deviations includes identification, assessment, classification, investigation and corrective actions. Root cause analysis is presented as a method to systematically identify underlying causes of problems using techniques like brainstorming, 5 whys, and cause-and-effect diagrams. The goals of root cause analysis are failure identification, analysis, and resolution through an iterative process.

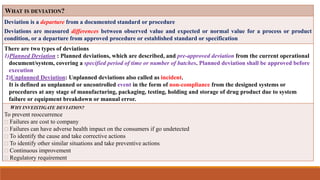

![Regulatory Expectation

• “Any unexplained discrepancy…shall be thoroughly investigated…The

investigation shall extend to other batches …that can have been associated with the

specific failure or discrepancy. A written record of the investigation shall be made

and shall include the conclusions and follow-up

21 CFR 211.192

•“Any deviations from instructions or procedures should be avoided as far as

possible. If a deviation occurs, it should be approved in writing by a competent

person…”

• Any significant deviations [from defined procedures and instructions] are fully

recorded and investigated

EC Guide to GMP, Chapter 5

(5.15)

• Any deviation from established procedures should be documented and explained.

Critical deviations should be investigated, and the investigation and its conclusions

should be documented.

ICHQ7A

• The organization should ensure process outputs, products, and services that do not conform to

requirements are identified and controlled to prevent unintended use or delivery. The

organization should take appropriate action based on nature of nonconformity and its impact on

conformity of products and services. This is applicable also to nonconforming products and

services detected after delivery of products during or after provision of service

ISO 9001:2015,Clause 8.7

When a deviation occurs the responsible firm must undertake and investigation to determine what went wrong

and what damage, if any , the product might have suffered.](https://image.slidesharecdn.com/deviationandrootcauseanalysis-170225131302/85/Deviation-and-root-cause-analysis-in-Pharma-3-320.jpg)