Gas Turbines O&M-Trainer Rev 01.pdf

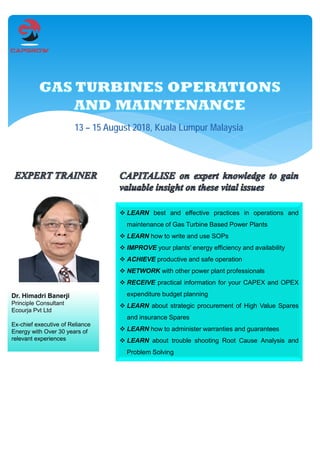

- 1. 13 – 15 August 2018, Kuala Lumpur Malaysia LEARN best and effective practices in operations and maintenance of Gas Turbine Based Power Plants LEARN how to write and use SOPs IMPROVE your plants’ energy efficiency and availability ACHIEVE productive and safe operation NETWORK with other power plant professionals RECEIVE practical information for your CAPEX and OPEX expenditure budget planning LEARN about strategic procurement of High Value Spares and insurance Spares LEARN how to administer warranties and guarantees LEARN about trouble shooting Root Cause Analysis and Problem Solving Dr. Himadri Banerji Principle Consultant Ecourja Pvt Ltd Ex-chief executive of Reliance Energy with Over 30 years of relevant experiences

- 2. The aims of the O&M of Gas Turbines Workshop is to share the experiences of our internationally renowned expert with an aim to prevent such incidents and also to examine the factors and opportunities to increase plant safety, environmental performance. And improve uptime and availability all factors contributing to higher profitability. The workshop will also examine scheduled maintenance and turnarounds which are opportunities to increase plant safety and environmental performance. By enhancing the mechanical integrity of HPI facilities, operating companies can achieve and maintain higher uptime and equipment availability; all are factors that contribute to higher profitability. Best-of-class companies hold the mindset that reliability programs provide great benefits. Investing in new monitoring and conditioning systems, along with preventive maintenance and inspection programs, can optimize unit and total facility performance. The development of dry low NOx (DLN) combustors for gas turbines has cut the industry's consumption of water, while dramatically slashing air emissions. Unfortunately, this environmental enhancement has created an engineering challenge: The lean-burning DLN combustors are prone to flame instability, which can cause pressure pulsations large enough to destroy the combustor, launching debris downstream where it annihilates other hot-gas-path components. To detect and correct flame instability before it causes millions of dollars of turbine damage, savvy users have begun to install advanced sensors and robust software that monitor the combustor dynamics in real time. High dynamics can limit hardware life and/or system operability. Thus, there have been various attempts to control combustion dynamics, to prevent degradation of system performance. There are two basic methods for controlling combustion dynamics in an industrial gas turbine combustion system: passive control and active control. As the name suggests, passive control refers to a system that incorporates certain design features and characteristics to reduce dynamic pressure oscillations. Active control, on the other hand, incorporates a sensor to detect, e.g., pressure fluctuations and to provide a feedback signal. Which, When suitably processed by a controller, provides an input signal to a control device. The control device in turn operates to reduce the dynamic pressure oscillations. The workshop will examine the factors and the issues associated with combustor dynamics, and technologies like AMFM/CFM. Our Expert Dr. Banerji has decades of experience on management models, working methods and power plant O&M business process development in order to achieve successful results in operations. His model of training is based on his long-term work. He has successfully reduced operation cost of many power plants by efficient performance and improvements in energy efficiency and availability. Session 1: General Overview of Gas Turbines 1.1 Introduction 1.2 Frame type heavy-duty gas turbines 1.3 Industrial type gas turbines 1.4 Aircraft derivative gas turbines 1.5 Comparison between aircraft-derivative and industrial heavy-duty turbines 1.6 Small and micro gas turbines 1.7 Aircraft gas turbines 1.8 Gas turbine components Session 2: Fundamental Gas Turbine Cycle Thermodynamics 2.1 Reversible cycles with ideal gases 2.2 Constant pressure or Brayton cycle 2.3 Ideal inter-cooled and reheat cycles 2.4 Actual gas turbine cycles 2.5 List of terms and symbols used Session 3: Gas Turbine Components 3.1 Compressors 3.2 Centrifugal compressors 3.3 Axial-flow compressors 3.4 Compressor theory 3.5 Compressor aerodynamics 3.6 Common problems affecting axial compressor operation and performance 3.7 Air compressor performance characteristics 3.8 Combustors 3.9 Combustor performance and efficiency 3.10 Turbines 3.11 Fuel nozzles and igniters 3.12 Emission control Course Agenda (Day 1 – Day 3)

- 3. Session 4: Materials of Construction 4.1 Introduction 4.2 General metallurgical behavior in gas turbines 4.3 Gas turbine blade materials 4.4 Blade manufacturing techniques 4.5 Future materials Session 5: Bearings and Seals 5.1 Bearing materials 5.2 Through hardened materials 5.3 Case hardened materials 5.4 Cage materials 5.5 Babbitts 5.6 Bearing design principles 5.7 Tilting-pad journal bearings 5.8 Design of thrust bearings 5.9 Seals Session 6: Lubrication System in Gas Turbines 6.1 Introduction 6.2 Oil reservoir 6.3 Pumps and oil jets 6.4 Lubrication oil filters 6.5 Oil coolers 6.6 Relief valves 6.7 Lubricant selection 6.8 Oil system cleaning and conditioning 6.9 Filter selection 6.10 Oil sampling and testing Session 7: Fuels and fuel supply systems 7.1 Introduction 7.2 Fuel specifications and fuel properties 7.3 Other important fuel properties 7.4 Fuel treatment 7.5 Economics of fuel selection 7.6 Gas fuels 7.7 Heavy fuels 7.8 Comparative fuel costs 7.9 Cleaning of turbine components 7.10 Fuel supply and control systems 7.11 Dual-fuel operation and operational flexibility 7.12 Integrated gasification combined cycle Session 8: Sound Suppression in Exhausts, Air Requirements and Environmental Considerations 8.1 Noise from gas turbine engines 8.2 Aircraft sound suppression methods 8.3 Air requirements and environmental considerations Session 9: Auxiliary Systems 9.1 Starting systems 9.2 Fuel washing systems 9.3 Gears 9.4 Gear design and performance parameters 9.5 Couplings and shaft alignment 9.6 Shaft alignment Session 10: Performance and Mechanical Equipment Standards 10.1 Introduction 10.2 Performance standards 10.3 Mechanical standards Session 11: Control Systems and Instrumentation 11.1 Control systems 11.2 Startup and shutdown considerations 11.3 Control of the equipment during operation 11.4 Lifecycle costs 11.5 Condition monitoring systems and their implementation 11.6 Temperature, pressure and vibration measurement 11.7 Campbell diagram 11.8 Gas turbine performance measurement and calculations 11.9 Protection systems and alarms 11.10 Failure diagnostics Session 12: Installation Requirements, Operation and Maintenance 12.1 Installation requirements 12.2 Philosophy of maintenance 12.3 Maintenance techniques 12.4 Maintenance of critical gas turbine components 12.5 Maintenance planning and scheduling 12.6 Spares and inventory management 12.7 Maintenance tools 12.8 Inspection 12.9 Gas turbine overhaul and repair 12.10 Training 12.11 Training types 12.12 Typical problems 12.13 Health monitoring in gas turbines 12.14 Troubleshooting in gas turbines 12.15 General troubleshooting techniques for compressors, combustors and turbines 12.16 Evaluation of the effectiveness of gas turbine maintenance Program Schedule (Day 1 - Day 3) 08:30 Registration 09:00 Morning Session Begins 10:40 - 11:00 Refreshments & Networking Break 12:45 Luncheon 14:00 Afternoon Session begins 15:30 - 15:50 Refreshments & Networking Break 17:30 Course Ends In-house Training This course can be presented exclusively for your organisation on an in-house basis, tailored to meet your specific needs, at a place and time of your convenience. Contact us to find out more: Email: info@capgrow.com.sg Tel: +65 6612 1954 Fax: +65 6722 8610

- 4. Presently from 2014- continuing working on a prestigious International Assignment funded by JICA assisting Ernst and Young Inc. as an International Expert Gas Turbines for Capability Building in Management of Gas Turbine Based Combined Cycle Power Projects and their Operations in Electricity Generation Company EGCB of Bangladesh. To improve capabilities of technicians, engineers, managers and directors in managing O&M of a 412 MW MHI Gas Turbine based Combined Cycle Power Plant. Imparting training, developing modern O&M Processes, SOPs, O&M Manuals, Conducting Workshops etc. With the training the staff will be able to design effective operations and maintenance strategies for the plant, based on professional assessment of the critical plant equipment. We will train the staff to develop monitoring programs to in maintaining the asset value and by assisting client in deploying and training personnel and state-of-the-art management tools and processes, like trouble shooting, Root Cause Analysis, Problem Solving, Risk Analysis etc to promote safe, reliable and efficient plant operations. The processes will be designed based on world renown asset management standards, which is being adopted by many leading edge corporations in the world. As a part of the assignment our expert Dr Banerji has provided… • Training of senior management on organization design, defining key result areas and key performance indices of managers, engineers and staff. • Training on station performance measurement, and improvement • Training on how to planning work during shutdowns, • Maintenance turn-around project monitoring and control • Monitoring repairs and reverse engineering activities at third party repair companies • Training in Steam and Water Chemistry, Deposit and Corrosion Control, in Heat Exchanger, Cooling Towers, Condensers and Cooling Water Systems • Training in Fuel Management, Combustion, Quality Control and Measurement. • Also train senior and middle management on critically assessing repair options and procedures including coating selection, fully identifying and understanding the failure processes with identifying proper processes to prevent recurrence in future bringing together with imparting the knowledge of materials, design of components, conducting through forensic investigation. • Training of officers involved in arbitration and litigation and insurance claims. • Training on how to organize international consultants for independent audits of maintenance practices, Dr. Himadri has over 30 years of relevant experiences. He served as general manager for Rolls Royce in India for three years, and he was in charge of the gas turbines design, manufacturing and quality control. After that he spent another two years with Gujarat Industries Power Company Limited, he was the executive director and responsible for the operation and maintenance of existing gas turbines power plants as well as the start up and commissioning of new ones. He then moved to Torrent Power as the executive director for operations, for five years there he was in charge of the Organization, planning, staffing and supervising of operation and maintenance of the power plat fueled by gas and retrofitted Naphtha. At last but not the least, he joined Reliance Energy as the chief executive, he spent six years there, and his main role was training the officers and staffs in the fields of gas turbine operation, repairs and maintenance, trouble shooting, failure analysis, reengineering, document control, maintenance of records etc; as well as the senior and middle management on critically assessing repair options and procedures including coating selection, fully identifying and understanding the failure processes with identifying proper processes to prevent recurrence in future bringing together with imparting the knowledge of materials, design of components, conducting through forensic investigation About Our Expert Trainer Who Should Attend and Why You Should Attend Training modules are planned for Gas Turbines power plant managers, and persons responsible for operation & maintenance or O&M production. It is also suitable for persons who want to upgrade and expand their knowledge in this field. By attending this course, you will be able to: • Learn best and effective practices in operations and maintenance of Gas Turbine Based Power Plants • Learn how to write and use SOPs • Improve your plants’ energy efficiency and availability • Achieve productive and safe operation • Network with other power plant professionals • Receive practical information for your CAPEX and OPEX expenditure budget planning • Learn about strategic procurement of High Value Spares and insurance Spares • Learn how to administer warranties and guarantees • Learn about trouble shooting Root Cause Analysis and Problem Solving