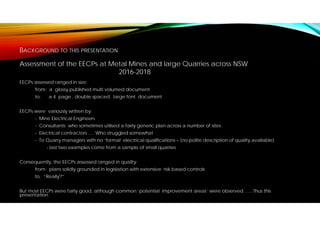

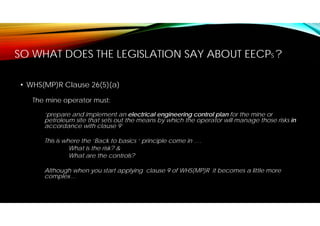

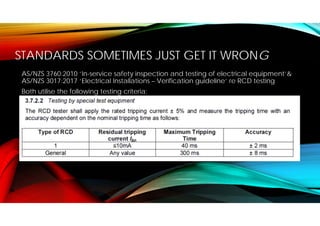

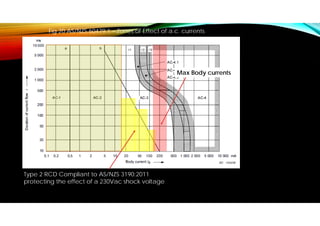

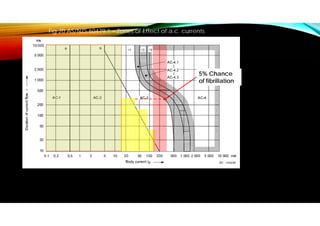

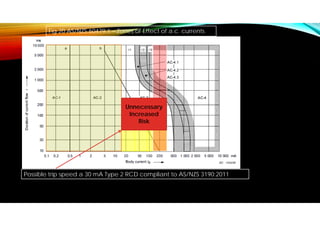

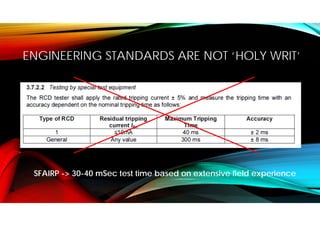

The document summarizes issues the presenter has observed with Electrical Engineering Control Plans (EECPs) at mines in NSW from 2016-2018. Many EECPs were developed by adapting older Electrical Engineering and Safety Management Plans (EESMPs) rather than starting with a new risk assessment. This can lead to EECPs that do not fully comply with legislation, apply the hierarchy of risk controls, or ensure risks are managed as far as reasonably practical. Standards are also limited and sometimes incorrect, so should not be solely relied upon. The presenter recommends EECPs undergo a new risk assessment process focused on the legislative requirements to develop improved electrical safety controls.