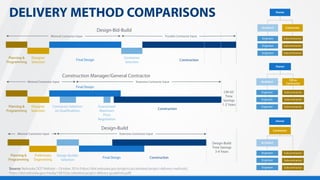

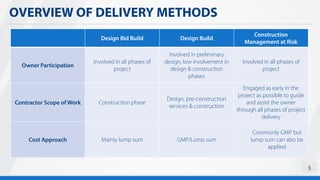

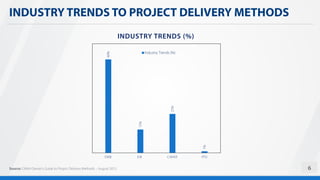

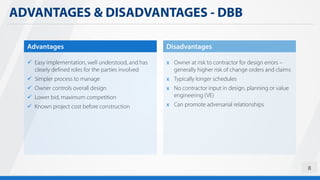

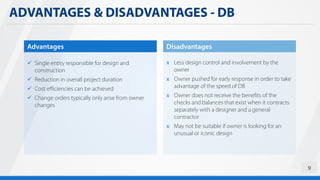

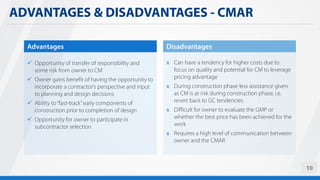

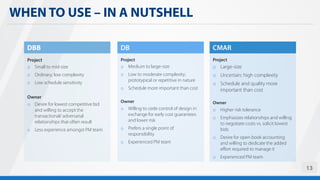

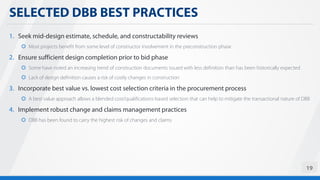

The document provides an overview of project delivery methods including Design-Bid-Build (DBB), Design-Build (DB), and Construction Management at Risk (CMAR), with definitions, advantages, and disadvantages of each. It also offers guidance on when to use each method based on factors such as project size, complexity, and owner involvement, and presents best practices for managing projects under these methods. The document concludes with a brief introduction of PMA Consultants and their expertise in project management.