DESIGN AND FABRICATION OF AUTOMATED CRADEL MACHINE

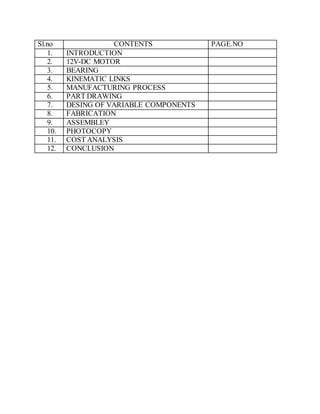

- 1. Sl.no CONTENTS PAGE.NO 1. INTRODUCTION 2. 12V-DC MOTOR 3. BEARING 4. KINEMATIC LINKS 5. MANUFACTURING PROCESS 6. PART DRAWING 7. DESING OF VARIABLE COMPONENTS 8. FABRICATION 9. ASSEMBLEY 10. PHOTOCOPY 11. COST ANALYSIS 12. CONCLUSION

- 2. 1.INTRODUCTION: In our project, we are mainly concerned about the needs of the common family. It is mother, who plays vital role in taking care of babies. Taking a baby to sleep is a tedious process. If it is not carried out in a proper way, then the whole family has to accompany with the baby for full night. At present, the cradle (or) swing is essential for the baby’s sleep. But it is such an enormous duty for the mothers. This paves a way for weakening of strength, stress, depression for them. This brings chaos and unpleasant atmosphere at home, living of many families proved it right. The allergy of swinging the cradle is prevailing in most families, where both parents are employees. This injects the grievance between the couple. To bring a solution to these, a baby cradle is designed. This baby cradle is a typical model that resembles the traditional model which is fixed over the tree branches. This baby cradle operates electricallyat low power. For the convenience of the parents, it can be operated by remote. Can be switched –off if not necessary. It consists of various features including speed variation, automatic sensing and can be operated manually too. In these ways, this cradle pleases the mothers. This device reduces the major part in the art of baby caring. And we hope that our model will bring a pleasant atmosphere and an adorable maternal-child and a family environment.

- 3. 2. 12-V DC MOTOR Item specifications standard: 30W 12V Voltage: 12V Motor: Brush Type: DC Motor Braking torque: 26N/m Working torque:5N/m Working speed: I. Non- load speed: Min-35 rpm Max-52 rpm II. With load-30 to 45 rpm Use: Wiper color: black painted gear material: aluminium Application: ZD1332 / ZD2332 Lifting motor material: stainless steel Wiring: 2/4 wires Specifications 1. Low noisy with high technical 2. OE quality 3. CE ISO9001 TS16949 FUNCTION 1.20W 12V wiper motor for Medical Equipment Motor 2. OEM Quality 3. Producing various wiper motors under your required parameter. 4. ISO9001:2000 ,ISO/TS16949:2002 international quality management system certification. 5. Repairs can be easilydiagnosed. 6. The quality is reliable.And the product is tough and durable.

- 4. 3. BEARING A bearing is a machine element which supportanother moving machine element (know as journal) it permits a relative motion between the contact surface of the member of the members while carrying load. NECESSITYOF BEARING: To reduce the amount of power wasted in overcoming frictional resistance To prevent the wear of rotating components. CLASSIFICATION OF BEARING Direction of load to be supported Radial bearing Thrust bearing Nature of contact Sliding contact bearing Rolling contact bearing TYPES OF ROLLING CONTACT BEARING: Ball bearing : Balls are placed between inner and outer races. Roller bearing: Rollers are placed between inner and outer races.

- 5. TYPES OF RADIAL BALL BEARING Single row deep groove bearing: This type is used for carrying high load and for high running speeds. Filling notch bearing : Since this type of bearing contains larger number of balls than a corresponding unnotched one therefore it has large bearing load. Angular contactbearing: This bearing carries a relatively large axial load in one direction while also carrying a relatively large radial load. Double row bearing : The load capacity of this type is slightly less than twice that of a single row bearing. Self aligning be these bearing permits shaft deflection within 2° − 3°. MATERIAL : The balls are generally made of high carbon chromium steel. The material of both the ball and races are heat treated to give extra hardness and roughness.

- 6. LUBRICATION: To reduce friction and wear between the rolling parts of bearing . To prevent rusting or corrosionof the bearing surfaces. To protect the bearing surfaces from water ,dirt ,etc To dissipate the heat. ADVANTAGES OF ROLLING CONTACT BEARING: Low starting and running frication except at very high speed. Ability to withstand momentary shockloads. Accuracy of shaft alignment. Low costof maintenance as no lubrication is required while in service. Reliability of service. DISADVANTAGES: Designing of bearing housing complicated. Low resistance to shock loading. More initial cost.

- 7. 4. KINEMATIC LINKS OR ELEMENTS Introduction: A machine consisits of a number of parts or bodies. We shall discuss the mechanism of the various parts of the bodies from which the machine is assembled. This is done by making one of the part is fixed and the relative motion of other parts is determined with respect to the fixed part. Kinematic link or element: Each part of the machine which move relative to the some other part is known as kinematic link or element. A link may consist of several parts which are rigidly fastened together so that they don’t move relative to one another. For example, in a reciprocating steam engine, piston , piston rod, & cross head constitute of one link. Connecting rod with bis and small ends and bearings constitute a second link, crank, crank shaft, flywheel are in third link and the cylinder, cylinder engine frame main bearing are in fourth link. Resistant body: A link or element need not to be a rigid body, but it must be a resistant body. A link should have a two characters given below: It should have relative motion. It must be a resistant body.

- 8. Types of links: Rigid link Flexible link Fluid link. In our project, we use only Rigid Links. Rigid links: A Rigid link is one in which does not undergo any deformation, while transmitting a motion. As the deformation of the connecting rod, crank etc.,. of a reciprocating steam engine is not applicable, thry can be considered as a rigid link. Structure: It is a of number of resistant body(known as members) have no relative motion between them and meant for carrying load having straining action. Kinematic pair: The two links or element of a machine when in contact with each other they are said to form a pair, if the relative motion between them is completely or successfully constrained pair is known as kinematic pair. Classification of kinematic pairs: Sliding pair Turning pair Rolling pair Screw pair

- 9. Spherical pair In our project, we are mainly concerned about the sliding pair, rolling pair and screw pairs only. I. Sliding pair: When the two elements of a pair are connected in such a way, that one can slide relative to another. II. Rolling pair: When the two elements of a pair are connected in such a way, that one can roll over another fixed link is known as rolling pair. III. Screw pair: When the two elements of a pair are connected in such a way, that one element can turn about other by screw threads is known as screw pair.

- 10. 5. MANUFACTURING PROCESS MANUFACTURING PROCESS CHART PRIMARY CUTTING PROCESS MACHINING PROCESS SURFACE FINISHING PROCESS OPERATIONS INVOLVED Facing Drilling Gas cutting Shaping Welding Revetting Thread cutting ASSEMBLING PROCESS

- 11. FACING Machining the end of the workpiece to produce flat surface is called facing. Due to this, the plate can get flat surface have done by facing operation. DRILLING Drilling is operation of producing cylindrical hole in the workpiece. It is done by rotating the cutting edge of the cutter known as drill bit. In our project the drilling is done on the clamp for inserting the bolt and screw rod. SHAPING The process of shaping the job for required dimension using shaping machine is known as shaping. This is done in the MS plane to make steps. WELDING The process of joining two similar or dissimilar metals is known as welding. It is done between the steps and base. THREAD CUTTING Thread cutting is the operation of forming external thread of required

- 12. diameter of rod by using a multipoint tool is called thread. This process is used in strap clamp to done on the rod which is used for the movement of the clamp up and down. MANUFACTURING PROCESS PRIMARY CUTTING PROCESS The process used for preliminary cutting of the component are known as primary cutting process . The common operations involved in this process are gas cutting , sawing etc. MACHINING PROCESS The process used for giving final shape to the component according to the planned dimension is known as machining process . The common processes involved in this process are turning , planning, shaping , drilling , etc. SURFACE FINISHING PROCESS The process used to provide a good surface finish for the components are called as surface finishing process . The common operations used for this process are polishing , buffing , abrasive belt grinding , super finishing etc.

- 13. JOINING PROCESS The processes used to join the components are known as joining process . The common operations used for this process are welding , riveting , brazing , screw fastening, pressing etc. GENERAL PROCEDURE OF DESIGN RECOGANISATION OF NEED First of all, make a complete statement of the problem, indicating the Need, aim or purpose for which is to be designed . SYNTHESIS(MECHANISM) Select the possible mechanism or group of mechanism which will give the desired motion. ANALYSIS OF FORCES Find the forces acting on the each member of the machine and energy transmitted by the each member. MATERIAL SELECTION Select the material best suited for each member of the machine.

- 14. DESIGN OF ELEMENTS (SIZE AND STRESSES) Find the size of each member of the machine by considering the forces acting on member and the permissible stress for the material used. MODIFICATION Modify the size of the member to agree with the past experience and judgment to facilitate manufacture . The modification may also be necessary by consideration of manufacturing to reduce overall cost. DETAILED DRAWING Draw the detailed drawing of each component of each assembly of the machine with complete specification for the manufacturing process suggested PRODUCTION The component , as per the drawing , is manufactured in the workshop.

- 15. PROCESS CHART Part name operations Machine used Materials used 1Base The M.S plate of rough size is cut &shaped to finish size Gas cutting m/c Mild steel 2.Fixed arm The M.S square of rough size is cut & shaped to finish size Shaping m/c Drilling m/c Mild steel 3.Extended arm The M.S square is cut to require size. Gas cutting m/c Shaping m/c Forging m/c Mild steel 4.Hinged eye bolt & nut The M.S rod is turned faced & drilled to require diameter. Lathe Drilling & Threading Mild steel 5.Supporting arm The M.S square of rough size is cut & shaped to finish size Gas Cutting ,shaping m/c,drilling m/c Mild steel For assembling of parts, welding has been done where ever necessary

- 16. 6. PART DRAWING 1.Base Plate: 2. Extended Arm:

- 18. DESIGN CALCULATION 8.FABRICATION: Shafts are turned using lathe. Threads are cut using lathe. Bearing block drilling, boring using lathe. Extended arm bending by forging. Base plate drilling using mechanical hand driller. Base plates are cut using mechanical saw. Nut-cum-hanger is bent by forging.. 9.ASSEMBLY OF AUTOMATIC BABY CRADLE COMPONENTS: Base plate if fitted with steel plate Location of input shaft and output shaft sketched using pencil on the base plate. Motor is bolted to the baseplate. Bearing is fixed on the motor crank. Fixed arm is placed on base plate. Input and output shaft are tight fitted in the bearing Transformer connected in the L-angle Base plate is welded with steel plate Extended arm is fixed in the fixed arm.

- 20. PHOTOCOPY

- 21. COST ANALYSIS S.NO PART MATERIAL SPECIFICATION QUANTITY COST (RS) 1 Extended rod Mild steel Length=1200mm width=12mm 1 100 2 DC Motor 12V, 2 amps Rated speed=32- 52 rpm 1 400 3 Transformer 6V, 6-0-6, 2 amps 1 150 4 Fixed arm Mild steel Diameter=17mm Length= 50mm 1 30 5 Bearing High carbon steel Skf 6306 2 100 6 L-angle Mild steel Thickness=3mm 1 20 7 Base plate Mild steel 200*150*2mm 1 100 8 Bolts and nuts Mild steel M8 2 20 9 Machining cost 500 10 Total 1420

- 22. CONCLUSION: In this project, we have performed and understood the following Kinematic links placements were calculated. Base plate and fixed arm are designed theoretically. Mechanisms were designed practically.

- 23. Materials were selected for various components considering the design and the safety factors. We learned How to plan a process? How to relate theories to practical work? Lot of practical notions How to tackle difficulties practically and overcome it. Technical terms and notion used in workshop. We also conclude here by that, this cradle pleases the common family.This device reduces the major part in the art of babycaring. And we hope that our model will bring a pleasant atmosphere and an adorable maternal-child and a familyenvironment.